Intelligent anti-blocking device and method for large blast furnace injection system based on spectrum analysis

A spectrum analysis, large-scale technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as easy blockage, low degree of automation, and low injection efficiency, and achieve the goals of reducing the probability of blockage, high reliability, and improving injection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

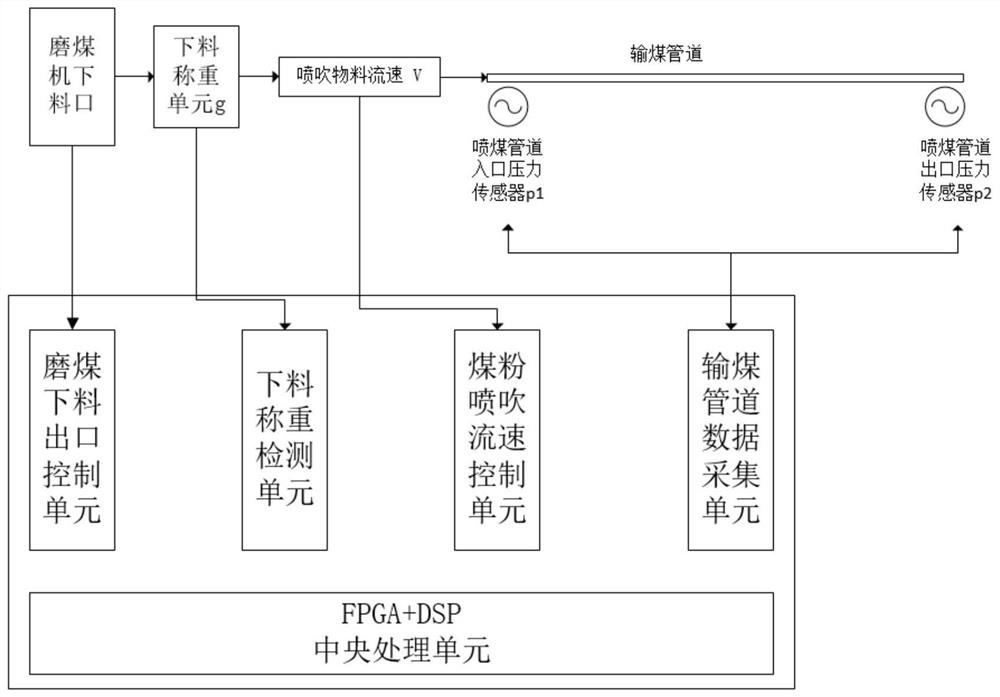

[0030] like figure 1 As shown in the figure, in the injection system of the present invention, a feeding control unit and a material weighing control unit are set at the feeding port of the coal mill, and the latter stage is connected to the injection flow rate control unit, and the injection rate is V; Two pressure sensors are installed at the outlet respectively, and the collected pressure values are p1 and p2; the centralized control device is equipped with a central processing unit of FPGA+DSP, which collects the pressure collection unit of the coal conveying pipeline, the injection material flow rate control unit, and the blanking weighing. Unit, blanking control unit; the central processing unit collects the sensor signal processing of each sub-unit module, and according to the internal judgment logic, the signal output of each contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com