Ytterbium-containing near-infrared ultra-long-afterglow gallate luminescent material and preparation method thereof

A technology of afterglow gallate and luminescent material, applied in luminescent materials, chemical instruments and methods, etc., can solve the problem of limited afterglow performance of gallate magnetoplumbite, achieve excellent afterglow performance, simple preparation process, and easy technical popularization and the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

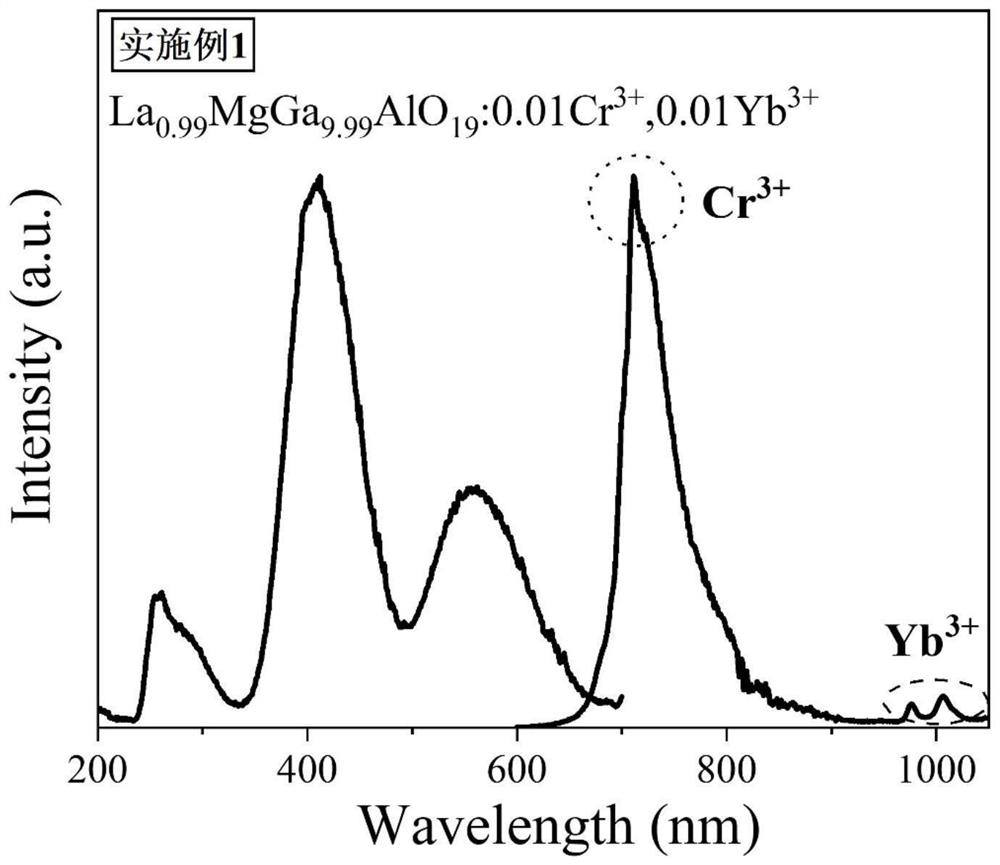

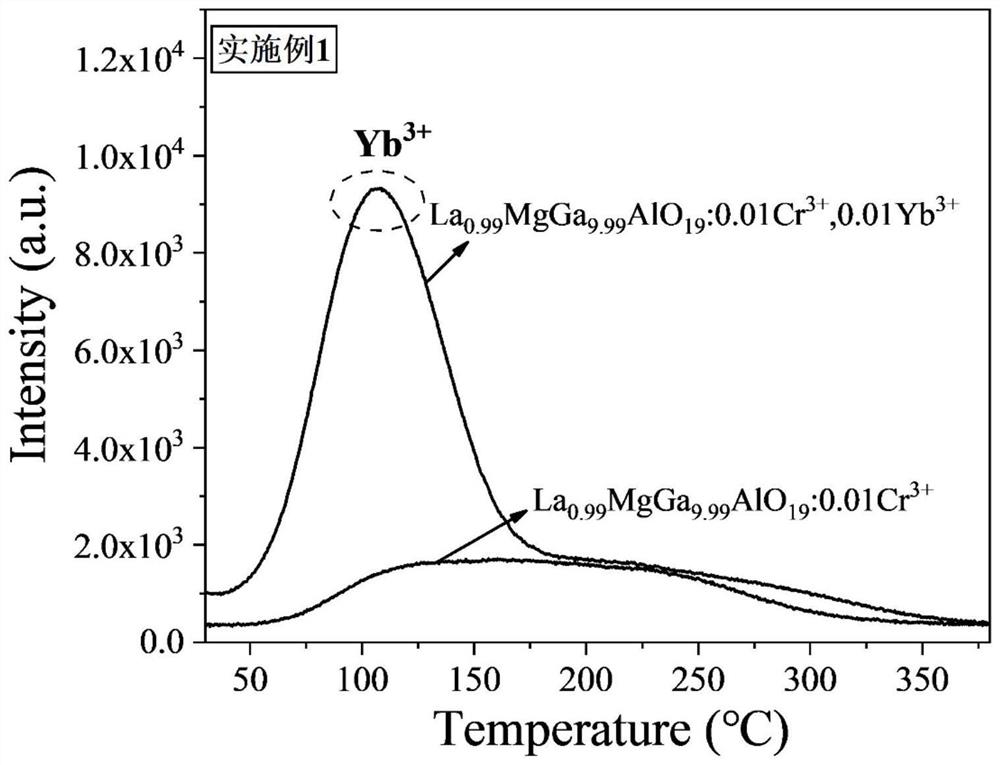

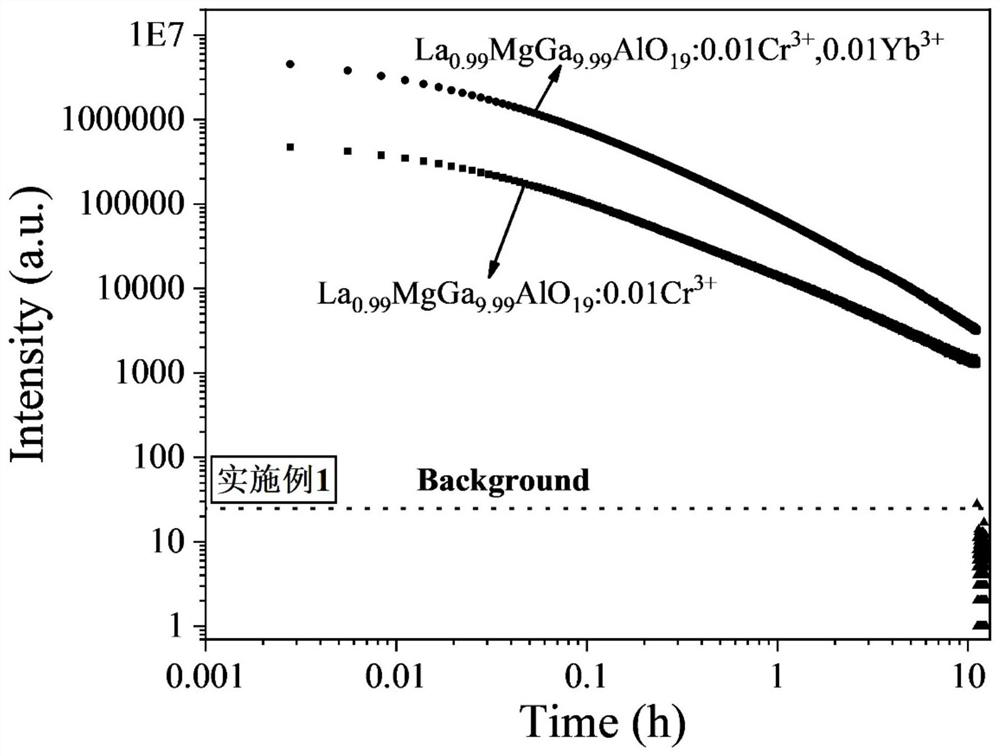

[0036] According to the inorganic chemical formula La 0.99 MgGa 9.99 AlO 19 :0.01Cr 3+ ,0.01Yb 3+ The stoichiometric ratio, in turn weigh 2.304g of La 2 o 3 , 0.576g of MgO, 13.375g of Ga 2 o 3 , 0.728g Al 2 o 3 , 0.011g Cr 2 o 3 , 0.028g Yb 2 o 3 High-purity powder raw material, adding 2% by weight of H 3 BO 3 The powder was used as a co-solvent for the reaction, and all the powder raw materials were placed in an agate mortar. Add a small amount of alcohol and grind for 20 minutes. After the raw materials are fully mixed, transfer the mixture into an alumina ceramic crucible, transfer it to a high-temperature box furnace, raise the temperature to 1400 degrees at a heating rate of 5 