Fuel reaction device for vanadium-titanium blast furnace and use method of fuel reaction device

A technology of fuel reaction and blast furnace, which is applied in the direction of blast furnace, blast furnace details, blast furnace parts, etc., can solve the problems of low cost, poor effect of fuel mixed reaction, and failure to reach, etc., to achieve the effect of high speed, high quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

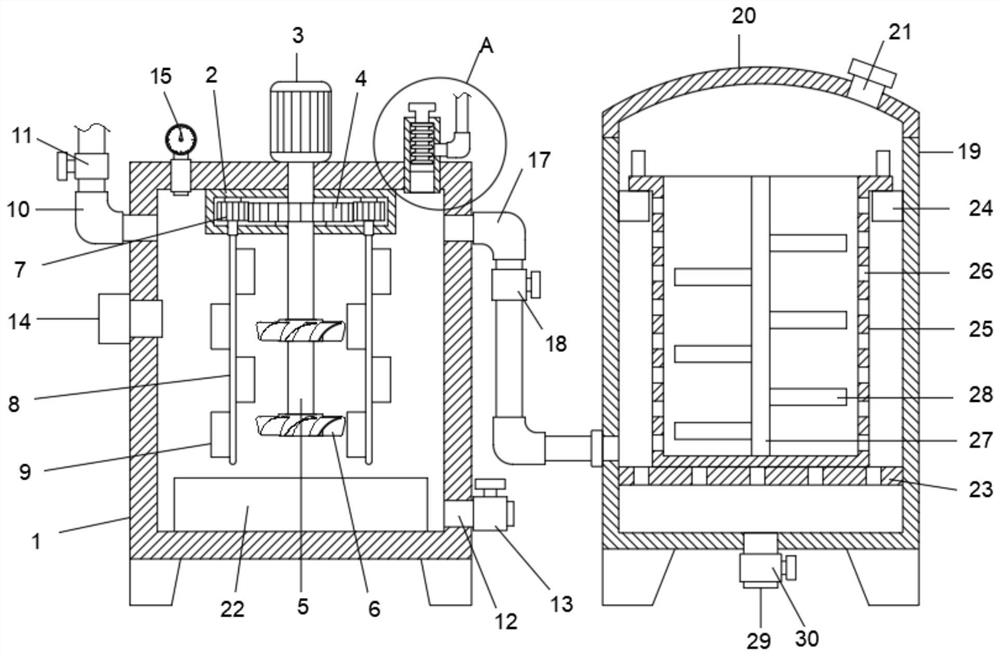

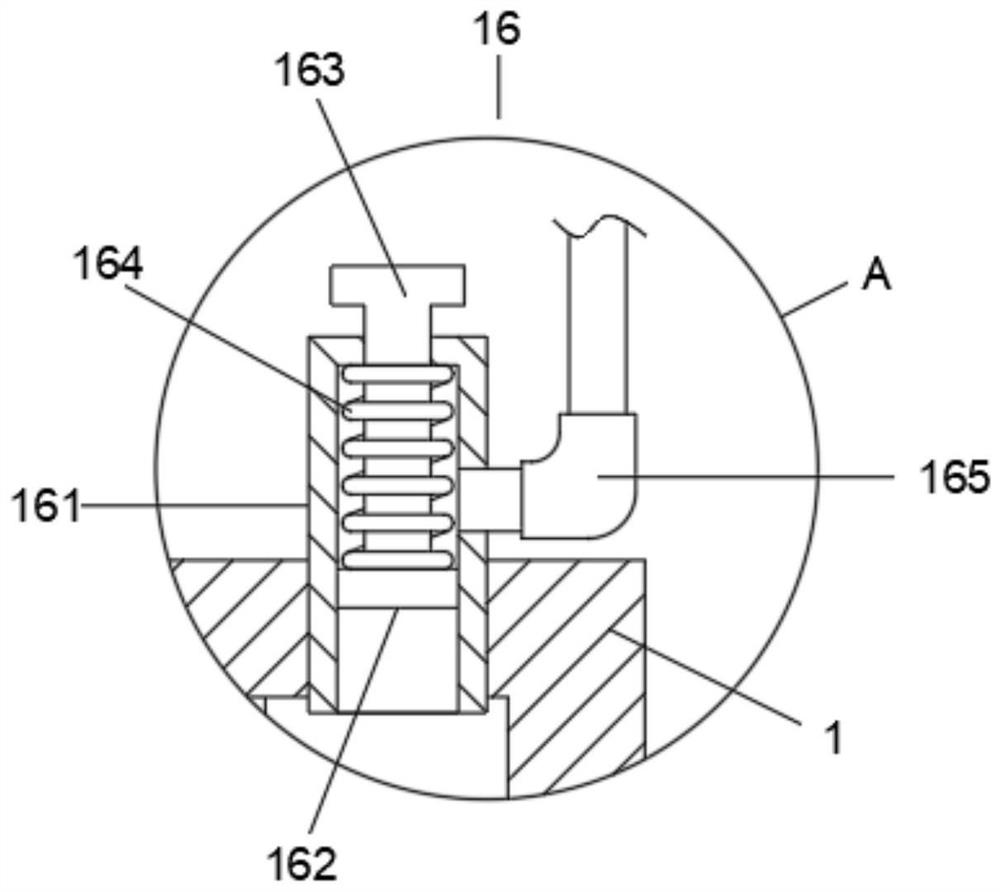

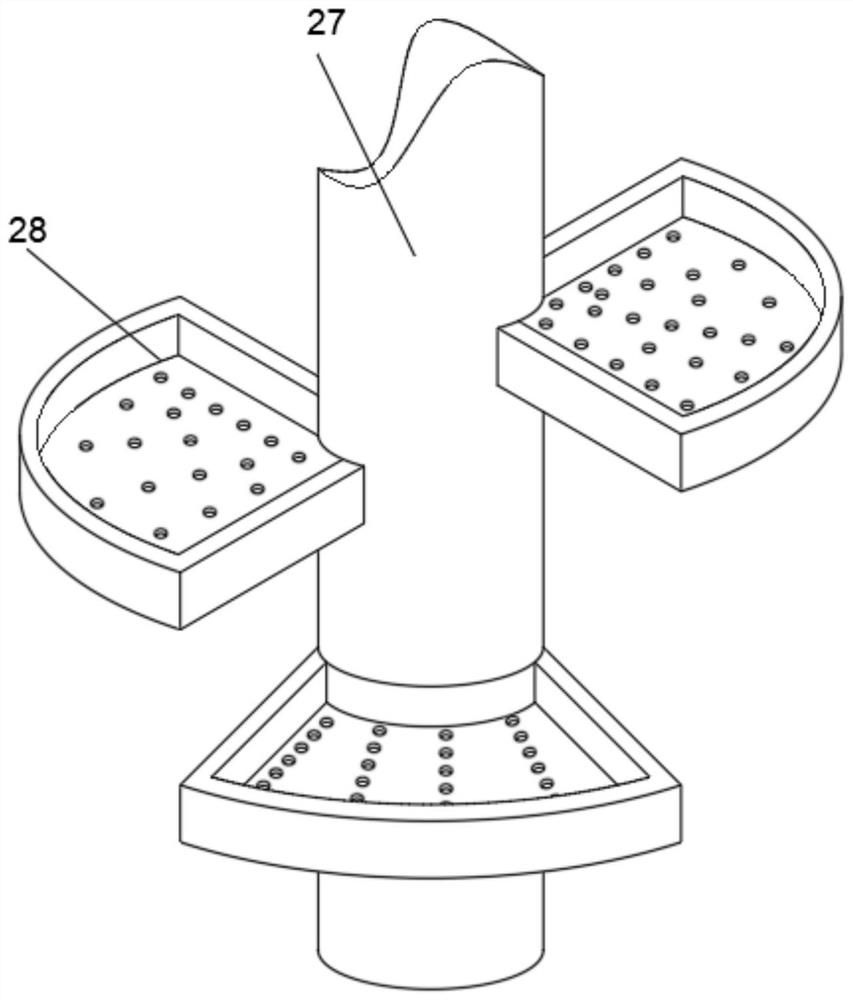

[0026] A fuel reaction device for a vanadium-titanium blast furnace, including a mixing tank 1, a servo motor 3, an exhaust assembly 16, a reaction kettle 19, and a material barrel 25. The top of the inner wall of the mixing tank 1 is fixedly connected to a gear box 2, and the top of the mixing tank 1 is fixed A servo motor 3 is connected, and the output end of the servo motor 3 is fixedly connected with a rotating shaft 5. The bottom end of the rotating shaft 5 extends through the gearbox 2 to the inside of the mixing tank 1, and the outer part of the rotating shaft 5 is symmetrically fixedly connected with a mixing fan 6, which can control the mixing tank 1. The internal reaction substances are mixed, the bottom of the inner wall of the mixing tank 1 is fixedly connected with a heater 22, the outside of the mixing tank 1 and the side away from the servo motor 3 is fixedly connected with a drain pipe 12, and the outside of the drain pipe 12 is fixedly connected with a No. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com