Coal-fired unit ash silo gasification air supply system and method

A coal-fired unit and gas supply system technology, which is applied in the field of ash storage and transportation, can solve the problems of increasing unit power consumption, limited operating life of electric heating, poor reliability, etc., to meet environmental protection emission requirements, improve supply reliability, The effect of avoiding operational risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

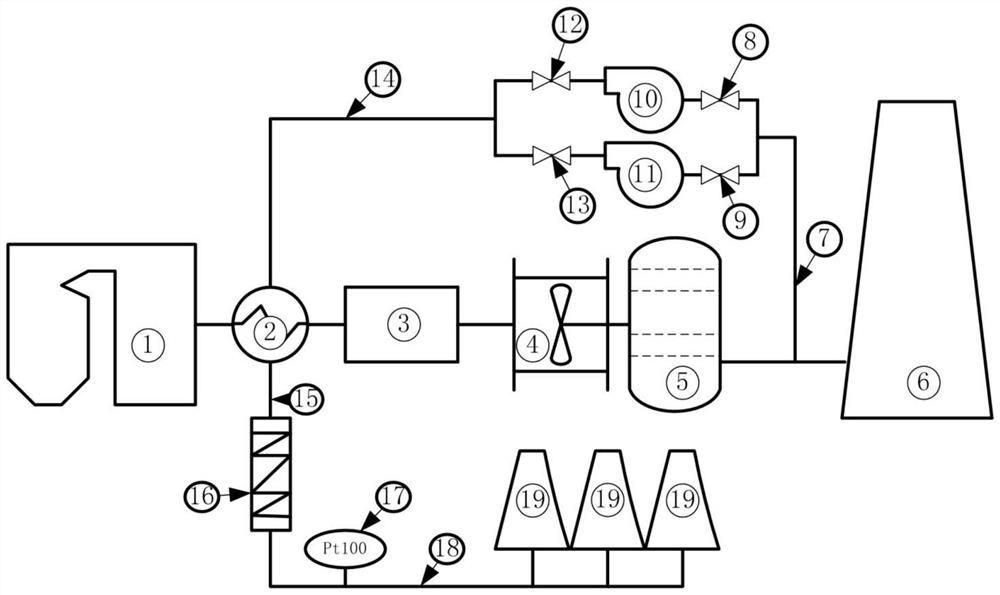

[0024] Such as figure 1 As shown, the present invention includes a coal-fired boiler 1, a heat exchanger 2, an electric dust collector 3, an induced draft fan 4, a desulfurization tower 5, a chimney 6, a gasification fan inlet pipe 7, an inlet manual door, an outlet manual door, a gasification fan, Gasification fan outlet pipe 14, heat exchanger outlet pipe 15, electric heater 16, temperature sensor 17, ash storehouse gasification wind pipe 18 and ash storehouse 19.

[0025] The net flue gas at the outlet of the desulfurization tower 5 is divided into two paths, one of which is connected to the gasification fan through the inlet pipe 7, and the other is discharged into the atmosphere through the chimney 6. The gasification fans are arranged side by side, with a manual door at the entrance and a manual door at the exit. A heat exchanger 2 is installed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com