Selective laser melting processing method and application of high nickel-rich niti alloy

A technology of laser melting and processing methods, which is applied in the field of shape memory alloys, can solve problems such as the inability to apply NiTi alloys with high nickel content, difficulty in preparing structural parts, and difficulty in molding, and achieve excellent compression fracture strength, high molding accuracy, and few internal defects. Effect

Active Publication Date: 2022-05-31

CHINA UNIV OF PETROLEUM (BEIJING)

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] At present, there have been many reports on the research results of near-equal atomic ratio NiTi alloys prepared by SLM, but the method of preparing near-equal atomic ratio NiTi alloys by SLM cannot be applied to NiTi alloys with high nickel content.

This is because, unlike NiTi alloys with near equiatomic ratio, NiTi alloys with high nickel content are essentially a kind of Ni 4 Ti 3 NiTi-Ni with a ceramic phase ratio of more than 40% 4 Ti 3 Composite materials, whose microstructure, mechanical properties and phase transition behavior are significantly different from those of near equiatomic ratio NiTi alloys, are extremely difficult to form, and it is even more difficult to prepare structural parts with complex shapes

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

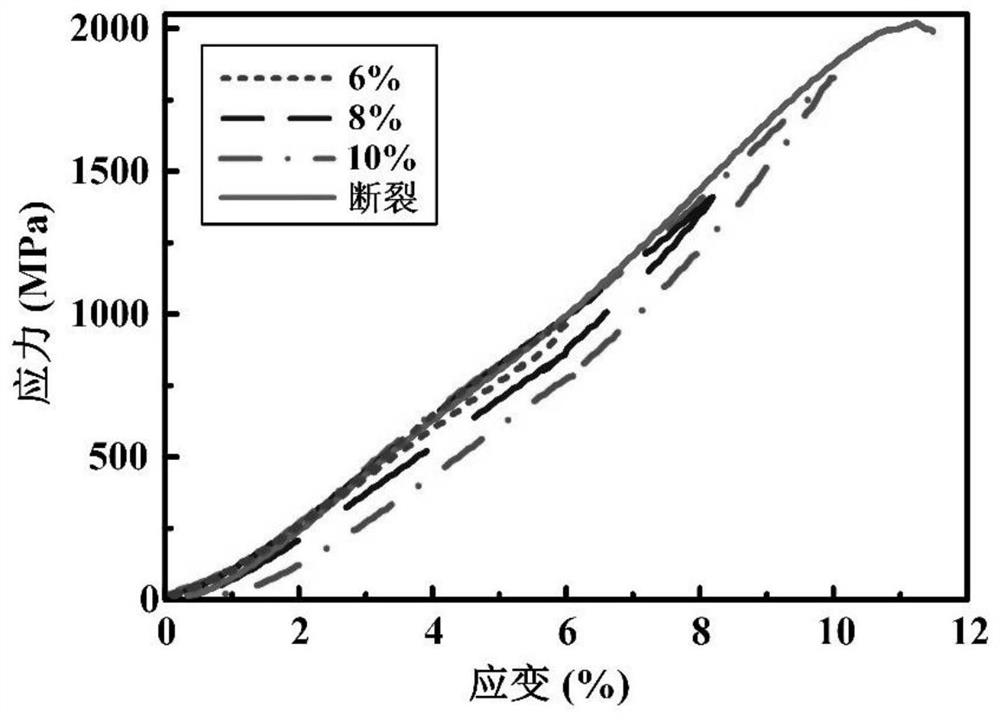

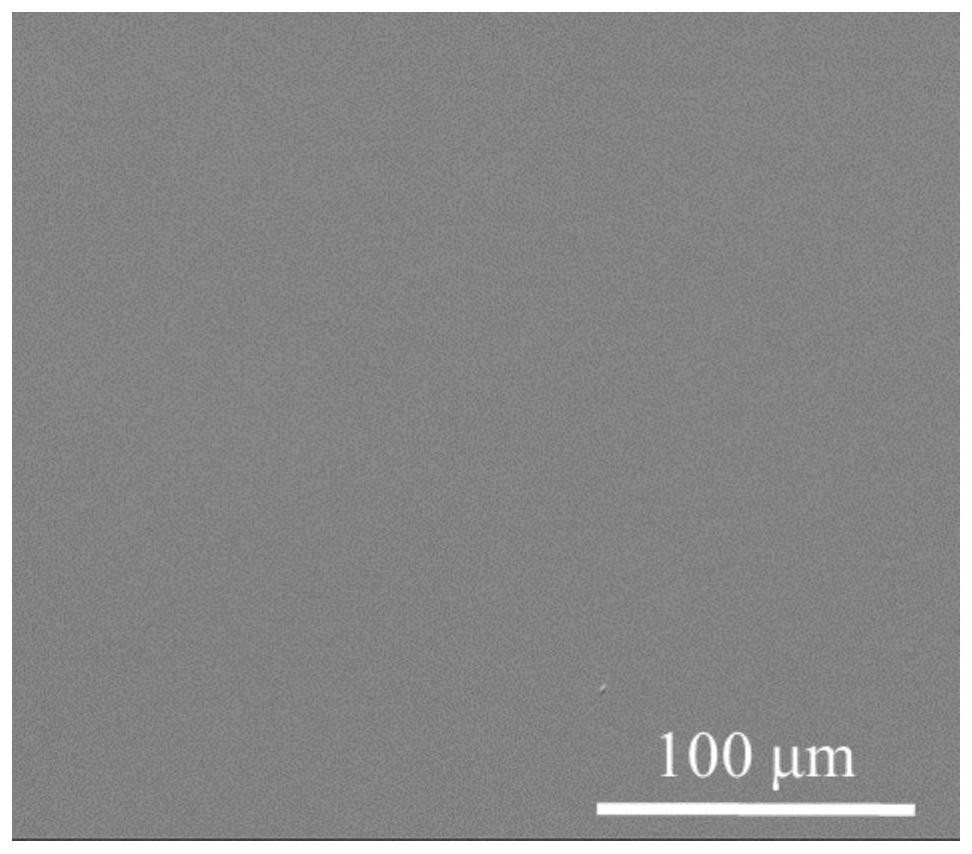

[0070] As can be seen from Figure 3: the high nickel content NiTi alloy sample has no obvious defects, and the molding quality is better. and tested

Embodiment 2

[0081] As can be seen from Figure 5: the high nickel content NiTi alloy sample has no obvious defects, and the molding quality is better. and tested

Embodiment 3

[0088] Wherein, the laser power is 140W, the spot diameter is 70 μm, the scanning speed is 400 mm / s, and the scanning distance is 50 μm,

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a selective laser melting processing method and application of high nickel-rich NiTi alloy. The processing method includes: 1) presetting NiTi alloy powder to form a layer to be treated, in which the atomic percentage of Ni element is 53-57%, and the balance is Ti atoms; 2) according to the printing process parameters, the The layer to be treated is subjected to laser melting treatment to form the target layer; 3) Step 1)-step 2) is repeated to form a NiTi alloy piece; in the laser melting treatment, the laser power is 80-150W, and the laser scanning speed is 150-450mm / s, the laser scanning distance is 30‑120 μm. The processing method can perform selective laser melting processing on the NiTi alloy powder with high nickel content, which not only can ensure the precision of the processed part, but also can make the processed part have excellent performance in terms of mechanical properties.

Description

Selective laser melting processing method and application of high nickel-rich NiTi alloy technical field The present invention relates to a kind of processing method of high nickel-rich NiTi alloy, relate in particular to a kind of selection of high nickel-rich NiTi alloy A selective laser melting processing method and application belong to the technical field of shape memory alloys. Background technique [0002] Nickel-titanium binary alloys with high nickel content (such as 53–57 at.% Ni) have high hardness, low density, and excellent corrosion resistance It has the advantages of corrosion resistance and superelasticity, which is very beneficial for structural applications, and has potential applications in aerospace, deep-sea exploration and other fields. force. However, the machinability of NiTi alloys with high nickel content is extremely poor, there are difficulties in chip removal, poor weldability and superelasticity inducers. Problems such as poor machining a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B22F10/28B33Y10/00B33Y70/00B33Y80/00C22C19/03

CPCB33Y10/00B33Y70/00B33Y80/00C22C19/03Y02P10/25

Inventor 郝世杰沈慧杨英郭方敏崔清丽

Owner CHINA UNIV OF PETROLEUM (BEIJING)

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com