Hot cutting machine for special-shaped valve port of plastic woven bag

A plastic woven bag, hot cutting machine technology, applied in bag making, plastic recycling, paper/cardboard containers, etc., can solve problems such as poor hot cutting effect, constant replacement of special-shaped valve ports, and folds of plastic woven bags. Achieving the effect of convenience, increased tension, and convenience and eagerness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

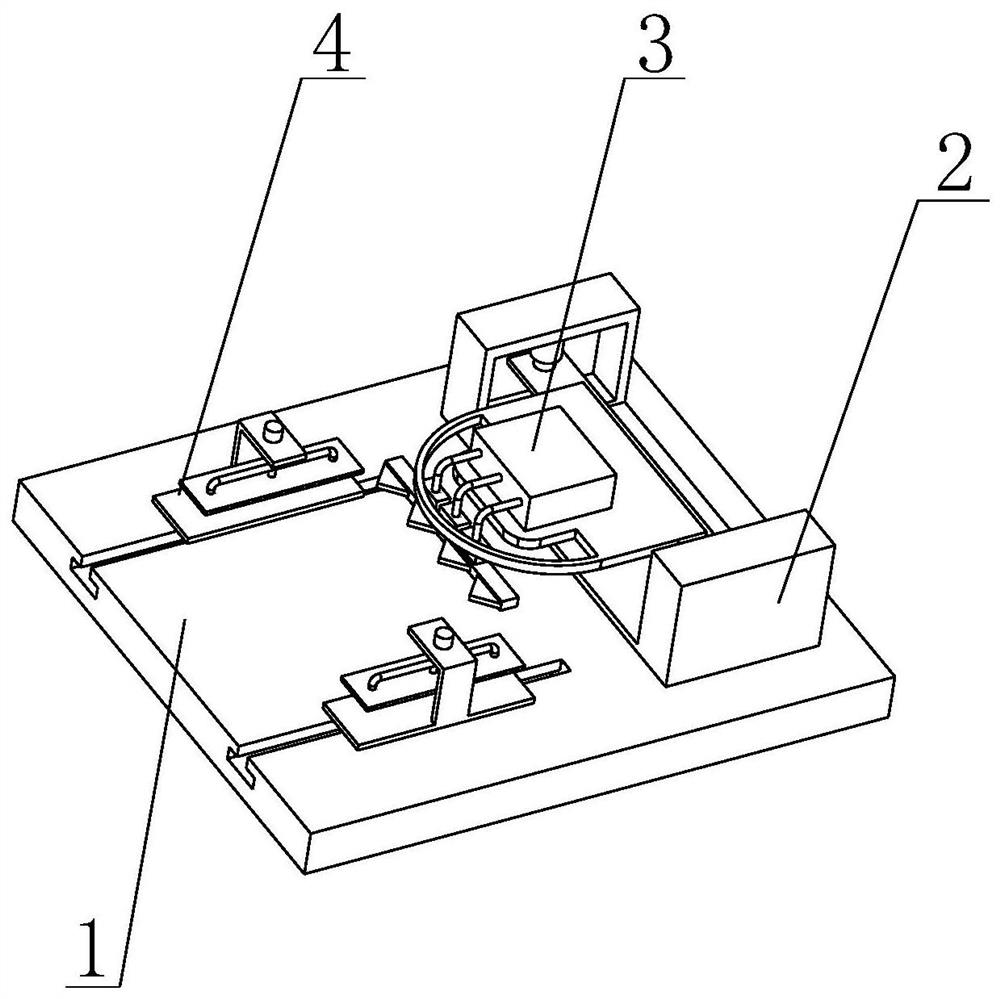

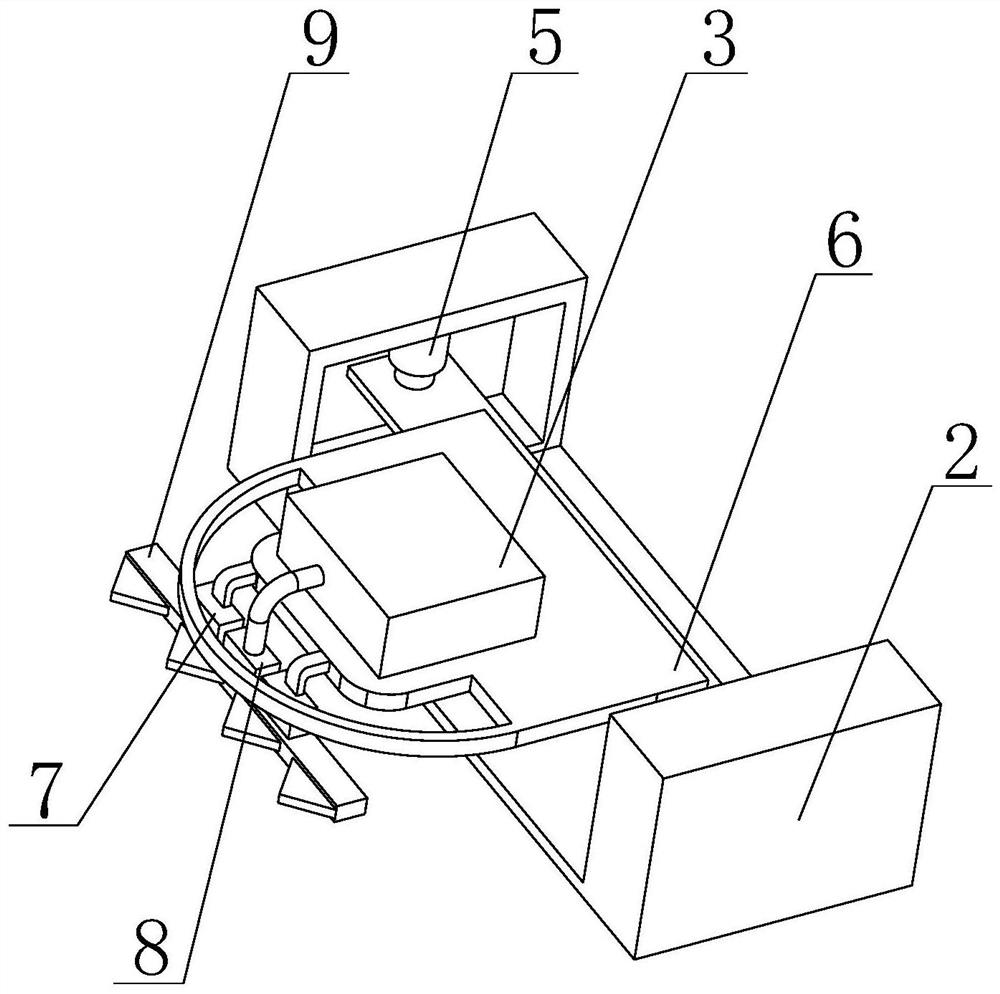

[0033] Such as Figure 1-6 As shown, the present invention provides a plastic woven bag special-shaped valve outlet hot cutting machine, including a cutting body 1, a hot cutting support frame 2, a heating assembly 3 and a plastic woven bag fixing device 4, the top of the cutting body 1 and the hot cutting support frame 2 The bottom is fixedly connected, the bottom of the plastic woven bag fixing device 4 is threadedly connected with the top of the cutting body 1, the inner side wall of the eager support frame 2 is fixedly installed with a lifting mechanism 5, and the lifting end of the lifting mechanism 5 is fixedly connected with a supporting pallet 6, carrying The heating assembly 3 is fixedly installed on the top of the pallet 6, and the lifting mechanism 5 will drive the movement of the supporting pallet 6 and the heating assembly 3 during the lifting process, and the lower left side of the heating assembly 3 is provided with a cutting plate 9. When the supporting pallet ...

Embodiment 2

[0036] Such as Figure 1-6 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, the plastic woven bag fixing device 4 includes a telescopic assembly 14 and an extrusion contact plate 18, and the outer wall of the telescopic assembly 14 and the plastic woven bag fixing device The top of 4 is fixedly connected, and the bottom of the telescopic assembly 14 is fixedly connected with a stamping rod 15. The bottom of the telescopic assembly 14 is provided with a multi-cavity guide tube 16, and the bottom of the multi-cavity guide tube 16 is scattered with a plurality of branch pipes. The stamping rod 15 The outer wall of the multi-lumen guide tube 16 is embedded and connected, and the telescopic assembly 14 can push the movement of the stamping rod 15, so that the stamping rod 15 enters the inside of the multi-lumen guide tube 16 to change the inner wall of the multi-lumen guide tube 16. The size of the air pressure, the top of the ex...

