Large kitchen waste heat recovery multi-element utilization device

A waste heat recovery and kitchen technology, which is applied in the direction of steam generation method using heat carrier, indirect heat exchanger, heat exchanger type, etc., can solve the problems of inability to meet various types of heat demand in the kitchen, and single utilization form of waste heat resources in the kitchen , to achieve the effect of compact structure, centralized utilization of heat, and reduction of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

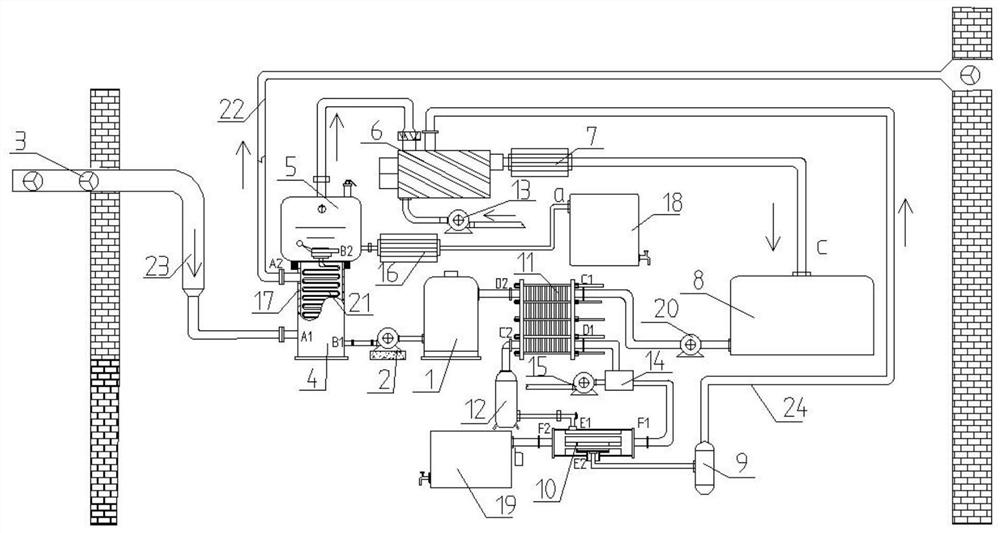

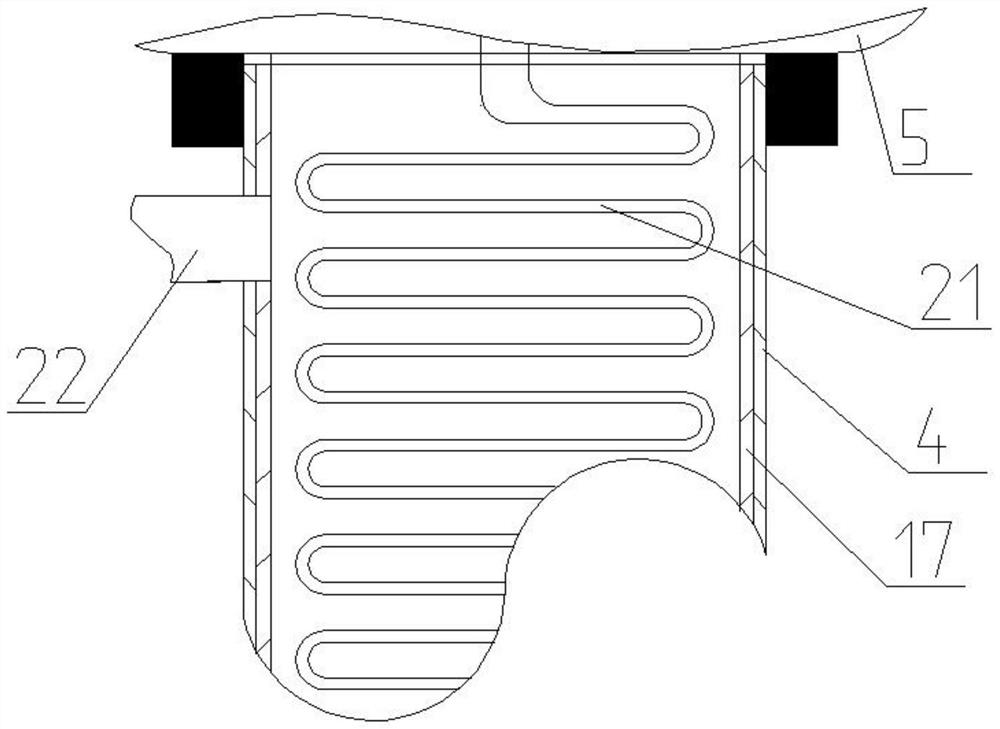

[0028] Example 1, such as Figures 1 to 2 As shown, the present invention is a large-scale kitchen waste heat recovery multiple utilization device, including a heat exchanger 4 connected to the air outlet of the range hood, and the heat exchanger 4 is also connected with a water collection bucket 1, an exhaust pipe 22 and a flash evaporator 5, The steam outlet on the top of the flash evaporator 5 is connected to the steam utilization device 8, the bottom of the flash evaporator 5 is connected to a warm water tank 18, the waste water discharge pipe of the steam utilization device 8 is connected to a heat exchanger 2 11, and the heat exchanger 2 11 is connected to the water collection bucket 1 And the liquid storage tank 12, the liquid storage tank 12 is connected with the economizer 10, and the economizer 10 is connected with the cold water tank 19.

