Lignite transient dehydration upgrading and temperature and pressure instant generating device system

A generation system, lignite technology, applied in the direction of drying gas arrangement, drying solid materials, dryers, etc., can solve the problems of poor dehydration effect, easy spontaneous combustion, easy reabsorption, etc., to achieve large processing capacity, reduce reabsorption, and flow simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

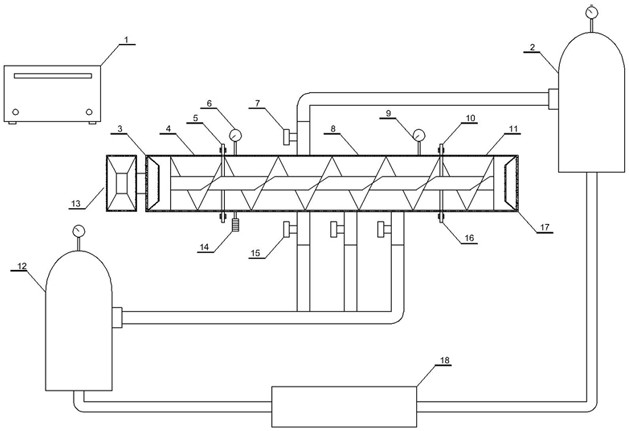

[0019] A lignite transient dehydration upgrading and temperature-pressure instantaneous device system is composed of a steam generation system 2 , a steam dehydration system, a steam recovery system 12 and a tail gas purification device 18 . The material is fed through the feeding device above the steam dehydration system, and the material enters the feeding area 4. At this time, the sealing valves 3 and 17 are opened, and the internal material platform is rotated forward. The wet material enters the dehydration area 8, and the material enters and then seals the valve 3, 17 off. Saturated steam is added in from the steam generation system 2 through the inlet valve 7, adjusted to a high temperature and high pressure state, and the pressure is maintained for a certain period of time. During this stage, the saturated water vapor takes away the moisture inside the material through gas-liquid exchange, and the pressure relief valve 15 Instantaneous pressure release to normal temper...

Embodiment 2

[0021] The lignite contains water before dehydration, and the material is fed through the feeding device 13 above the steam dehydration system, and the material enters the feeding area 4. At this time, the sealing valves 5 and 10 are opened, and the internal material platform is rotated forward, and the lignite enters the dehydration area 8. After dehydration The lignite enters and then the sealing valves 5, 10 are closed. Saturated steam is added from the steam generation system, and then adjusted to 2 MPa by the pressure sensing devices 6 and 9 of the electronic control system 1 to stabilize the pressure. In this stage, the saturated water vapor takes away the internal moisture of the lignite through gas-liquid exchange, and then the electric control system The pressure relief valve 14 is controlled to release the pressure instantaneously to normal temperature and pressure, and the internal steam will explode to destroy the lignite pores, and then be introduced into the steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com