Formation method of low-self-discharge lithium ion battery

A technology of lithium-ion battery and formation method, which is applied in the field of formation of low self-discharge lithium-ion battery, can solve the problems of not being able to meet the actual production requirements, battery internal resistance storage capacity and low cycle capacity, etc., so as to reduce self-discharge phenomenon, Effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

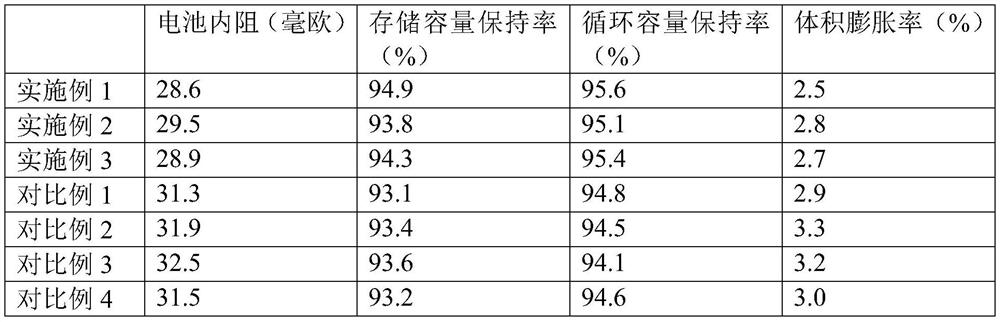

Embodiment 1

[0029] 1), inject electrolyte solution for the first time, the injected electrolyte solution accounts for 70% of the total electrolyte solution volume, and add 0.05mol / L dimethyl sulfone in the described electrolyte solution;

[0030] 2) Move the liquid-injected lithium-ion battery into the sealing device, fill the sealing device with nitrogen, adjust the temperature in the sealing device to 5°C, charge with a constant current of 0.001C for 10h; then charge with a current of 0.01C 10h;

[0031] 3), the battery in step 2) is taken out from the sealing device, and the electrolyte solution is injected for the second time, and 0.01mol / L sodium hexafluorophosphate is added to the electrolyte solution in the electrolyte solution;

[0032] 4) Move the liquid-injected lithium-ion battery into the sealing device, fill the sealing device with nitrogen gas, adjust the temperature in the sealing device to 25°C, charge at a constant current of 0.01C for 10h, and then charge at a current of...

Embodiment 2

[0038] 1), inject electrolyte for the first time, the injected electrolyte accounts for 80% of the total electrolyte volume, and add 0.1mol / L dimethyl sulfone in the electrolyte;

[0039] 2) Move the liquid-injected lithium-ion battery into the sealing device, fill the sealing device with nitrogen, adjust the temperature in the sealing device to 5°C, and charge at a constant current of 0.005C for 5 hours; then charge at a current of 0.03C 5h;

[0040] 3), the battery in step 2) is taken out from the sealing device, and the electrolyte is injected twice, and 0.005mol / L sodium hexafluorophosphate is added to the electrolyte;

[0041] 4) Move the injected lithium-ion battery into the sealing device, fill the sealing device with nitrogen gas, adjust the temperature in the sealing device to 25°C, charge at a constant current of 0.05C for 5 hours; charge at a current of 0.1C 5h;

[0042] 5) Adjust the temperature in the sealing device to 45°C, and charge to 4.2V with a constant cu...

Embodiment 3

[0047] 1), inject electrolyte for the first time, the injected electrolyte accounts for 75% of the total electrolyte volume, and add 0.08mol / L dimethyl sulfone in the electrolyte;

[0048] 2) Move the liquid-injected lithium-ion battery into the sealing device, fill the sealing device with nitrogen, adjust the temperature in the sealing device to 5°C, charge with a constant current of 0.003C for 5 hours; charge with a current of 0.02C 5h;

[0049] 3), the battery in step 2) is taken out from the sealing device, and the electrolyte is injected twice, and 0.008mol / L sodium hexafluorophosphate is added to the electrolyte;

[0050] 4) Move the injected lithium-ion battery into the sealing device, fill the sealing device with nitrogen gas, adjust the temperature in the sealing device to 25°C, charge with a constant current of 0.03C for 5h; charge with a current of 0.09C 5h;

[0051] 5) Adjust the temperature in the sealing device to 35°C, and charge to 4.2V with a constant curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com