Waterproof moisture-permeable film and preparation method and application thereof

A technology of waterproof and moisture-permeable membrane and water-repellent agent, applied in textiles and papermaking, non-woven fabrics, fiber types, etc., can solve the problems of poor bonding force and poor durability of hydrophobic coating, and achieve small pore size, high water pressure resistance and permeability. Wet flux, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this example, a waterproof and moisture-permeable membrane is prepared, and the specific steps are as follows:

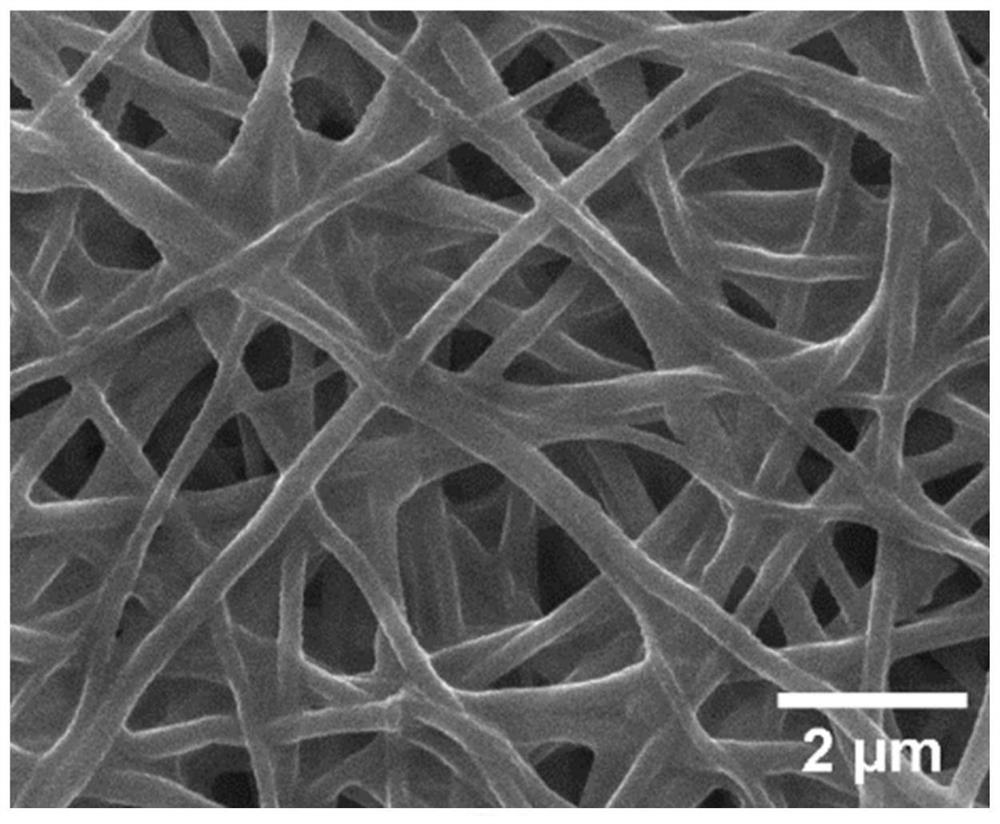

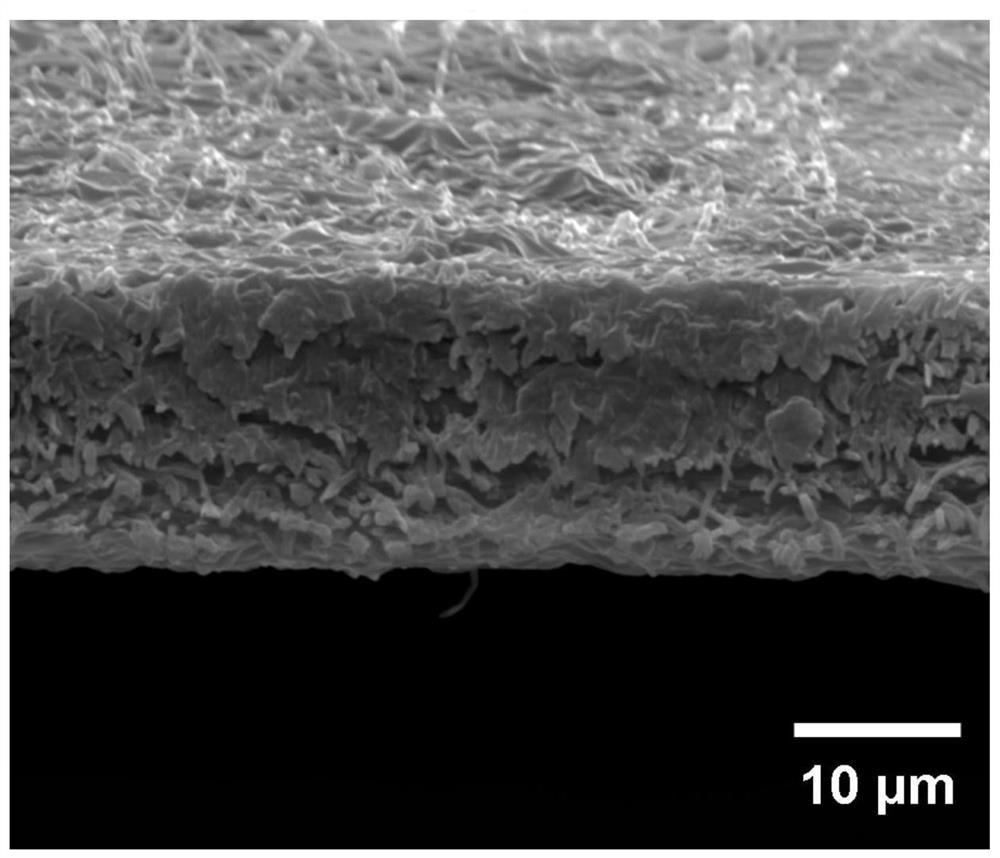

[0041] (1) Preparation of electrospun fiber membrane: Dissolve blocked solvent-based isocyanate (unblocking temperature: 80°C) and polyacrylonitrile (relative molecular mass: 90,000) in solvent N, N- Prepare a spinning solution with a mass fraction of 8wt% in dimethylformamide, mechanically stir to obtain a uniform and stable solution, and receive polyacrylonitrile composite fiber membranes on glossy paper by electrospinning technology. The spinning voltage is 30kV, and the receiving distance The temperature is 20cm, the perfusion rate is 3mL / h, the temperature is 25°C, and the relative humidity is 50%.

[0042] (2) Get 2g of stearic acid solution with a solid content of 25%, prepare a 2wt% stearic acid solution, fully immerse the polyacrylonitrile composite fiber membrane in the stearic acid solution at room temperature, and then After drying for 30 minu...

Embodiment 2

[0047] In this example, a waterproof and moisture-permeable membrane is prepared, and the specific steps are as follows:

