[0002]

Oxygen cylinders are frequently used and very important

medical equipment in hospitals. They are mainly used for respiratory diseases caused by hypoxia (such as

asthma,

bronchitis,

pulmonary heart disease, etc.), heart and cerebrovascular diseases (such as:

Coronary heart disease,

myocardial infarction, cerebral hemorrhage,

cerebral infarction) to relieve the symptoms of hypoxia; it can also be used for health care

oxygen inhalation or rapid relief of fatigue after intense mental work and

physical work, etc.; oxygen cylinders are generally erected during

oxygen delivery In the ward, because the oxygen cylinder is thin and tall, its stability is poor. If it is accidentally touched, it is easy to fall over. Once it falls over, the patient will be very dangerous. Moreover, the oxygen cylinder is heavy and needs to be moved out and replaced with a new one after use.

Oxygen bottle, the body of the bottle is a smooth cylinder, there is no

stress point, and it is not easy to carry

[0003] Oxygen cylinders are high-pressure containers for storing and transporting oxygen. Generally, they are cylindrical airtight cylinders made of

alloy structural steel by

stamping and

welding. After the cylinder is filled with high-pressure oxygen, the overall weight is relatively large, and it can be moved by two people at short distances. The staff lifts up and moves, but it is more dangerous and poses a greater

