Enzyme-treated cashmere fiber dyeing process

A cashmere fiber and enzyme treatment technology, applied in dyeing, enzyme/microbial biochemical treatment, fiber treatment, etc., can solve the problems of cashmere fiber damage, affecting fiber quality and hand feeling, and different penetration of dyeing solution, etc., to increase Breaking strength and elongation, improving the color fastness of dyeing, improving the effect of fumigation and color fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

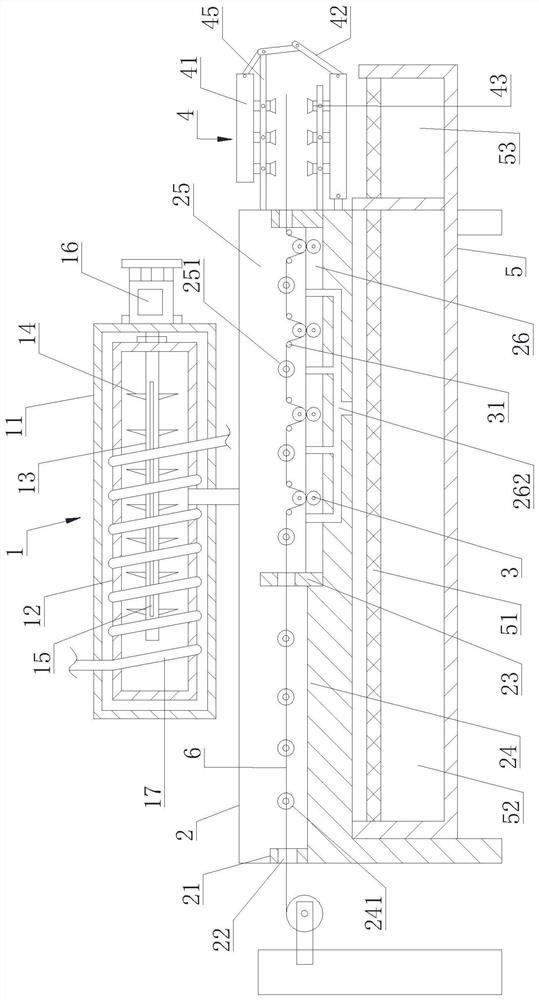

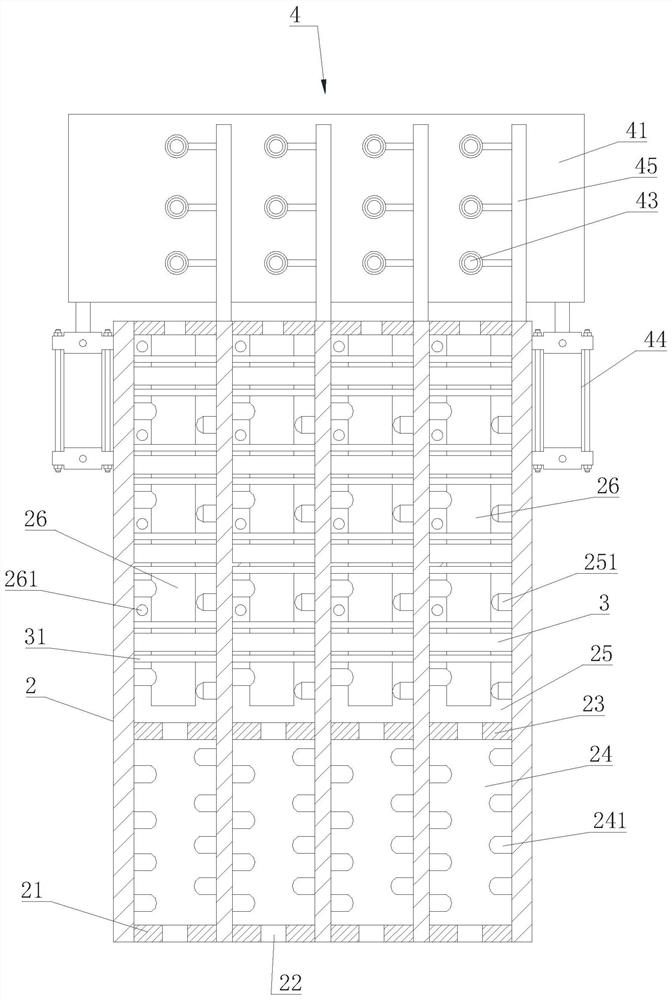

[0030] Such as Figure 1-2 Shown, enzyme treatment cashmere fiber dyeing process comprises the following steps:

[0031] A. Cashmere fiber pretreatment: Immerse the cashmere fiber in the treatment liquid composed of protease, hydrogen peroxide and wool protectant. ~ 10min positive and negative cycle once, and ultrasonic treatment under the condition of 25 ~ 45kHz at the same time, to obtain fiber A;

[0032] B. Prepare the dye liquor: put the low-temperature auxiliary agent, formic acid, reactive dyes and wool protectant into the dye liquor tank and mix, raise the temperature to 50-75°C, and keep stirring for 20-40min to obtain the dye liquor A;

[0033] C. Conveying the dye solution: cool the dye solution A to 30-40°C to obtain the dye solution B, and transport it to the dyeing box;

[0034] D. Hot air treatment: Treat fiber A with hot air at 50-60°C to make it fluffy and obtain fiber B;

[0035] E. Spray dyeing treatment: spray the dye solution B to the fiber B through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com