Novel butterfly welding device

A butterfly, a new type of technology, applied in the field of new butterfly welding devices, can solve problems such as tab bumping, dry cell tab breakage, and difficult insertion into the shell, so as to improve product quality, reduce manual errors, and ensure consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

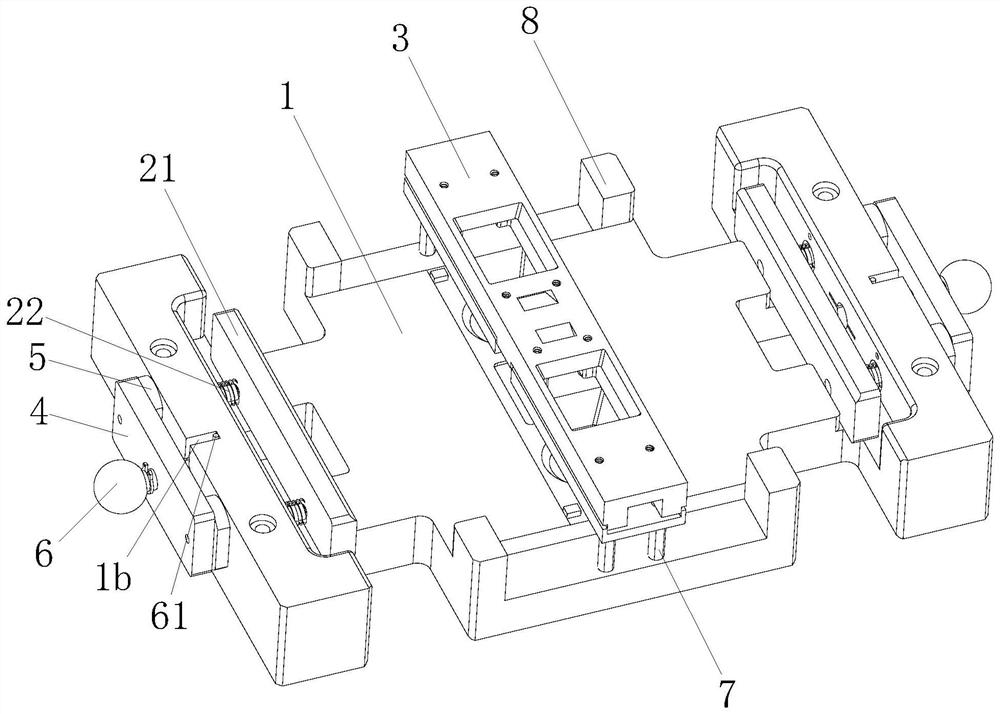

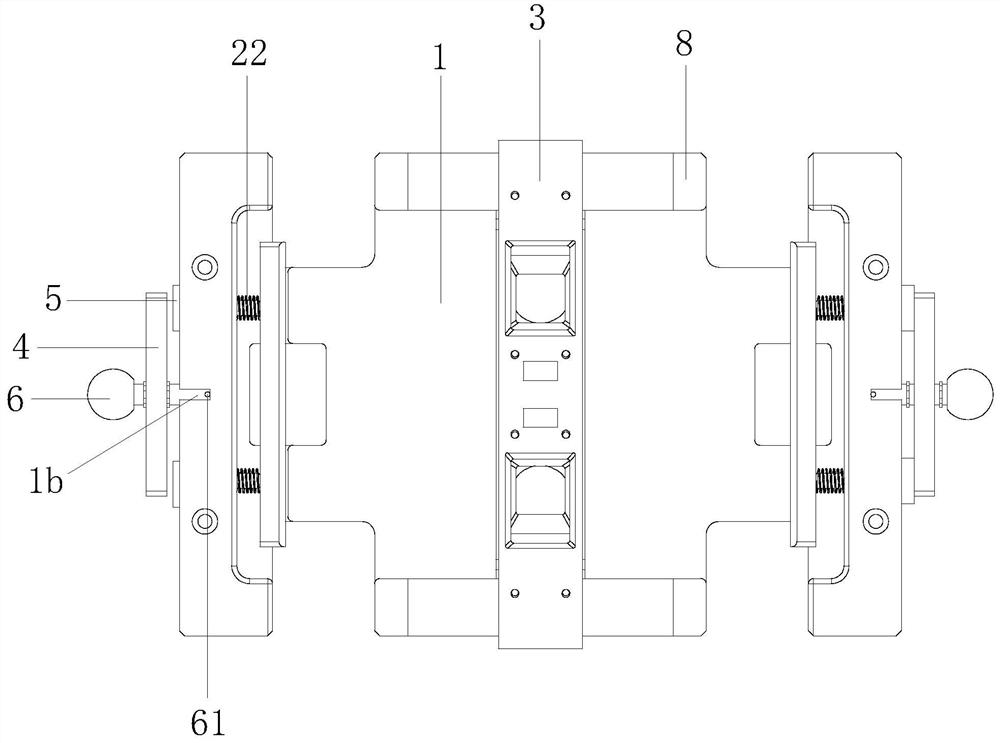

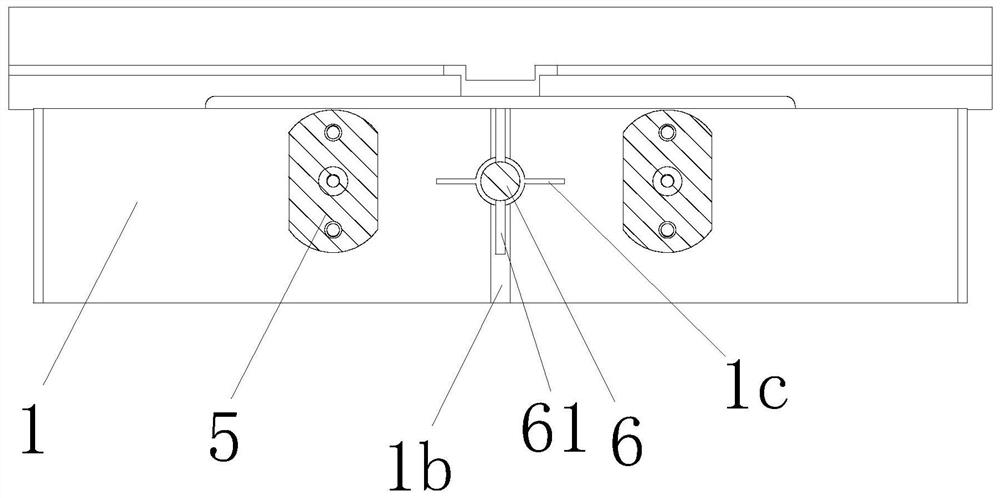

[0029] In order to further understand the content of the present invention, in conjunction with the attached Figure 1-5 And embodiment describe the present invention in detail.

[0030] combined with Figure 1-5 , a new type of butterfly welding device in this embodiment, including a positioning platform 1 for positioning the battery cover plate, dry cell and dry cell connecting piece; a cell position limiting and pre-tightening structure 2 for positioning the dry cell; The pressure head structure is used to position the battery cover plate and the dry cell connecting piece; the cell limit and pre-tightening structure 2 includes a pre-tightening plate 21, a pre-tightening spring 22 and a guide column 23, and the pre-tightening plate 21 is positioned at the position The inner side of the platform 1 can move toward one side to squeeze the dry cell. The pretension spring 22 is sleeved on the guide column 23, and the guide column 23 can move relative to the positioning platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com