A device and method for producing polymer nanofibers

A nanofiber and polymer technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problems of uneven spinning density, affecting production efficiency, poor spinning effect, etc., to reduce the electric field The effects of impact, easy implementation, and high spinning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

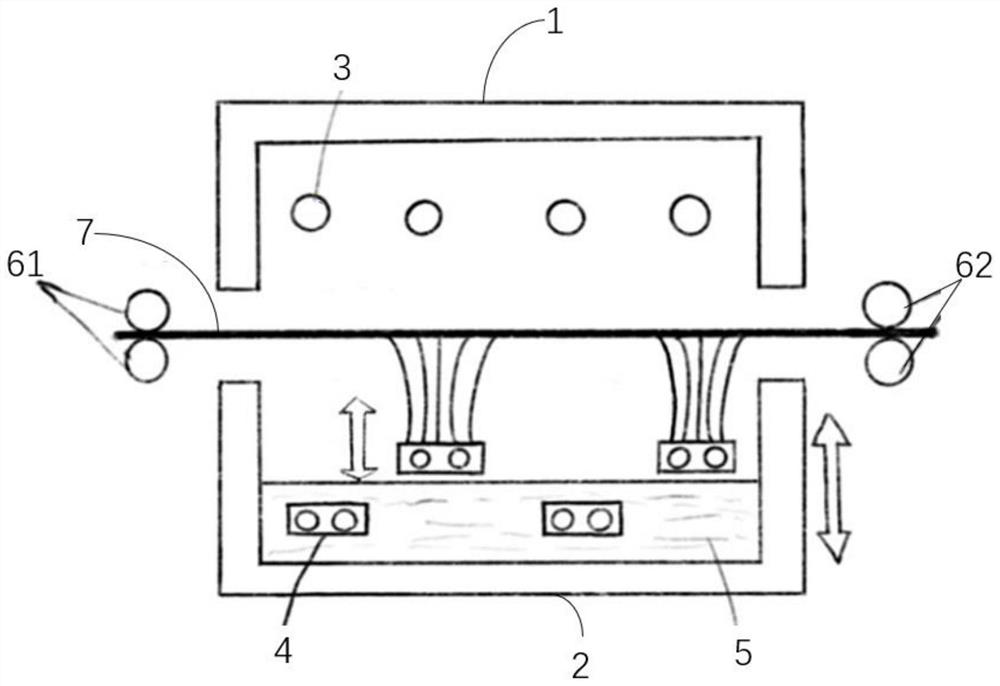

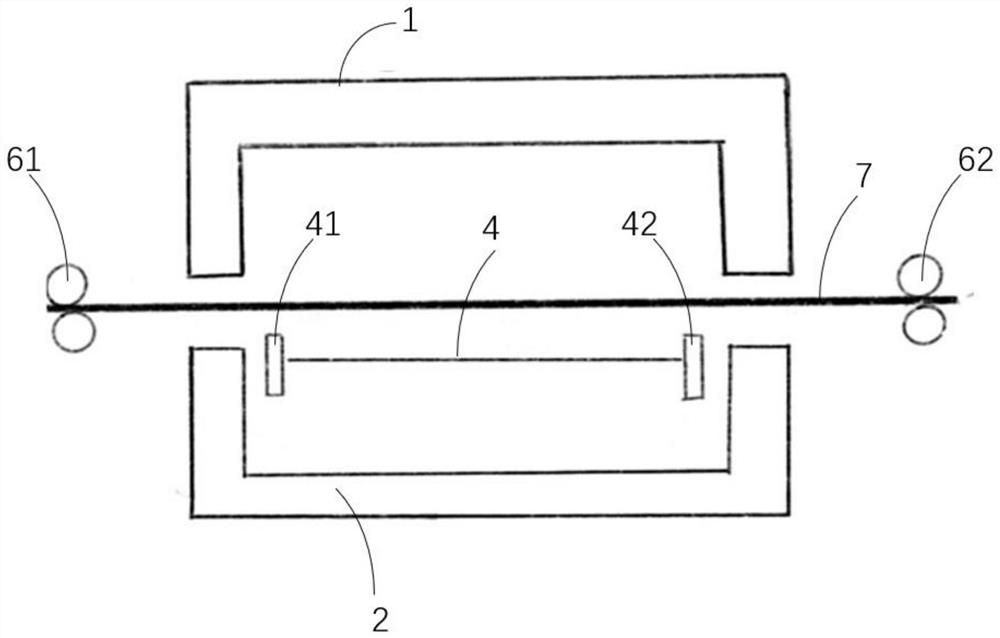

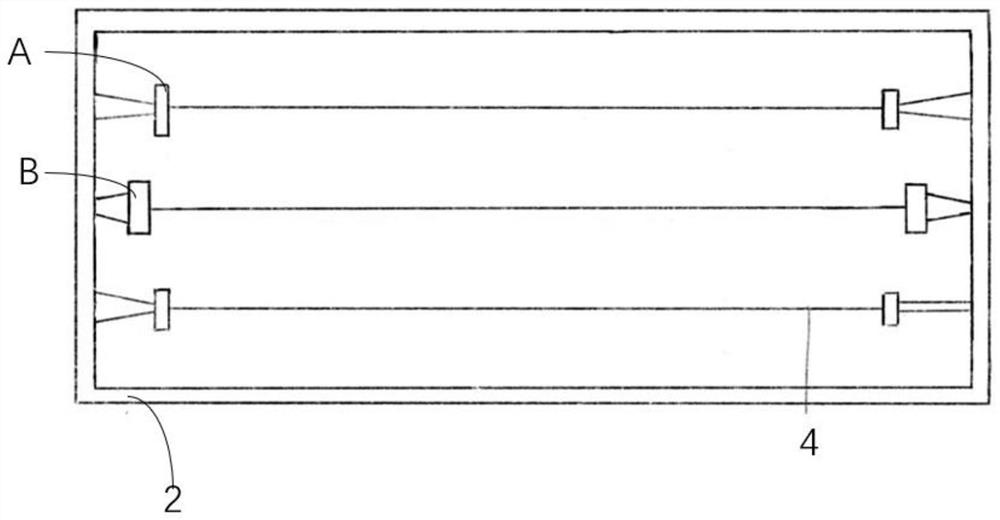

[0051] like Figures 1 to 5 As shown, a device for producing polymer nanofibers at least includes a liquid tank 2, a receiving device 7, and several first electrodes 3 and several second electrodes 4 that form a potential difference.

[0052] The receiving device 7 includes a substrate and several conveying assemblies. like figure 1 As shown, the conveying assemblies at both ends of the substrate include a first conveying assembly 61 and a second conveying assembly 62 . For example, both ends of the substrate are controlled by at least two pairs of unpowered rollers and are moved to receive the nanofibers ejected from the second electrode to form a nanofiber layer.

[0053] The moving state of the base material includes motion-related parameters such as stationary time, moving speed, moving time, and the like.

[0054] Preferably, several first electrodes 3 are arranged in the electrode chamber 1 . The arrangement of the plurality of first electrodes 3 is not limited, and ...

Embodiment 2

[0095] This embodiment is a further elaboration of Embodiment 1, and repeated content will not be repeated.

[0096] The present invention also provides a method for producing polymer nanofibers, the method comprising at least:

[0097] The substrate in the receiving device is arranged in such a way as to pass through the electric field between several first electrodes 3 and several second electrodes 4, or the substrate in the receiving device is arranged in the electric field, and at least one second electrode 4 is arranged in the same way as the electric field. The liquid tank 2 is dipped in the polymer solution by means of relative movement and spun to the receiving device 7 based on the action of the electric field to form a nanofiber layer.

[0098] The second electrode 4 is immersed in the polymer solution by intermittent energization.

[0099] When the second electrode 4 moves to contact the polymer solution in the liquid tank 2, the second electrode 4 is powered off, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com