[0048] (1) Preparation of electrospun fiber membrane: Dissolve blocked solvent-based isocyanate (unblocking temperature 100°C) and cellulose acetate (acetyl 39.8wt%, hydroxyl 3.5wt%) in a mass ratio of 2:1 Prepare a spinning solution with a mass fraction of 18wt% in solvent dimethyl sulfoxide and acetone, mechanically stir to obtain a uniform and stable solution, and receive a cellulose acetate composite fiber film on glossy paper by electrospinning technology, and the spinning voltage is 30kV, the receiving distance is 20cm, the perfusion rate is 3mL / h, the temperature is 23°C, and the relative humidity is 60%.

[0049] (2) Take 1 g of hydroxy-terminated polysiloxane solution with a solid content of 30%, prepare a 2wt% hydroxy-terminated polysiloxane solution, and fully impregnate the cellulose acetate composite fiber membrane in the hydroxy-terminated po...

Embodiment 3

[0052] In this example, a waterproof and moisture-permeable membrane is prepared, and the specific steps are as follows:

[0053] (1) Preparation of electrospun fiber membrane: Dissolve blocked solvent-based isocyanate (unblocking temperature at 90°C) and nylon 6 (weight-average molecular weight 50,000) in solvent formic acid to prepare a mass ratio of 3:4 The spinning solution with a fraction of 10wt% was mechanically stirred to obtain a uniform and stable solution. The nylon 6 composite fiber membrane was received on glossy paper by electrospinning technology. The spinning voltage was 40kV, the receiving distance was 20cm, and the perfusion speed was 2mL / h , the temperature is 20°C, and the relative humidity is 60%.

[0054] (2) Take 2g of amino-terminated silicone oil solution with a solid content of 25%, prepare a 2wt% amino-terminated silicone oil solution, fully immerse the nylon 6 composite fiber membrane in the amino-terminated silicone oil solution at room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| water pressure | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com