Long-life micro-column array graphite and metal composite cathode structure and preparation method thereof

A technology of microcolumn array and graphite cathode, which is applied in the field of composite cathode structure and preparation of long-life microcolumn array graphite and metal for maser, can solve the problem of losing stable electron beam emission, reducing beam coupling efficiency, losing Problems such as the raised launch structure can improve the ability to work stably for a long time, reduce the generation of plasma, and solve the effect of random changes in the launch position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

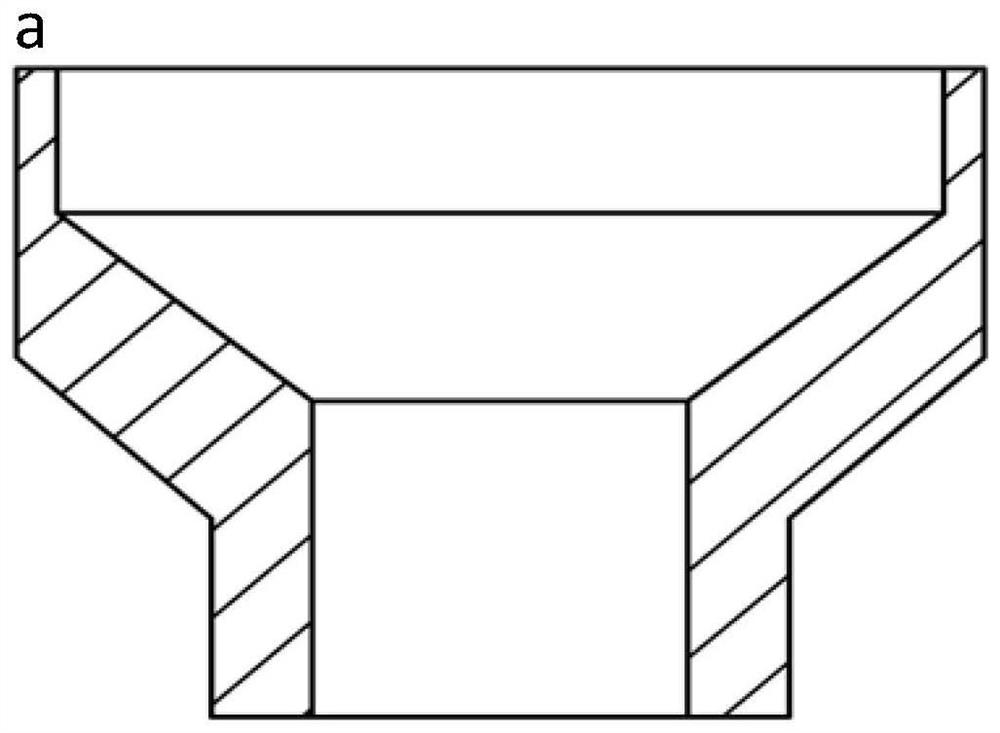

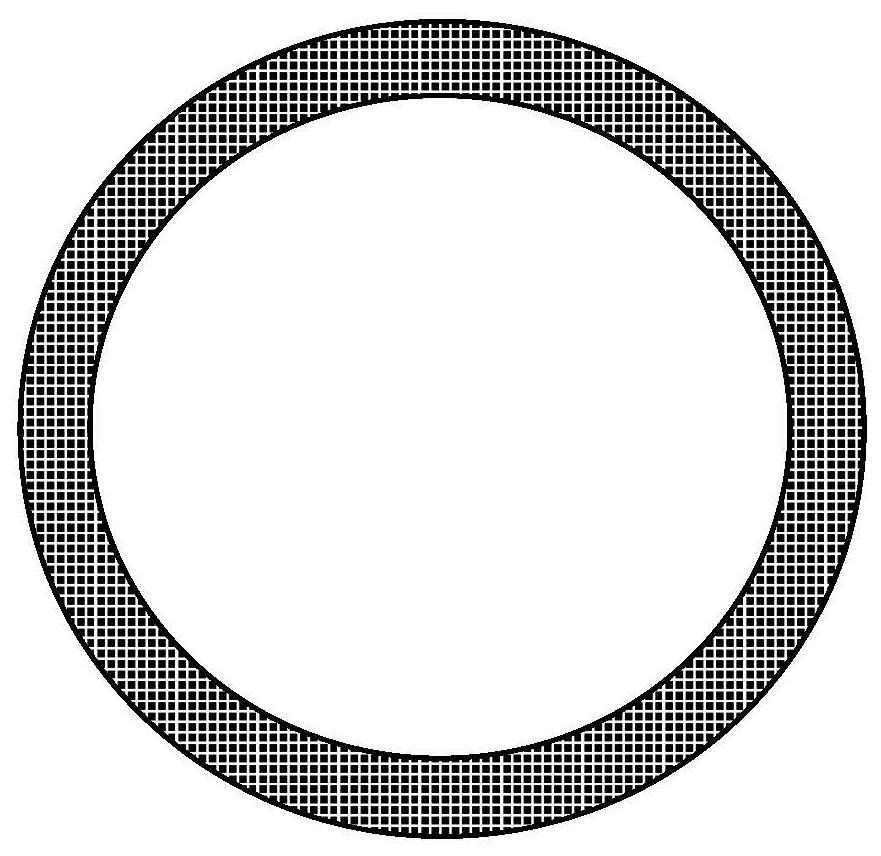

[0039] 1) the graphite is processed into a knife-edge annular graphite cathode substrate, the outer diameter of the knife-edge annular graphite cathode substrate (i.e. the diameter of the outer ring) is 50 mm, and the wall thickness (i.e. the radius of the outer ring minus the radius of the inner ring) is 1 mm; Ultrasonic cleaning in ethanol and drying in an oven for later use;

