LPG gas-liquid separation tank and fuel control system

A gas-liquid separation tank and fuel control technology, applied in the field of ship LPG power system, can solve the problems of easy overpressure, inability to meet the use of LPG fuel, incompressible liquid, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

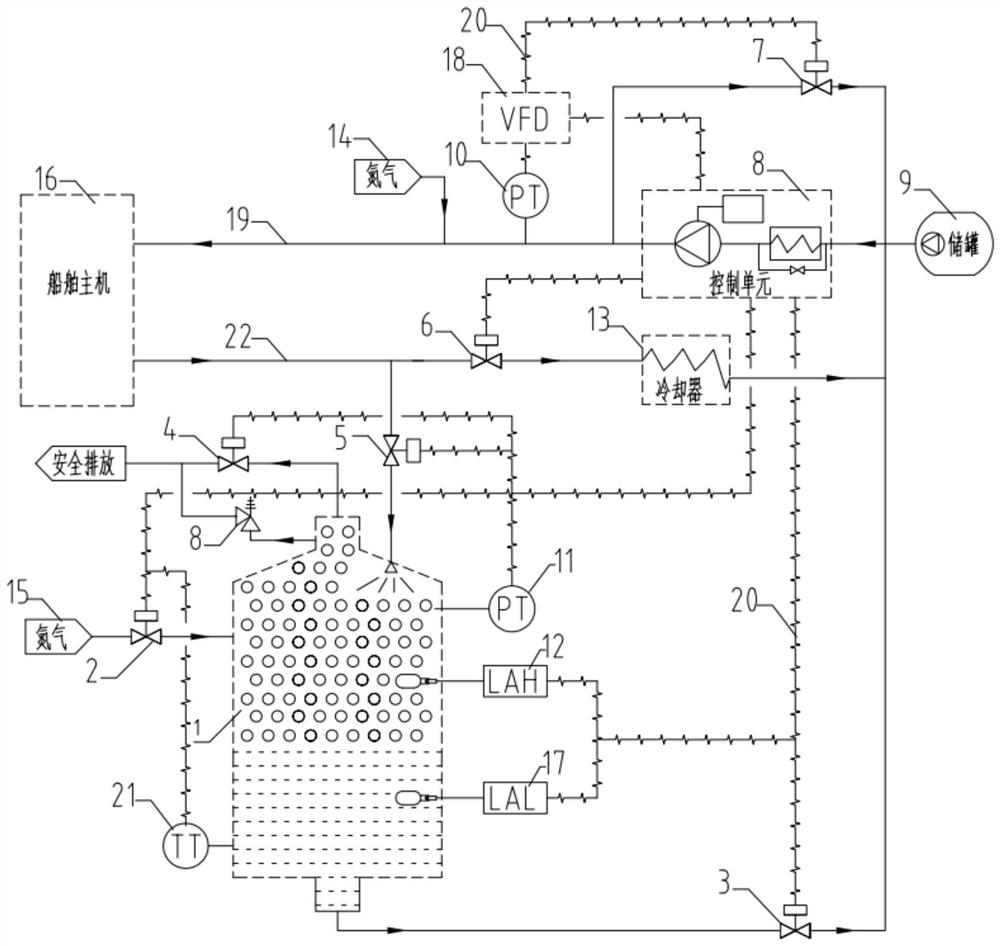

[0023] see figure 1 , an LPG gas-liquid separation tank and fuel control system, divided into a gas-liquid separation tank part and a fuel supply part, the gas-liquid separation tank part includes a gas-liquid separation buffer tank 1, a second nitrogen supply pipe 15, and a set of control signal lines 20 and a fuel supply control unit 8, the pipeline between the gas-liquid separation buffer tank 1 and the second nitrogen supply pipe 15 is provided with a first remote control proportional valve 2, the inside of the tank body of the gas-liquid separation buffer tank 1 A first liquid level alarm switch 12 and a second liquid level alarm switch 17 are fixedly installed, and a second pressure sensor 11 and a temperature sensor 21 are also arranged inside the tank body of the gas-liquid separation buffer tank 1. The external pipeline branch of the tank 1 is provided with a second remote proportional valve 3, a third remote proportional valve 4 and a fourth remote proportional valve...

Embodiment 2

[0027] Using a kind of LPG gas-liquid separation tank and fuel control system described in Embodiment 1, the control system is specifically operated. Before the LPG-powered ship main engine 16 is started for the first time, the first step needs to be purged with nitrogen to remove the pipe. The natural air, moisture and other impurities in the pipeline will inert the interior of the pipeline to prevent LPG from directly entering the pipeline and forming an explosive mixture with natural air. In the second step, the nitrogen in the pipeline needs to be replaced with LPG, and in the third step, the main engine 16 of the LPG-powered ship can be started. After shutting down, it is necessary to replace the LPG in the pipeline with nitrogen. Regardless of startup or shutdown, the displaced gas-liquid mixture needs to be collected in the gas-liquid separation buffer tank 1 and processed. The mixture of nitrogen and LPG in the collection pipeline has been replaced with each other. Due...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com