Embodiment 3

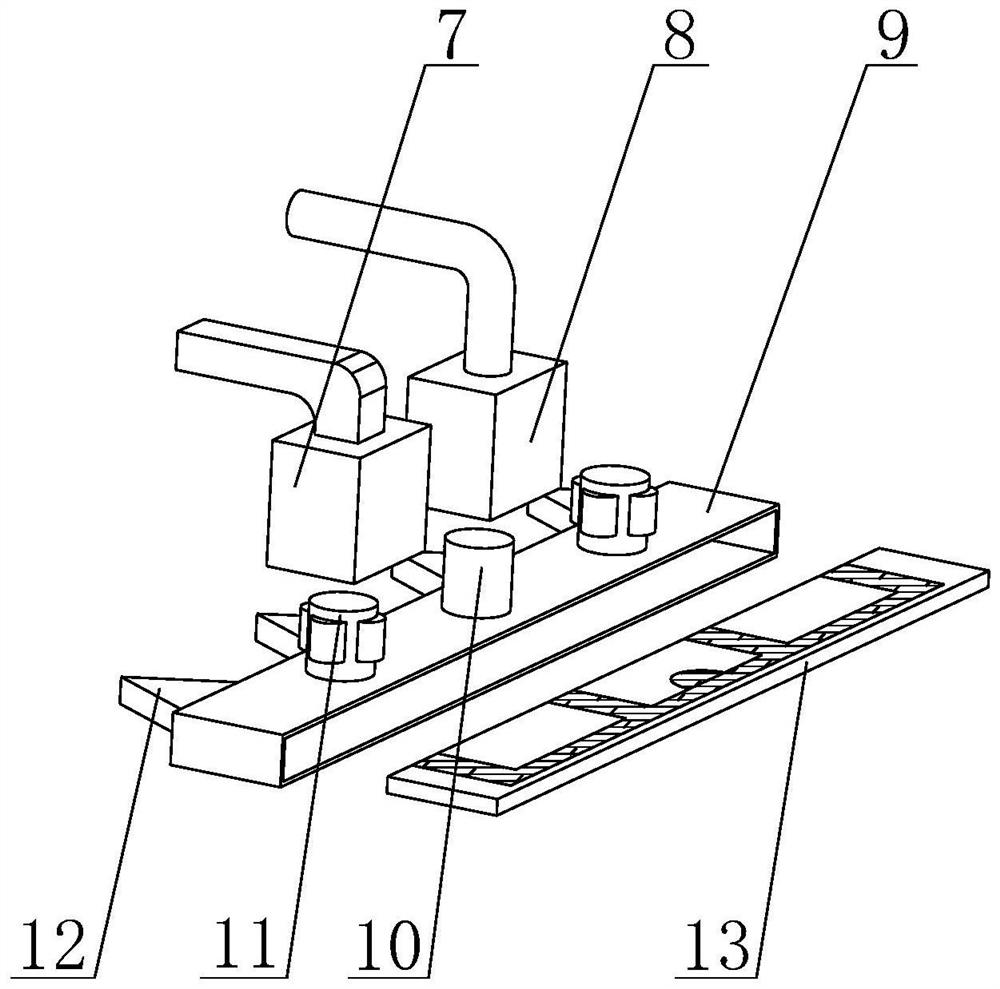

[0038] Such as Figure 1-6As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the outer wall of the clamping device 11 is sleeved with a clamping block 7, and the top of the clamping block 7 is fixedly installed with a T-shaped corner piece, The clamping block 7 is fixedly connected with the outer wall of the supporting pallet 6 through the T-shaped corner piece provided, and the clamping block 7 can install the cutting plate 9 on the supporting pallet 6, and the inner wall of the clamping block 7 is fixedly equipped with magnetic adsorption Block 21, the inner wall of the magnetic adsorption block 21 fits with the outer wall of the arc-shaped magnetic block 20, and the magnetic adsorption block 21 is arranged in a ring at the inner wall axis of the clamping block 7, and the arc-shaped magnetic block 20 and magnetic adsorption There is a certain magnetic adsorption force between the blocks 21. When the clamping device 11 and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap