Rock sample high-precision cutting equipment and method

A technology of rock samples and cutting equipment, which is applied in the direction of stone processing equipment, test sample preparation, sampling, etc., can solve the problems of poor cutting accuracy, inability to adjust the cutting thickness accurately, and low cutting efficiency, so as to reduce grinding time and improve Sample preparation efficiency and good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

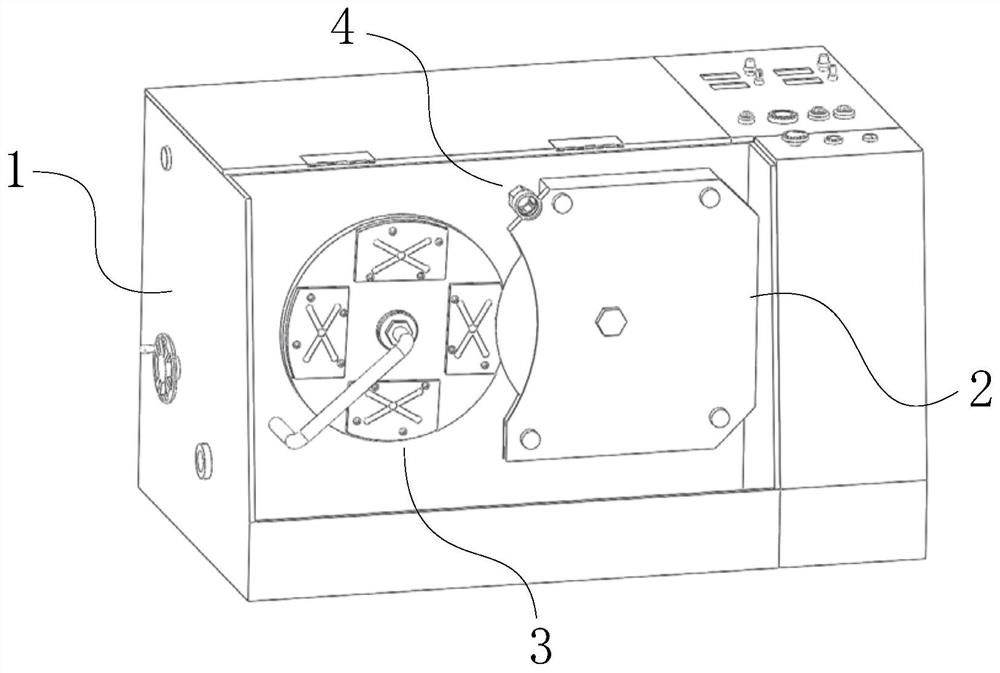

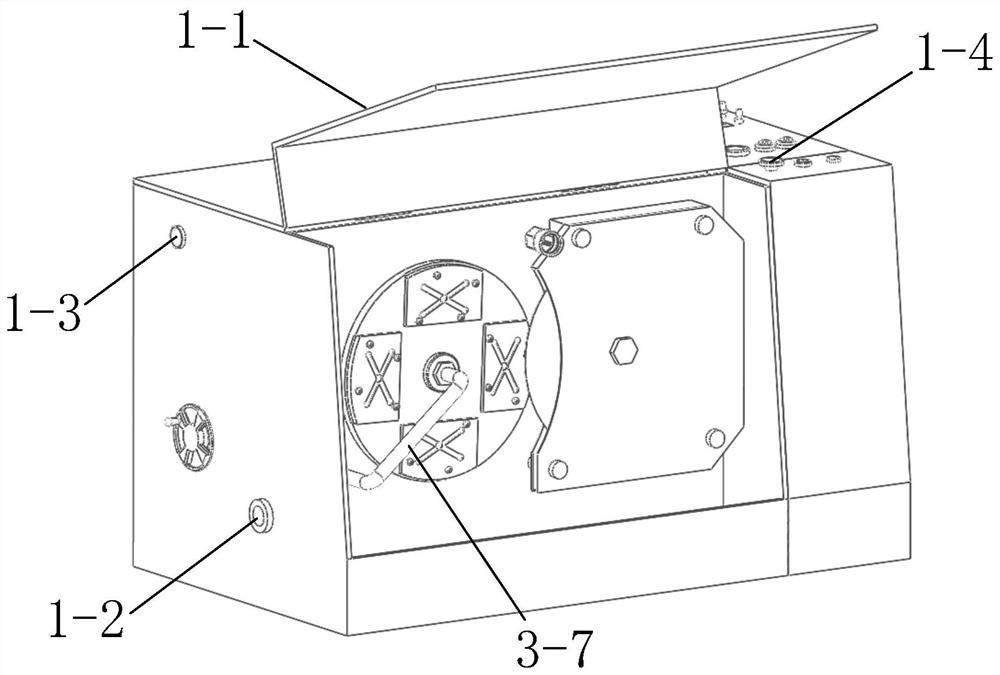

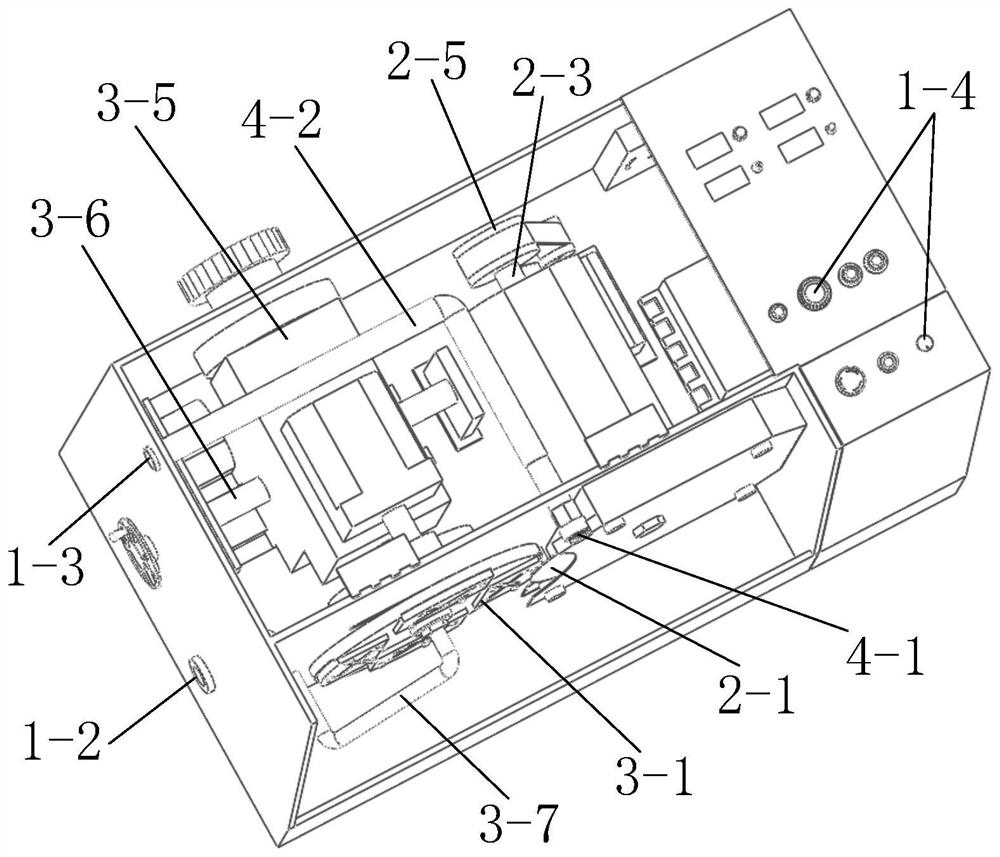

[0074] A specific embodiment of the present invention, such as Figure 1 to Figure 4 As shown, a rock sample high-precision cutting device is disclosed, including:

[0075] The cutting mechanism 2 includes a cutter head 2-1 and a first drive motor 2-2 for driving the cutter head 2-1 to rotate;

[0076] The clamping mechanism 3 includes a sample loading tray 3-1 and a driving mechanism. A plurality of sample mounting parts are evenly distributed on the sample loading tray 3-1. The samples to be cut are fixed on the sample mounting parts, and the driving mechanism is used to drive the sample loading tray 3-1. 1 Approaching or moving away from the cutter head 2-1 at a set speed while rotating;

[0077] The machine base 1, the cutting mechanism 2 and the rock sample clamping mechanism 3 are arranged on the machine base 1.

[0078] When cutting, the rock sample is fixed on the glass slide, and then the glass slide is fixed on the sample mounting part on the sample tray 3-1; -1 r...

Embodiment 2