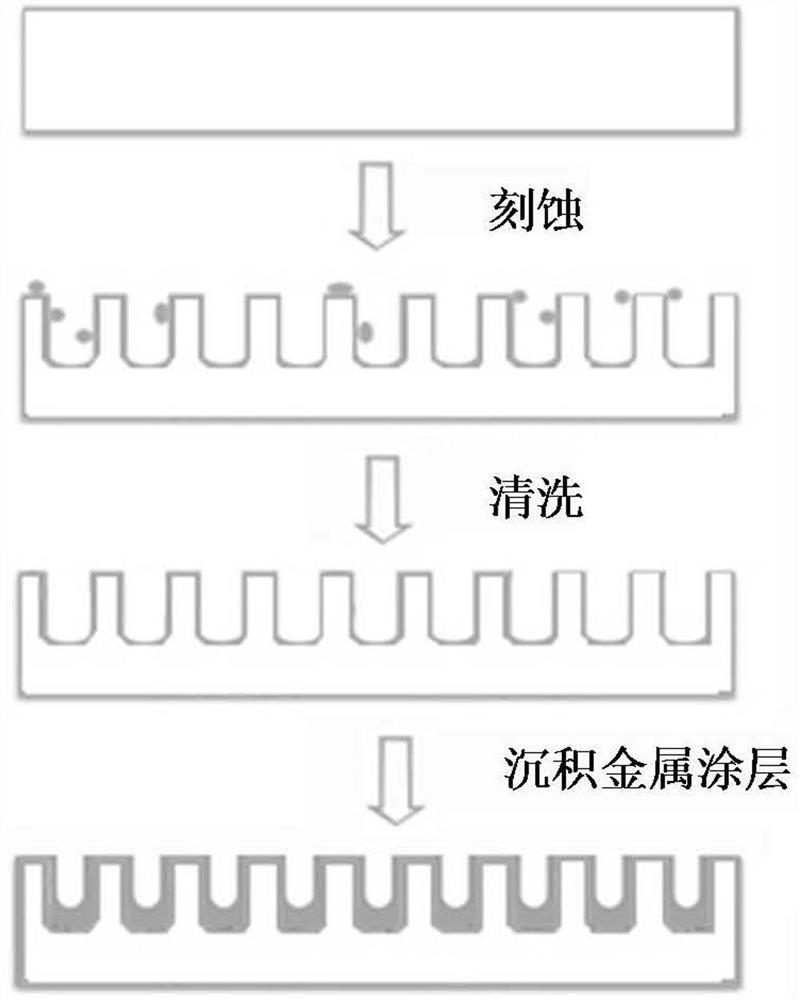

[0040] 2) By ultraviolet laser etching, a graphite microcolumn array is constructed on the surface of the knife edge of the dried knife-edge annular graphite cathode substrate. The diameter of the graphite microcolumn is 20 μm, and the ratio of height to diameter is 6:1. The distance between the micro-column axes is 60 μm, and the graphite cathode of the micro-column array is obtained, which is cleaned with low-power ultrasonic in ethanol to remove the debris around the graphite micro-column, and dried in an oven for later use;

[0041] 3) Place the dried microcolumn array graphite cathode in a chemic...

Embodiment 2

[0047] 1) the graphite is processed into a knife-edge annular graphite cathode substrate, the outer diameter of the knife-edge annular graphite cathode substrate (i.e. the diameter of the outer ring) is 100 mm, and the wall thickness (i.e. the radius of the outer ring minus the radius of the inner ring) is 1.5 mm; Ultrasonic cleaning in ethanol and drying in an oven for later use;

[0048] 2) By ultraviolet laser etching, a graphite microcolumn array is constructed on the surface of the knife edge of the dried knife-edge annular graphite cathode substrate. The diameter of the graphite microcolumn is 40 μm, and the ratio of height to diameter is 5:1. The distance between the micro-column axes is 100 μm, and the graphite cathode of the micro-column array is obtained, which is cleaned with low-power ultrasonic in ethanol to remove the debris around the graphite micro-column, and dried in an oven for later use;

[0049] 3) Place the dried microcolumn array graphite cathode in a ch...

Embodiment 3

[0054] 1) the graphite is processed into a knife-edge annular graphite cathode substrate, the outer diameter of the knife-edge annular graphite cathode substrate (i.e. the diameter of the outer ring) is 50 mm, and the wall thickness (i.e. the radius of the outer ring minus the radius of the inner ring) is 1 mm; Ultrasonic cleaning in ethanol and drying in an oven for later use;

[0055] 2) By ultraviolet laser etching, a graphite microcolumn array is constructed on the surface of the knife-edge annular graphite cathode substrate after drying. The diameter of the graphite microcolumn is 5 μm, and the ratio of height to diameter is 20:1. The adjacent graphite The distance between the micro-column axes is 20 μm, and the graphite cathode of the micro-column array is obtained, which is cleaned with low-power ultrasonic in ethanol to remove the debris around the graphite micro-column, and placed in an oven to dry for later use;

[0056] 3) Place the dried microcolumn array graphite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com