Preparation method of 1, 5-dichloro-2, 4-dinitrobenzene

A technology of dinitrobenzene and dinitrobenzene, which is applied in the field of compound preparation, can solve the problems of a large amount of waste acid environment, pollution, and high reaction temperature, and achieve the effect of low requirements for reaction equipment, abundant raw material sources, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

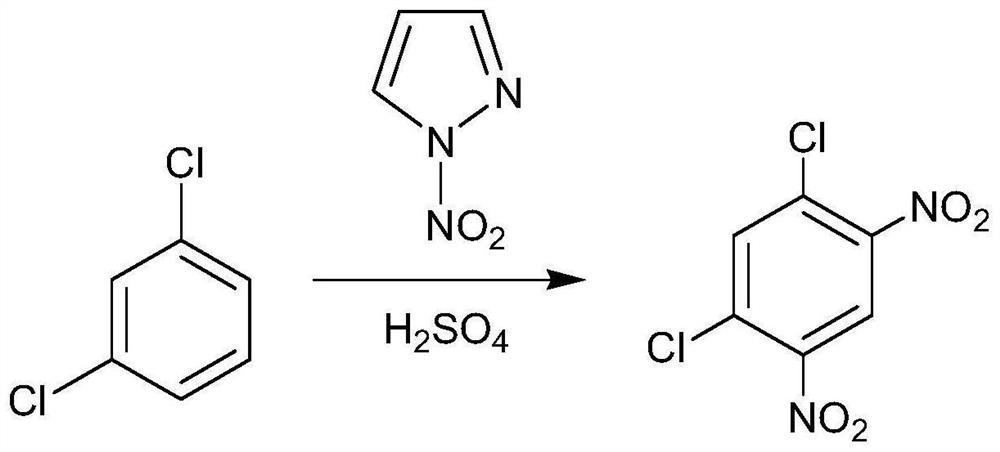

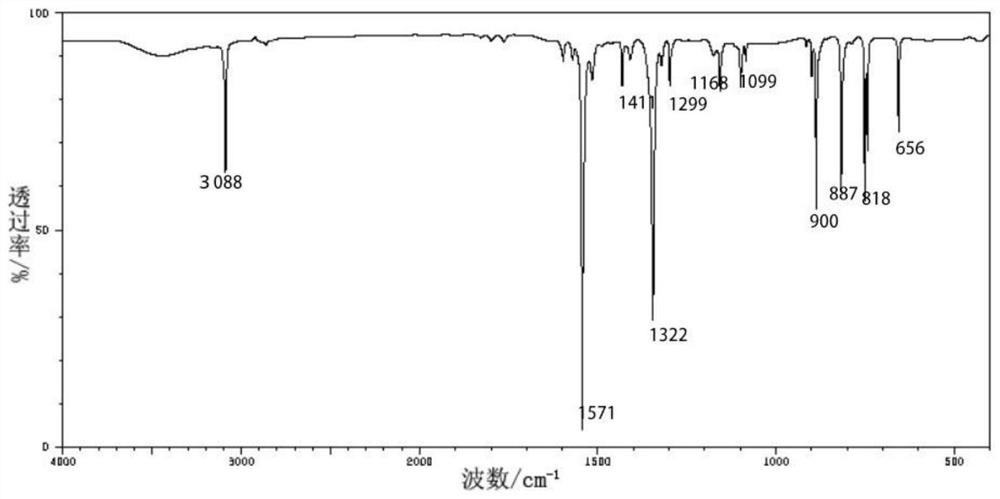

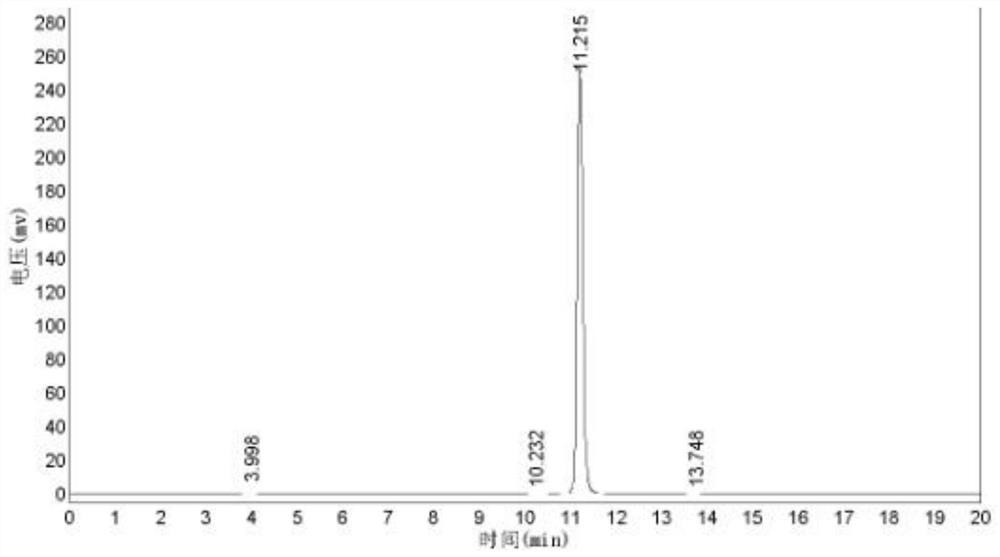

[0015] The embodiment of the present invention provides a preparation method of 1,5-dichloro-2,4-dinitrobenzene, using m-dichlorobenzene as raw material, N-nitropyrazole and H 2 SO 4 For the preparation of 1,5-dichloro-2,4-dinitrobenzene as a nitrating agent, the synthetic route is as follows figure 1 Shown; specifically include the following steps: take 8ml of 98% sulfuric acid in a four-necked flask, add m-dichlorobenzene 0.012mol dropwise to the concentrated sulfuric acid under mechanical stirring (300-400 rpm) at 20°C, and complete the addition in a water bath Raise the temperature to 60°C, add 0.024mol of N-nitropyrazole in batches at this temperature (the reaction system will heat up during the feeding process, and add again after the temperature drops to the initial temperature), keep stirring after the feeding is completed, and react at a constant temperature of 65°C 6h, while hot, pour the reaction solution into a container with ice cubes and stir to reduce the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com