Floating marine treatment barrel for oil-water separation

A technology of oil-water separation and oil-water separator, which is applied to the cleaning of open water surfaces, grain processing, general water supply conservation, etc., and can solve problems such as large ocean area, affecting water quality, and threatening marine biological systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

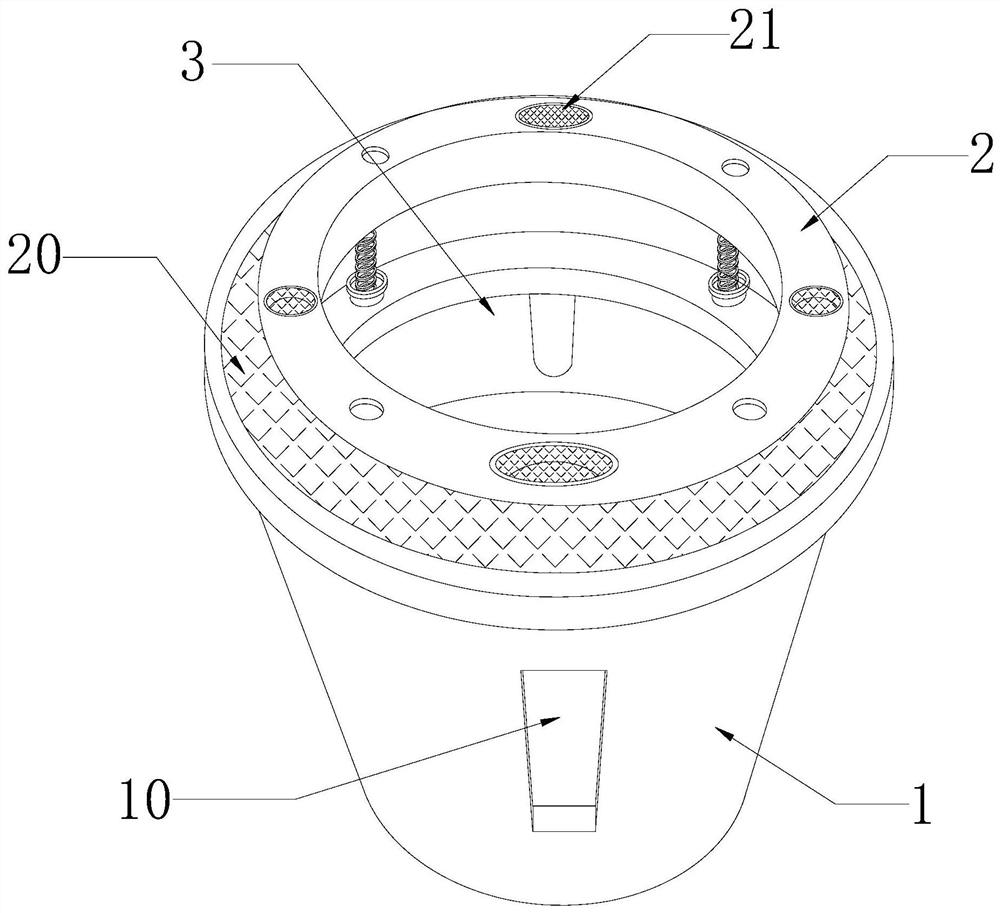

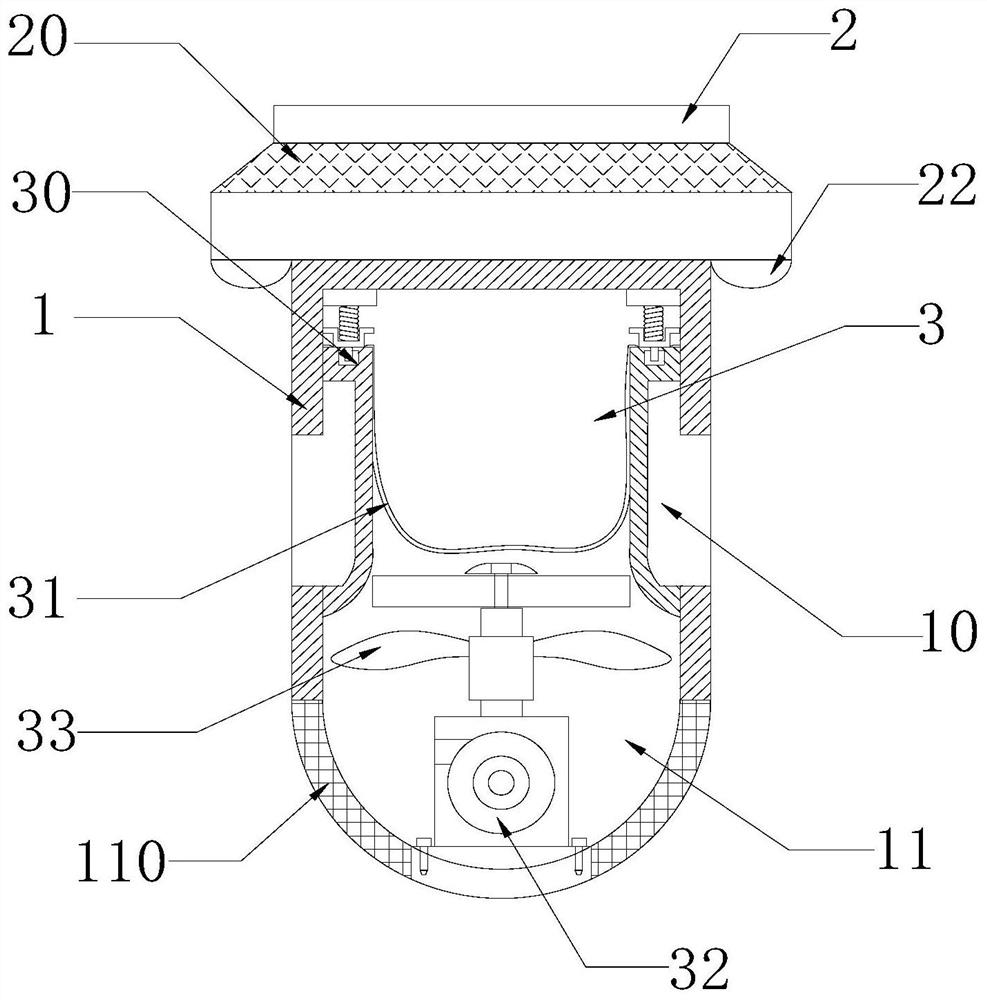

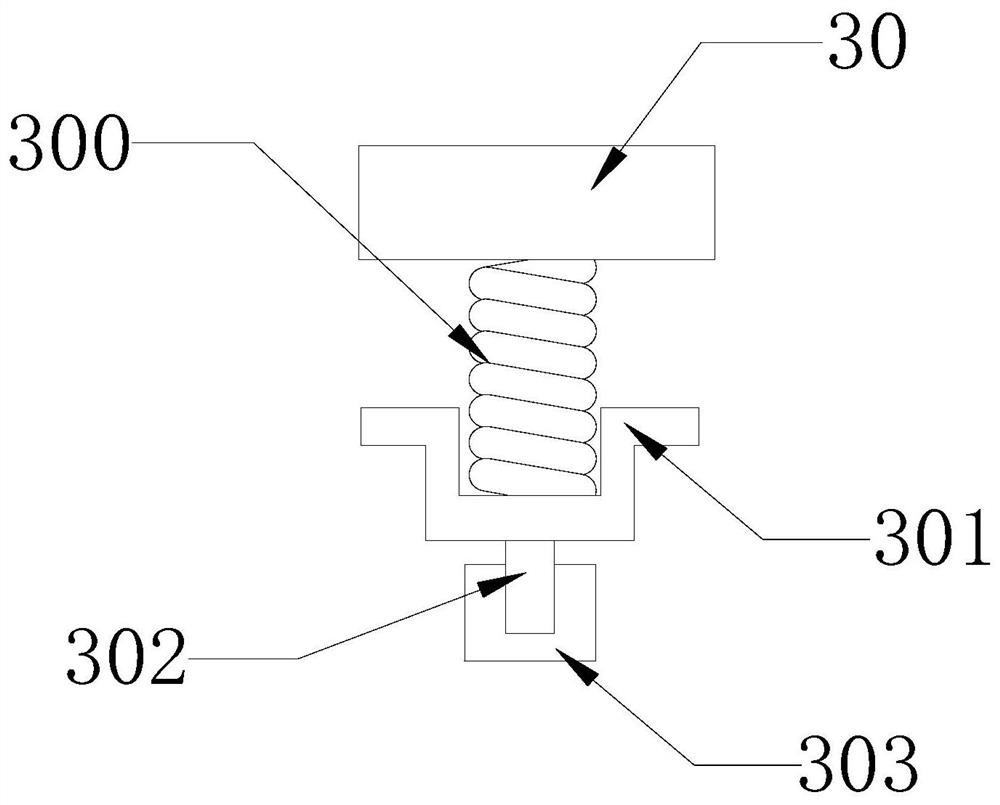

[0024] Embodiment: the airbag 22 at the bottom of the floating plate 2 enables the entire ocean processing barrel device to float on the water surface, and the motor 32 inside the filter chamber 11 drives the oil-water separator 33 to rotate. When the telescopic rod 330 on the oil-water separator 33 rotates Drive the crushing paddle 3301 and the sponge pad 331 to rotate, and when the crushing paddle 3301 rotates, a backflow vortex is generated, so that the plastic waste floating on the water surface is involved in the waste treatment chamber 3, and then a large area of waste is intercepted in the slag blocking net 31 In the net 31, the small area of garbage passes through the mesh of the slag blocking net 31, enters the filter chamber 11, and then rotates rapidly through the crushing paddle 33, and is crushed through the crushing groove A on the crushing paddle 33, and then the crushed garbage Discharge through the filter screen 110, so that the small area of plastic garb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com