Modified thermoplastic starch and preparation method thereof

A thermoplastic starch modification technology, which is applied in the field of modified thermoplastic starch and its preparation, can solve the problems of low strength and easy retrogradation of thermoplastic starch, and achieve the effects of high mixing uniformity, simple steps, and good anti-retrogradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation method of the modified thermoplastic starch of embodiment 1 may further comprise the steps:

[0046] 1) Add cornstarch and hydroxypropyl methylcellulose to a planetary ball mill in a mass-number ratio of 100:2 for dry ball milling. The grinding medium uses zirconia balls at a temperature of 60°C. The revolution speed of the ball mill is 60 rpm, and the rotation speed 120rpm, ball milling time 30min, to obtain refined starch;

[0047] 2) Add the plasticizer to the planetary ball mill equipped with refined starch in step 1) for dry ball milling, wherein the mass / number ratio of the plasticizer to the starch added in step 1) is 10:100, and the grinding medium adopts Zirconia balls, temperature 90°C, ball milling revolution speed 100rpm, rotation speed 200rpm, ball milling time 35min, to obtain plasticized starch;

[0048] 3) adding the basic catalyst, esterifying agent and coupling agent to the planetary ball mill equipped with plasticized starch in step 2...

Embodiment 6

[0058] The preparation method of the modified thermoplastic starch of embodiment 6, comprises the following steps:

[0059] 1) Put cornstarch and cellulose acetate into a planetary ball mill at a ratio of 100:5 by mass to carry out dry ball milling. The grinding medium is ceramic balls, the temperature is 70°C, the revolution speed of the ball mill is 60 rpm, the rotation speed is 110 rpm, and the milling time is 40 min , to obtain refined starch;

[0060] 2) Add the plasticizer to the planetary ball mill equipped with refined starch in step 1) for dry ball milling, wherein the mass / number ratio of the plasticizer to the starch added in step 1) is 5:100, and the grinding medium adopts Ceramic balls, temperature 95°C, ball mill revolution speed 120rpm, rotation speed 220rpm, ball mill time 40min, to obtain plasticized starch;

[0061] 3) adding the basic catalyst, esterifying agent and coupling agent to the planetary ball mill equipped with plasticized starch in step 2) and ca...

Embodiment 11

[0070] The preparation method of the modified thermoplastic starch of embodiment 11, comprises the following steps:

[0071] 1) Put cornstarch and cellulose acetate into a planetary ball mill at a ratio of 100:6 by mass and number for dry ball milling. The grinding medium is zirconia balls at a temperature of 80°C. 30min, obtain refined starch;

[0072] 2) Add the plasticizer to the planetary ball mill equipped with refined starch in step 1) for dry ball milling, wherein the mass / number ratio of the plasticizer to the starch added in step 1) is 15:100, and the grinding medium adopts Zirconia balls, temperature 95°C, ball milling revolution speed 120rpm, rotation speed 210rpm, ball milling time 35min, to obtain plasticized starch;

[0073]3) adding the basic catalyst, esterifying agent and coupling agent to the planetary ball mill equipped with plasticized starch in step 2) and carrying out dry ball milling, wherein the basic catalyst, esterifying agent, coupling agent and ste...

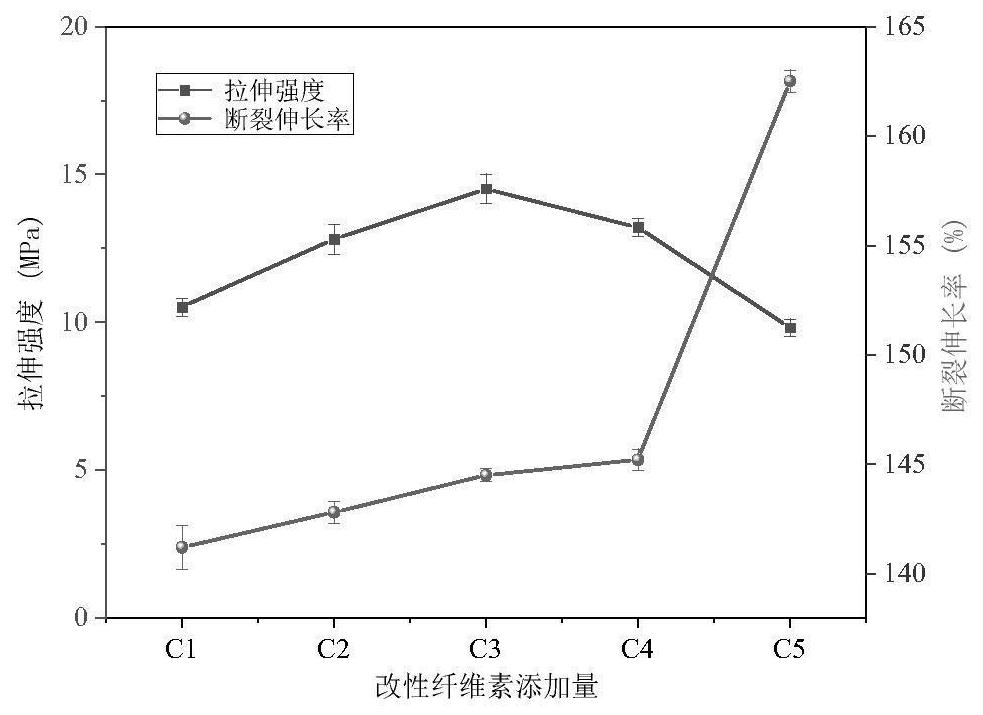

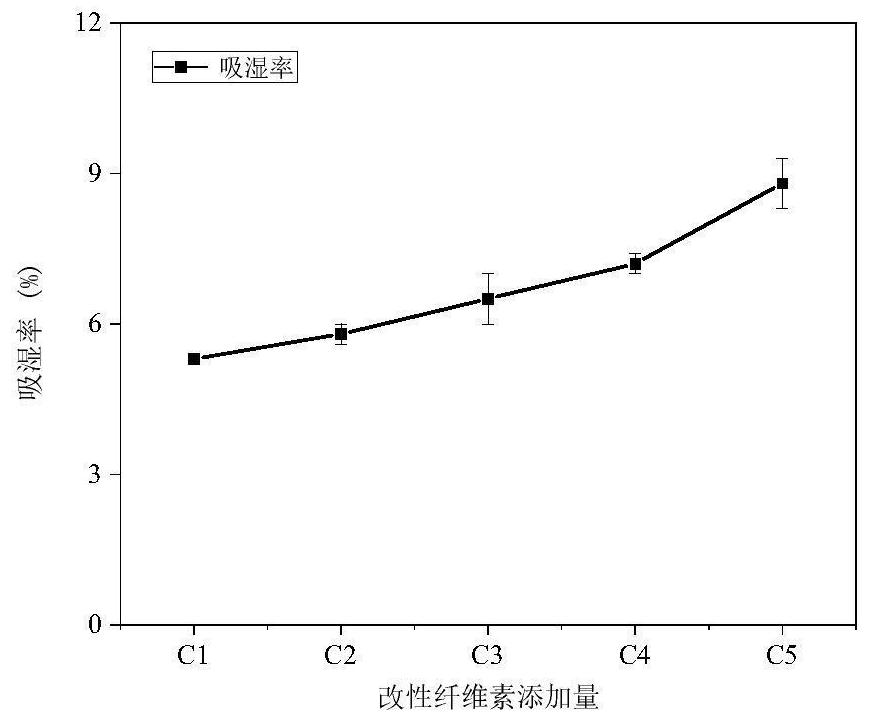

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com