Material box for titanium and titanium alloy EB smelting

A titanium alloy and material box technology, applied in the field of titanium material processing, can solve the problems of melting stability and composition uniformity, low efficiency of bundling or welding, exceeding the range of electron beam melting, etc. Oblique phenomenon, improved stability and uniformity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

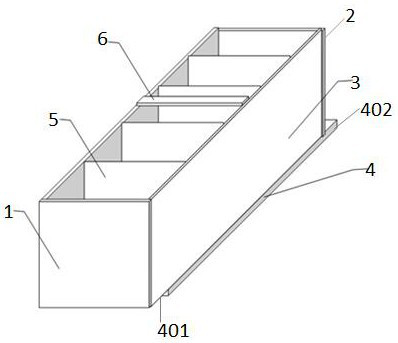

[0026] A method for preparing a titanium and titanium alloy EB smelting bin, comprising the following preparation steps:

[0027] Step 1. Material selection: select pure titanium or titanium alloy plates with a thickness of 3~6mm or corresponding plate residues as plates for the material box, melt different materials, select plates or plate residues of corresponding materials, and select pure titanium plates below 1mm As the internal partition 5 of the material box;

[0028] Step 2, cutting; each material box is divided into 1 front end plate, 1 rear end plate, 1 bottom plate, 2 side plates, 1 tie bar and several partitions, and the plate is cut to be suitable for EB furnace feeding The specifications of the mouth size, in which the width and height dimensions are based on the size of the feed port, and a margin of 20~50mm and 50~150mm is reserved on the basis of the feed port size, and the length of the material box is greater than 1500mm;

[0029] Step 3. Tailor welding; Ta...

Embodiment 1

[0036] Melting TA2 material slab: select TA2 plate with a thickness of 3mm, and a part of 3~4mm plate residue as the plate for the material box, and select 0.5mm TA2 titanium plate as the inner partition of the material box.

[0037] Each material box has 1 front end plate, 1 rear end plate, 1 bottom plate, 2 side plates, 1 tie bar and 4 partitions. The size of the front and rear end plates is 450×450mm, and the bottom plate is 450×1600mm. The side plate is 450×1600mm, the lacing rib is 300×450mm, and the deviation is ±5mm. Splice the board remnants to the above specifications. 41 sets of box boards are cut.

[0038] according to figure 1bin shown. The bottom plate protrudes 40mm in length towards one end, that is, the length of the pressing plate is 40mm. The bottom of the upright side plate is located on the top of the bottom plate, and the TA2 welding wire is used for argon shielded welding. The front end plate of the head of the material box is fully welded to the side...

Embodiment 2

[0042] Melting TC4 material slab: select TC4 plate with a thickness of 6mm, and a part of 4~6mm plate residue as the plate for the material box.

[0043] Each material box has 1 front panel, 1 rear panel, 1 bottom panel, 2 side panels and 1 tie bar. The size of the front and rear panels is 450×480mm, the bottom panel is 450×1550mm, and the side panel is 480×1550mm. , Stretch 300×450mm, the deviation is ± 5mm. Splice the board remnants to the above specifications. 34 sets of box board cutting.

[0044] according to figure 1 bin shown. The bottom plate protrudes 100mm in length towards one end, that is, the length of the pressing plate is 100mm. The bottom of the upright side plate is located on the top of the bottom plate, and TC4 welding wire is used for argon shielded welding. The front end plate of the head of the bin is fully welded to the side plate, the rear end plate of the tail is connected to the side plate for half welding, and the bottom plate is connected to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com