degrees per minute, and keep it warm for 5 hours. Furnace cool to room temperature. The obtained block sample is fully ground into powder again to obtain a compound with chemical composition formula La 0.99 MgGa 9.99 AlO 19 :0.01Cr 3+ ,0.01Yb 3+ Near-infrared long afterglow lum...

Embodiment 2

[0040] According to the inorganic chemical formula La 0.98 ZnGa 9.495 al 1.5 o 19 :0.005Cr 3+ ,0.02Yb 3+ The stoichiometric ratio, in turn weigh 2.281g of La 2 o 3 , 0.203g ZnO, 12.712g Ga 2 o 3 , 1.092g Al 2 o 3 , 0.005g Cr 2 o 3 , 0.056g Yb 2 o 3 The high-purity powder raw materials were added with 1% by weight LiF as a reaction co-solvent, and all the powder raw materials were placed in an agate mortar. Add a small amount of alcohol and grind for 15 minutes. After the raw materials are fully mixed, transfer the mixture into an alumina ceramic crucible, transfer it to a high-temperature box furnace, raise the temperature to 1350 degrees at a heating rate of 5 degrees per minute, and keep it warm for 5 hours. Furnace cool to room temperature. The obtained block sample is fully ground into powder again to obtain a compound with chemical composition formula La 0.98 ZnGa 9.495 al 1.5 o 19 :0.005Cr 3+ ,0.02Yb 3+ Near-infrared long afterglow luminescent materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com