[0029] The heat exchanger-4 is provided with a heat exchange coil 21, one end of the heat exchange coil 21 is connected to the c...

Embodiment 2

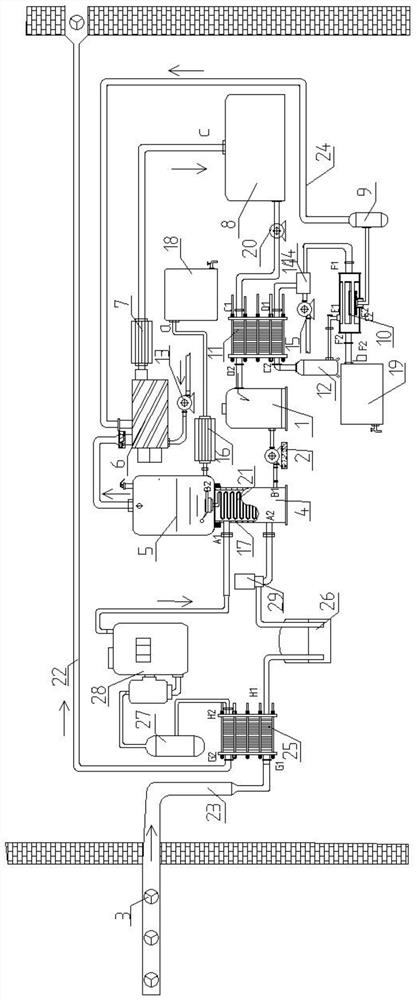

[0044] Embodiment 2 is different from Embodiment 1 in that the outlet of the heat exchanger 4 is connected to the expansion valve 29, the expansion valve 29 is connected to the liquid storage tank 26, the liquid storage tank 26 is connected to the evaporator 25, and the refrigerant in the evaporator 25 The outlet is connected to the gas-liquid separator 27, the gas-liquid separator 27 is connected to a refrigerant compressor 28, the outlet of the refrigerant compressor 28 is connected to the inlet of the heat exchanger-4, the air inlet of the evaporator 25 is connected to the air inlet pipe 23, and the evaporator The air outlet of 25 is connected with the exhaust pipe 22, and the inner wall of the heat exchange pipe where the evaporator 25 communicates with the exhaust pipe 22 is coated with a non-stick coating.

[0045] In summary, the present invention uses the refrigerant to absorb the heat of the hot air discharged from the range hood through the evaporator. After absorbing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com