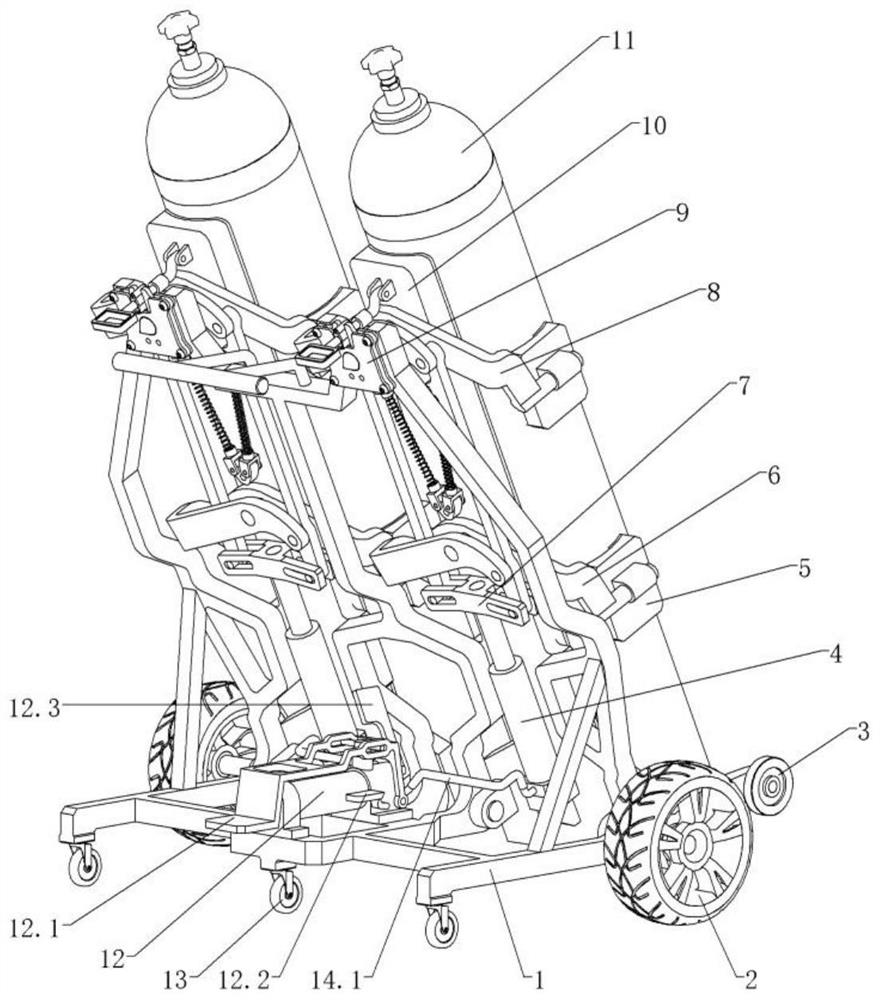

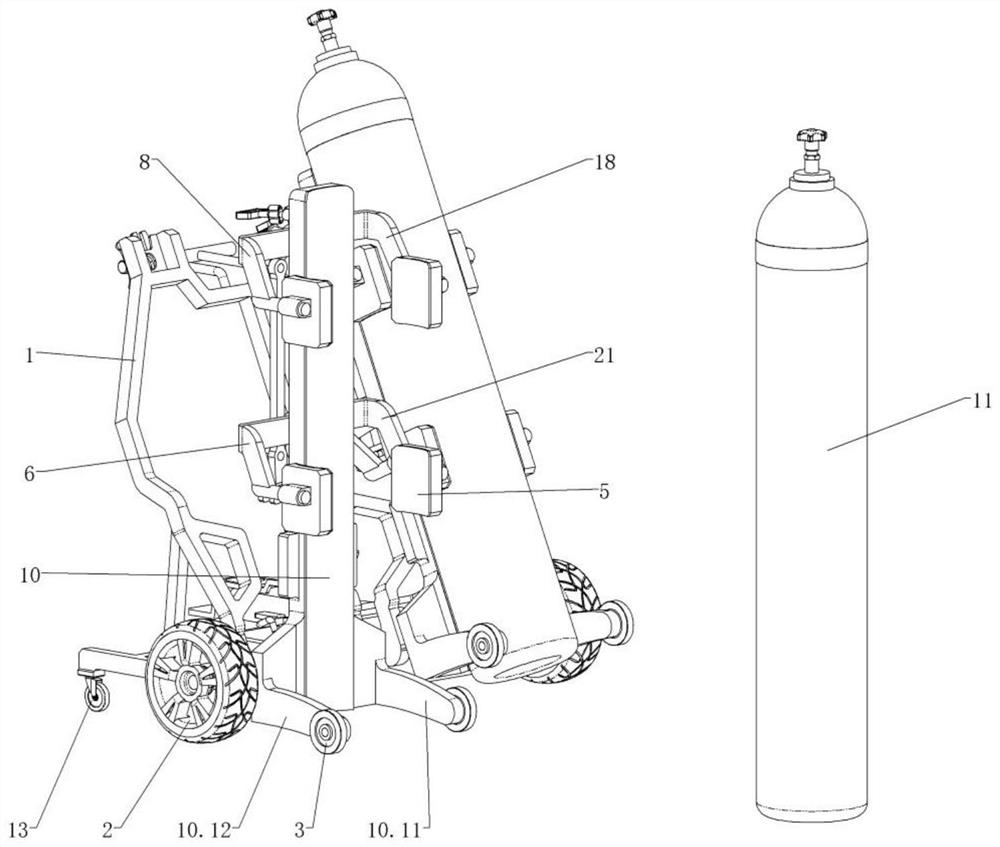

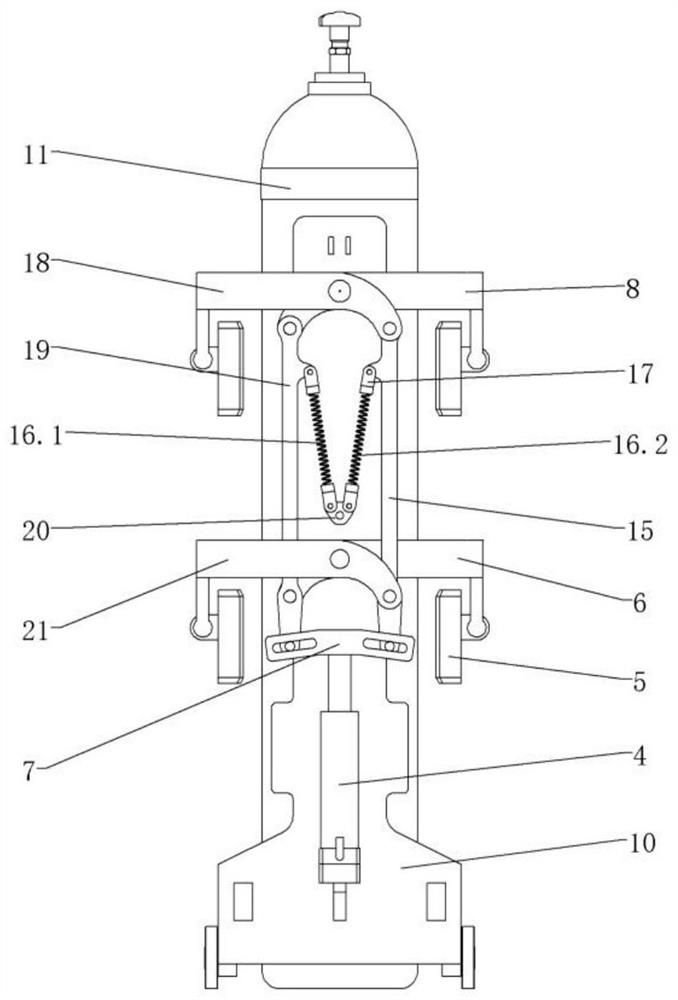

threat to the personal safety of surrounding personnel; longer-distance transportation will be realized by oxygen cylinder trucks, which usually include slender vehicles The lower end of the car body has a supporting plate, and the lower part of the car body is provided with rollers. When carrying the oxygen cylinder, adjust the car body to a vertical state. One worker lifts the bottom side of the oxygen cylinder off the ground first, and the other Personnel push the car body so that the supporting plate extends between the bottom surface of the oxygen cylinder and the ground, then release the oxygen cylinder, the bottom of the oxygen cylinder is located on the supporting plate, and fix the tank body on the main body of the

truck with straps Then pull the upper end of the car body backward to make the car body tilt backward, and finally push the car body to transfer the oxygen cylinder. This method requires the cooperation of two people to complete, and it is time-consuming and laborious, and the efficiency is low

[0004] The invention patent with the publication number CN107600130A discloses a medical oxygen cylinder carrier. In order to make the push plate push the oxygen cylinder forward, it is necessary to press the supporting plate against the ground and tilt the body of the carrier forward, so that it can be driven by a

bevel gear. The transmission of the rod pushes the push plate forward. After the push plate pushes the oxygen cylinder to tilt forward and creates a gap with the ground, it pushes the

truck body forward, inserts the supporting plate into the lower side of the oxygen cylinder, and tilts the

