First twisting, stranding and second twisting all-in-one machine for ceramic fibers

A ceramic fiber, integrated machine technology, applied in textiles, papermaking, yarn and other directions, can solve the problems of twisting defect cohesion, low elongation at break, serious wear of ceramic fibers, etc., to reduce wear and improve the strength of bundles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings and the following embodiments. It should be understood that the drawings and the following embodiments are only used to illustrate the present invention rather than limit the present invention.

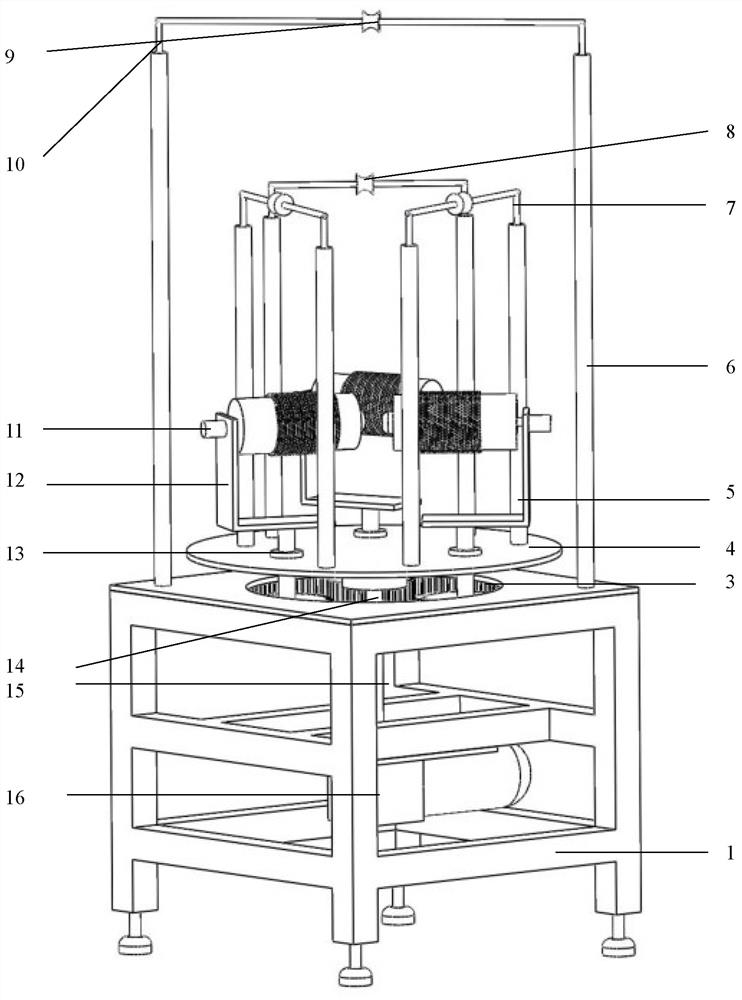

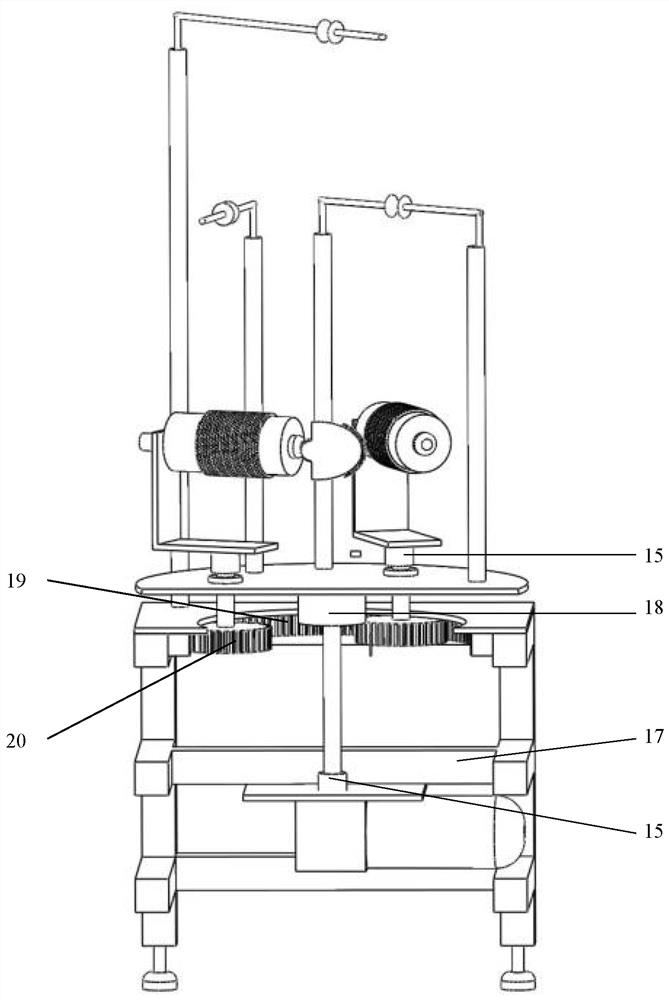

[0019] In view of the shortcomings of the existing ply and twist equipment, such as step-by-step, long process, and large wear on ceramic fibers, a primary twist ply and double twist integrated machine for ceramic fibers is provided, which uses the principle of planetary revolution and rotation to realize primary twist ply and double twist The integrated device includes a main body bracket, a planetary wheel and a sun disc installed on the main body bracket. The wire feeding machine is coaxial with the planetary gear and fixed on the sun disk. The first wire godet corresponding to the wire-drawing machines is arranged above each wire-drawing machine. The second godet wheel is disposed above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com