Selective laser melting machining method and application of high-nickel-rich NiTi alloy

A laser melting and processing method technology, applied in the field of shape memory alloys, can solve the problems of inability to apply high nickel content NiTi alloys, difficult to prepare structural parts, difficult forming, etc., and achieve excellent compressive fracture strength, high forming accuracy, and fewer internal defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

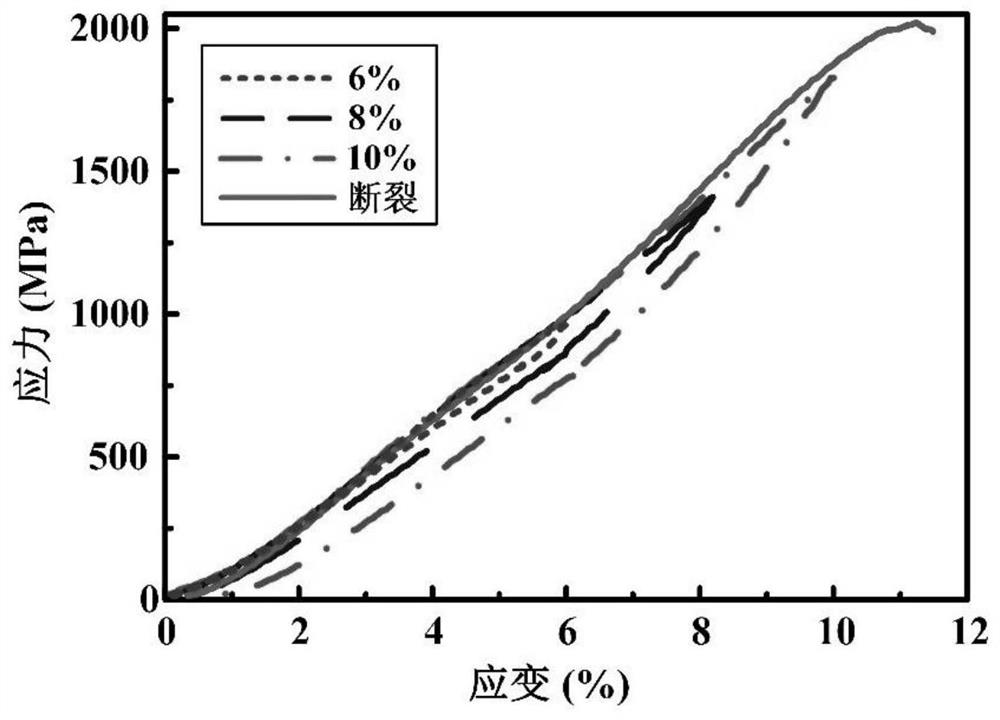

[0061] The selective laser melting processing method of the NiTi alloy of the present embodiment comprises the following steps:

[0062] 1) put the alloy powder whose nickel-titanium atomic ratio is Ni: 53% and Ti: 47%, particle size is 13-65 μm, and D90 is 63.6 μm in a vacuum drying oven at 80° C. for 4 hours;

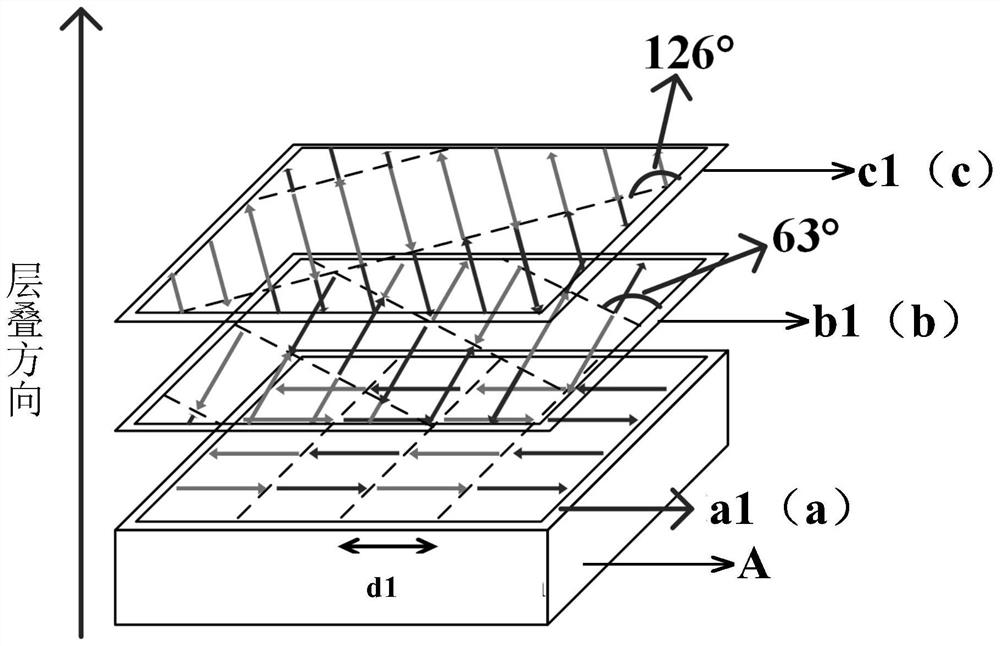

[0063] 2) Construct a three-dimensional model of a 10×10×6mm square sample, then slice it and determine the printing process parameters and input it into the SLM machine processing control system;

[0064] 3) Install the nickel-titanium substrate in the molding cavity and preheat it to 180°C, put the powder dried in step 1) into the powder tank and pre-set evenly on the nickel-titanium substrate to form the first layer to be treated, and then pour the Argon gas is introduced into the molding cavity to make the oxygen content in the molding cavity lower than 500ppm;

[0065] 4) According to the first printing process parameters in the printing process parameters, lase...

Embodiment 2

[0072] The selective laser melting processing method of the NiTi alloy of the present embodiment comprises the following steps:

[0073] 1) put the alloy powder whose nickel-titanium atomic ratio is Ni:55% and Ti:45%, particle size is 13-53 μm, and D90 is 50.9 μm in a vacuum drying oven at 80° C. for 4 hours;

[0074] 2) Construct a three-dimensional model of a 10×10×6mm square sample, then slice it and determine the printing process parameters and input it into the SLM machine processing control system;

[0075] 3) Install the nickel-titanium substrate in the molding cavity and preheat it to 180°C, put the powder dried in step 1) into the powder tank and pre-set evenly on the nickel-titanium substrate to form the first layer to be treated, and then pour the Argon gas is introduced into the molding cavity to make the oxygen content in the molding cavity lower than 500ppm;

[0076] 4) According to the first printing process parameters in the printing process parameters, laser ...

Embodiment 3

[0083] The selective laser melting processing method of the NiTi alloy of the present embodiment comprises the following steps:

[0084] 1) put the alloy powder whose nickel-titanium atomic ratio is Ni: 53% and Ti: 47%, particle size is 13-65 μm, and D90 is 63.6 μm in a vacuum drying oven at 80° C. for 4 hours;

[0085] 2) Construct a three-dimensional model of a 10×10×6mm square sample, then slice it and determine the printing process parameters and input it into the SLM machine processing control system;

[0086] 3) Install the nickel-titanium substrate in the molding cavity and preheat it to 180°C, put the powder dried in step 1) into the powder tank and pre-set evenly on the nickel-titanium substrate to form the first layer to be treated, and then pour the Argon gas is introduced into the molding cavity to make the oxygen content in the molding cavity lower than 500ppm;

[0087] 4) According to the first printing process parameters in the printing process parameters, lase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com