truck body backward, thus Complete the loading of the oxygen cylinder, but it has the following defects technically: ①The oxygen cylinder is a slender cylinder, and when the push plate pushes the oxygen cylinder to tilt forward, it is easy to make the center of gravity of the oxygen cylinder move forward and exceed the range of the bottom of the cylinder, thus If the oxygen cylinder is driven forward by the protective belt, it will not only easily injure the personnel, but also the high-pressure oxygen in the cylinder may explode due to a large vibration, resulting in a greater safety accident; ②The floor of the ward is usually brushed Waterproof and non-slip

coating, and when the truck body is pushed forward, the supporting plate is always pressed against the ground, which will not only scratch the ground

coating, but also generate

scratching noise, which is detrimental to the

recovery of the patient; ③The structure is unreasonable, Only by tilting the truck body forward can the push plate extend forward and push the oxygen cylinder to tilt forward. When the

pallet is about to be inserted into the lower end of the oxygen cylinder, if the oxygen cylinder has not tilted forward, the

pallet cannot be inserted into the lower end of the oxygen cylinder; If the oxygen cylinder has been tilted forward, continue to move forward to insert the support plate into the lower end of the oxygen cylinder, the oxygen cylinder will continue to tilt forward, so that the oxygen cylinder will fall forward, causing a safety accident. Such a structure is unreasonable ;④The operation is very difficult. During the process of loading the oxygen cylinder, the operator must not only control the proper angle of the forward tilt of the truck body, but also push the truck forward to insert the

pallet into the lower end of the oxygen cylinder; If the

angle of inclination is too small, the gap between the oxygen cylinder and the ground is not enough to be inserted into the pallet, and if the forward tilt angle of the transport vehicle is too large, the oxygen cylinder will fall forward, making it difficult to unload the oxygen cylinder.

Login to View More

Login to View More  Login to View More

Login to View More