Anti-blue-light light guide plate, preparation method thereof, backlight module and liquid crystal display panel

A light guide plate and anti-blue light technology, applied in the field of optical materials, can solve the problems of brightness and chromaticity deterioration of the optical effect of the light guide plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

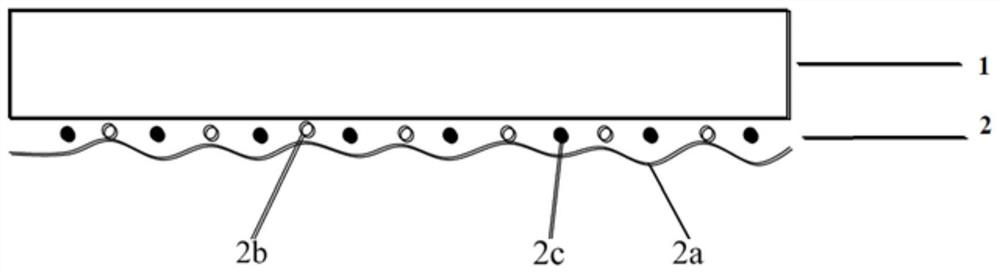

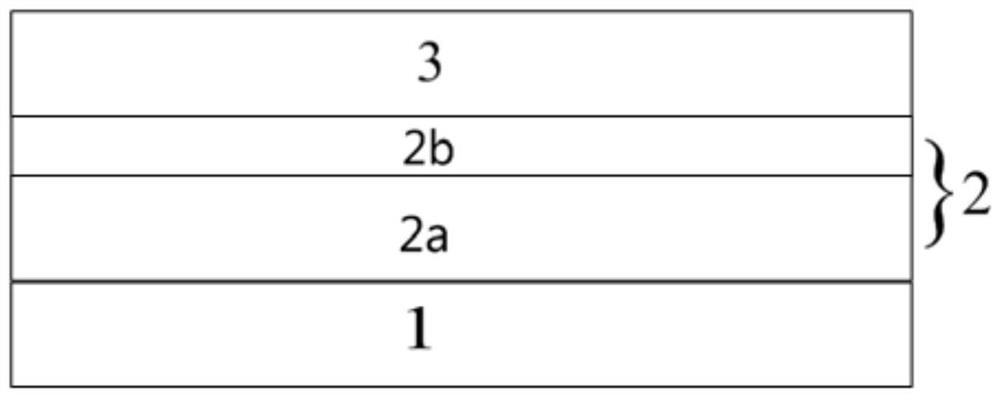

[0054] The present invention also provides a method for preparing the anti-blue light guide plate described in the above technical solution, comprising: coating the anti-blue light coating liquid on one side surface of the main body of the light guide plate, and curing after UV irradiation to form an anti-blue light functional layer.

[0055] Wherein, the raw material components of the anti-blue light coating solution are consistent with those described in the previous technical solution, and will not be repeated here.

[0056] In the present invention, the coating method is not particularly limited, and it can be a conventional coating method known to those skilled in the art, such as rod coating method, dimple coating method, knife coating method or spray coating method.

[0057] After the above coating, UV light curing is carried out. In the present invention, the conditions of the UV light are: the UV lamp used is a 320-480mm long high-pressure mercury lamp, and the lengt...

Embodiment 1

[0066] 1. Raw materials for anti-blue light layer coating liquid:

[0067]

[0068] Stir and mix the above components in proportion at room temperature to obtain an anti-blue light coating solution.

[0069] 2. Preparation of light guide plate:

[0070] Spray the anti-blue light coating liquid on the upper surface of the polycarbonate light guide plate (thickness 0.4mm), and then perform UV light curing, the conditions are: the UV lamp tube is a 400mm long high-pressure mercury lamp, the power is 1800W, and the irradiation is 40s; After the above treatment, a light guide plate with an anti-blue light functional layer was obtained, wherein the thickness of the anti-blue light functional layer was 2 μm.

Embodiment 2

[0072] 1. Raw materials for anti-blue light layer coating liquid:

[0073]

[0074] Stir and mix the above components in proportion at room temperature to obtain an anti-blue light coating solution.

[0075] 2. Preparation of the light guide plate: the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Brightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com