Modified plastic-wood composite material plate and preparation method thereof

A wood-plastic composite material and modification technology, applied in the field of plate preparation, can solve the problems of low static bending strength and easy deformation, and achieve the effects of reduced expansion, reduced water absorption thickness and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

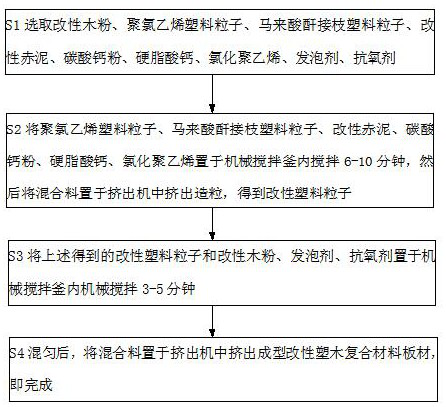

[0020] refer to figure 1 , a modified wood-plastic composite board, prepared from the following raw materials in parts by weight: 100 parts of modified wood powder, 60 parts of polyvinyl chloride plastic particles, 10 parts of maleic anhydride grafted plastic particles, modified red 8 parts of mud, 5 parts of calcium carbonate powder, 3 parts of calcium stearate, 2 parts of chlorinated polyethylene, 0.5 parts of foaming agent, and 0.5 parts of antioxidant.

[0021] In the present invention, the particle size of the modified wood powder is 60 mesh to 100 mesh.

[0022] In the present invention, the maleic anhydride-grafted plastic particles are one of maleic anhydride-grafted polyethylene, maleic anhydride-grafted polypropylene, and maleic anhydride-grafted polystyrene.

[0023] A method for preparing a modified wood-plastic composite board, comprising the following preparation steps:

[0024] S1 selects modified wood flour, polyvinyl chloride plastic particles, maleic anhydr...

Embodiment 2

[0033] refer to figure 1 , a modified wood-plastic composite board, prepared from the following raw materials in parts by weight: 100 parts of modified wood powder, 60 parts of polyvinyl chloride plastic particles, 10 parts of maleic anhydride grafted plastic particles, modified red 8 parts of mud, 7 parts of calcium carbonate powder, 4 parts of calcium stearate, 3 parts of chlorinated polyethylene, 0.5 parts of foaming agent, and 0.5 parts of antioxidant.

[0034] In the present invention, the particle size of the modified wood powder is 60 mesh to 100 mesh.

[0035] In the present invention, the maleic anhydride-grafted plastic particles are one of maleic anhydride-grafted polyethylene, maleic anhydride-grafted polypropylene, and maleic anhydride-grafted polystyrene.

[0036] A method for preparing a modified wood-plastic composite board, comprising the following preparation steps:

[0037] S1 selects modified wood flour, polyvinyl chloride plastic particles, maleic anhydr...

Embodiment 3

[0046] refer to figure 1 , a modified wood-plastic composite board, prepared from the following raw materials in parts by weight: 100 parts of modified wood powder, 60 parts of polyvinyl chloride plastic particles, 10 parts of maleic anhydride grafted plastic particles, modified red 8 parts of mud, 9 parts of calcium carbonate powder, 5 parts of calcium stearate, 5 parts of chlorinated polyethylene, 0.5 parts of foaming agent, and 0.5 parts of antioxidant.

[0047] In the present invention, the particle size of the modified wood powder is 60 mesh to 100 mesh.

[0048] In the present invention, the maleic anhydride-grafted plastic particles are one of maleic anhydride-grafted polyethylene, maleic anhydride-grafted polypropylene, and maleic anhydride-grafted polystyrene.

[0049] A method for preparing a modified wood-plastic composite board, comprising the following preparation steps:

[0050] S1 selects modified wood flour, polyvinyl chloride plastic particles, maleic anhydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com