[0108] Since the thickness of the rock samples to be cut is mostly 1-2cm, and the lateral movement speed of the sample loading plate 3-1 and the rotation speed of the cutter head 2-1 during the cutting process will affect the cutting effect, especially when the cutting starts instantaneously, if the sample loading If the transverse speed of the disk 3-1 is too fast, it will easily cause the rock sample to be cut to crack, resulting in the failure of cutting the sample. Therefore, it is necessary to control the advancing speed and rotation speed of the sample-carrying disc 3-1 at the moment of cutting and during the cutting process. The transverse propulsion speed of the sample-carrying disc 3-1 should be slow and maintain a stable transverse propulsive speed during the cutting process. However, there is a certain distance between the initial position of the sample-carrying disc 3-1 and the cutter head 2-1. If the device starts to move laterally at a slow speed, the sample-carry...

Embodiment 3

[0116] Another specific embodiment of the present invention discloses a method for high-precision cutting of rock samples, using the high-precision cutting equipment for rock samples in Embodiment 1 or 2, specifically including the following steps:

[0117] Step 1: Fix the rock sample to be cut on the glass slide.

[0118] Paste and fix the cube-shaped rock sample to be cut on the first side of the glass slide, and load the glass slide containing the rock sample to be cut into the adsorption installation groove 3-1-1 of the sample tray 3-1, the glass The second side of the slide is in contact with the adsorption surface of the adsorption installation groove 3-1-1;

[0119] Step 2: Start the vacuum device, and stably adsorb the glass slide on the sample loading tray 3-1 by means of vacuum adsorption.

[0120] Use a vacuum pump to extract the gap between the glass slide and the adsorption installation groove 3-1-1 and the air in the vacuum tube, and the internal passage forms a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com