circuit board

A technology of circuit board and circuit layout, applied in the direction of circuit, printed circuit, printed circuit, etc., can solve problems such as bump bridge short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

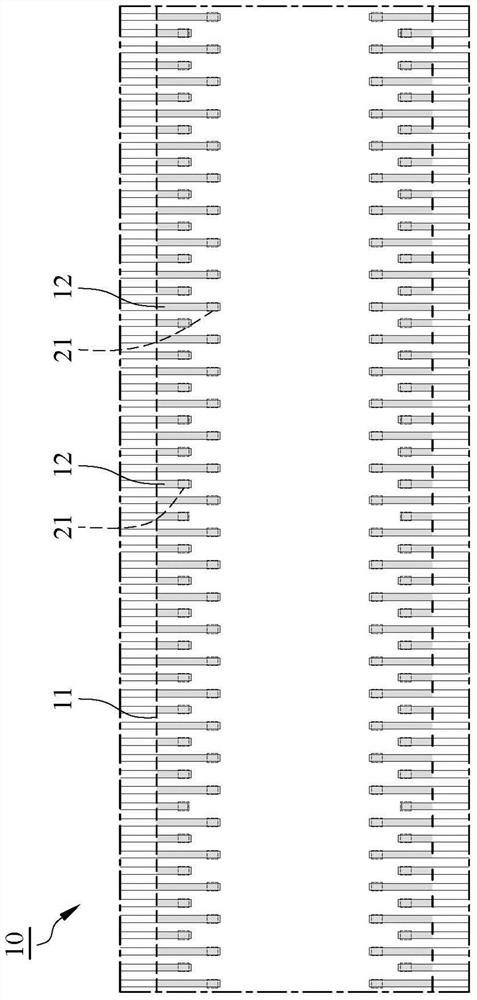

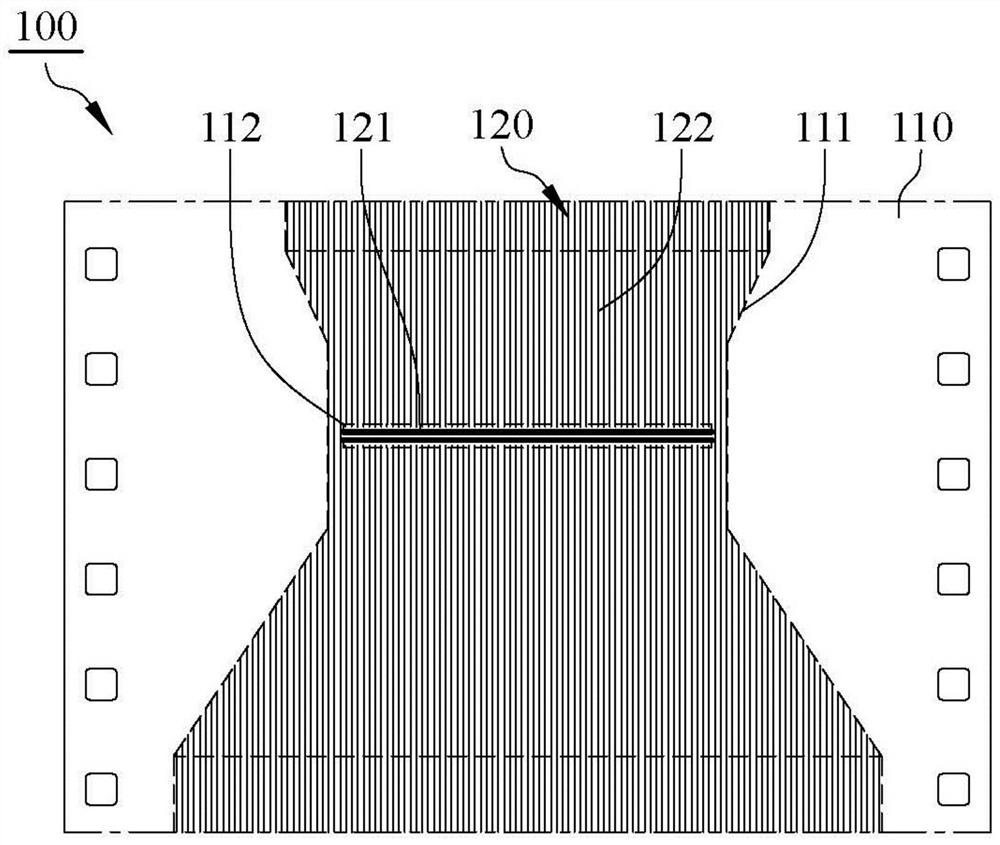

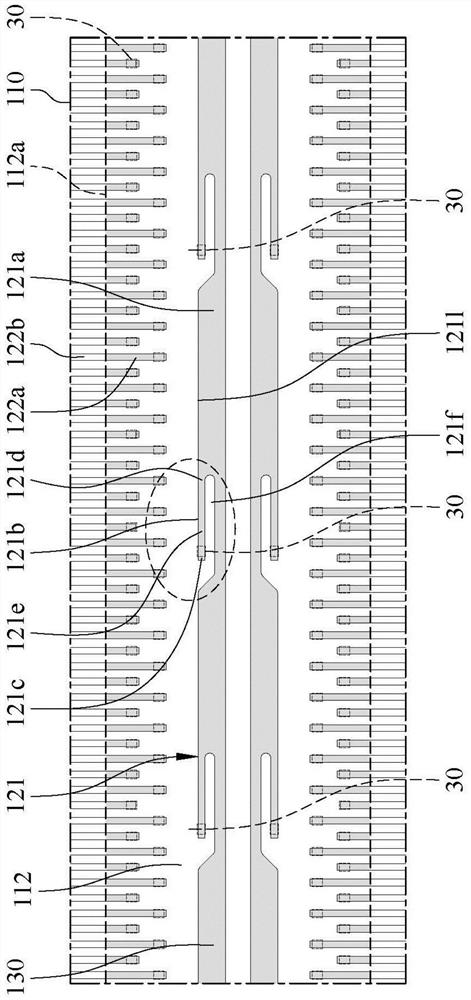

[0043] see figure 2 , image 3 and Figure 4 , the first embodiment of a circuit board 100 of the present invention, the circuit board 100 includes a substrate 110 and a circuit layer 120, preferably, the circuit board 100 further includes a solder layer 130, the solder layer 130 covers the circuit layer 120 , and the thickness of the solder layer 130 is not more than 0.3 μm, please refer to figure 2 , the substrate 110 has a circuit layout area 111 and a chip setting area 112, the chip setting area 112 is used for setting chips (not shown in the figure), and the chip setting area 112 is the bump setting area of the chip projected onto the substrate 110 The bump setting area is provided with a plurality of bumps 30 .

[0044] see figure 2 , image 3 and Figure 4 , the circuit layer 120 has at least one first circuit 121 and a plurality of second circuits 122, each of the second circuits 122 includes an inner pin 122a and a base line 122b, the base line 122b is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com