LED epitaxial structure and growth method thereof

A growth method and epitaxial structure technology are applied in the field of LED manufacturing to achieve the effects of improving efficiency, improving luminous efficiency and expanding capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

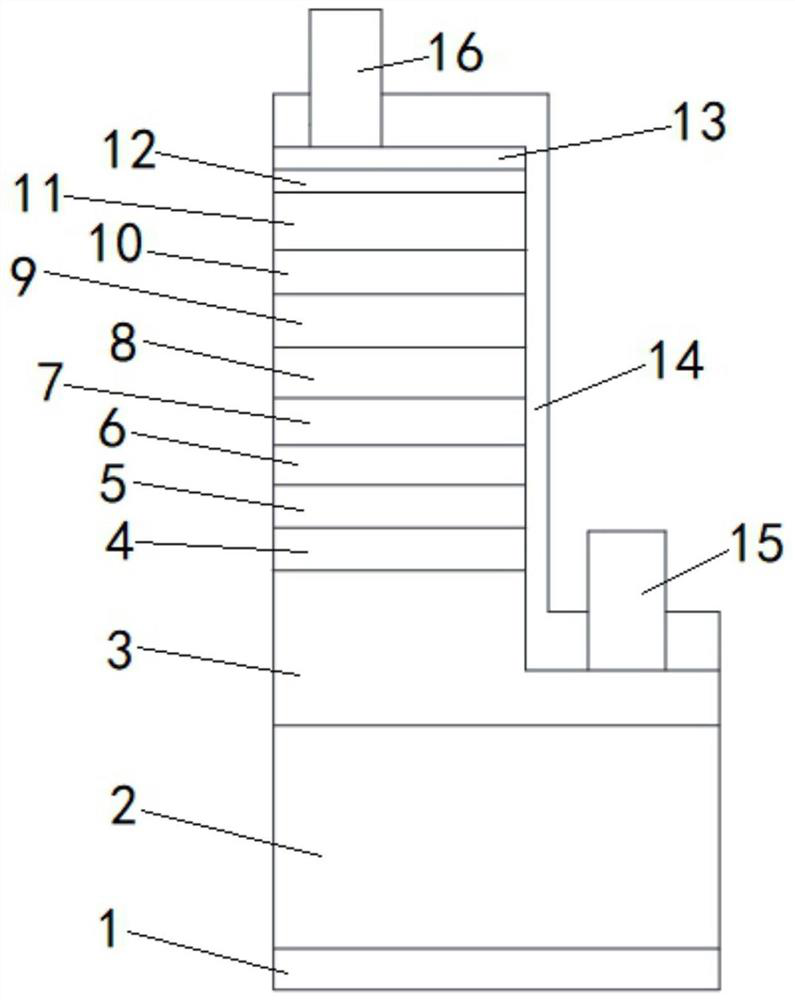

[0030] see figure 1 , a method for growing an LED epitaxial structure. This embodiment is applied to improving the luminous brightness of the LED epitaxial structure.

[0031] A method for growing an LED epitaxial structure, comprising sequentially growing a first GaN layer 2, a second GaN layer 3, a third GaN layer 4, a first superlattice layer 5, a second superlattice layer 6, The light emitting layer, the first P-type GaN layer 9, the P-type AlGaN layer 10, the second P-type GaN layer 11 and the third P-type GaN layer 12, such as figure 1 shown.

[0032]In this application, MOCVD (metal organic compound chemical vapor deposition) is used to grow high-brightness GaN-based LED epitaxial structures, and high-purity H 2 , high purity N 2 At least one of them is used as a carrier gas; high-purity NH is used 3 (Ammonia) as N source; metal-organic source trimethylgallium (TMGa) or triethylgallium (TEGa) as gallium source; trimethylindium (TMIn) as indium source; trimethylalumi...

Embodiment 2

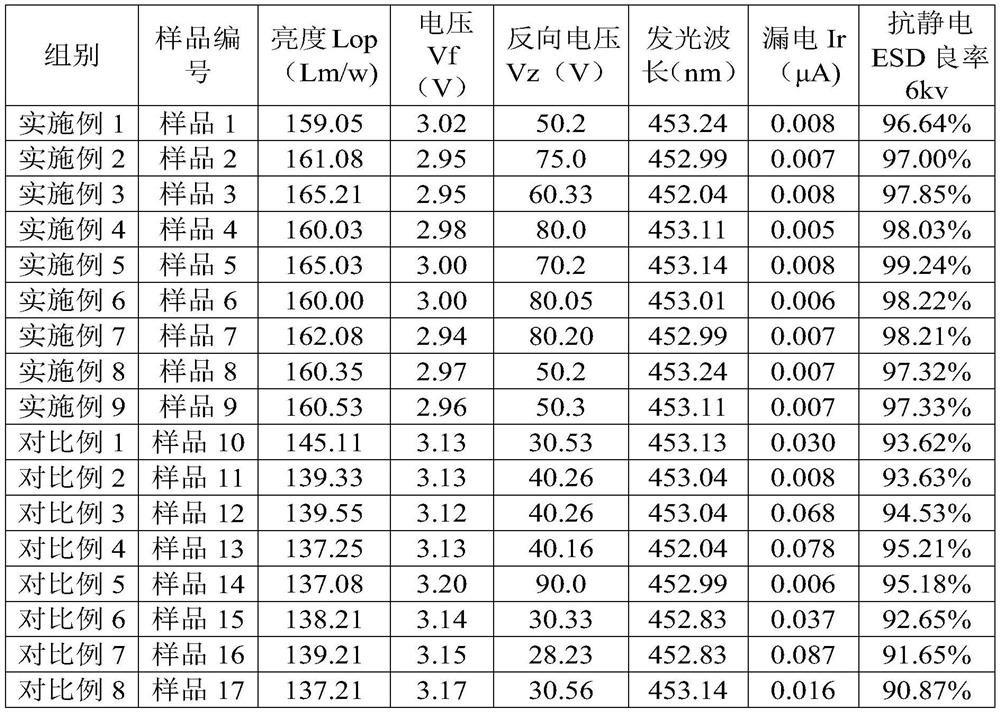

[0056] The difference between this embodiment and Embodiment 1 is that in Step 5, when growing the first superlattice layer 5, N-type GaN doped with Si and In not doped with Si are alternately grown. x Ga (1-x) N, the number of alternate growth cycles is 10, and the obtained whole chip particle is sample 2.

Embodiment 3

[0058] The difference between this embodiment and Embodiment 1 is that in Step 5, when growing the first superlattice layer 5, N-type GaN doped with Si and In not doped with Si are alternately grown. x Ga (1-x) N, the number of alternate growth cycles is 8, and the obtained whole chip particles are sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com