Brushless doubly-fed induction generator efficiency optimization control method and system

A technology of generator efficiency and optimal control, applied in motor generator control, generator control circuit, control system, etc., can solve the problem of low efficiency of brushless doubly-fed induction generator, and achieve efficiency improvement, efficiency maximization, Reasonable distribution of the effect of improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

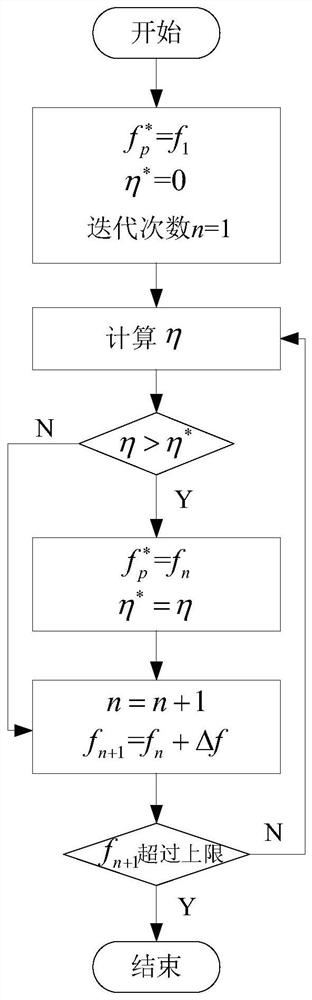

[0058] A brushless doubly-fed induction generator efficiency optimization control method, such as figure 1 shown, including the following steps:

[0059] (1) In the current control cycle, according to the feedback value U of the power winding voltage amplitude p Calculate the output power P of the motor with the resistive load value R out , according to the DC bus voltage U dc and DC bus current I dc Calculate the DC input power P of the motor dc , and obtain the rotor angular velocity ω of the brushless doubly-fed induction generator r and electromagnetic torque T em , to calculate the mechanical power P converted to the input electromagnetic power em , so as to calculate the motor efficiency of the current control cycle as η=P out / (P em +P dc );

[0060] In this example, the output power P out The calculation formula is: DC input power P dc The calculation formula is: P dc =U dc I dc ;

[0061] In an optional embodiment, in step (1), the rotor angular velo...

Embodiment 2

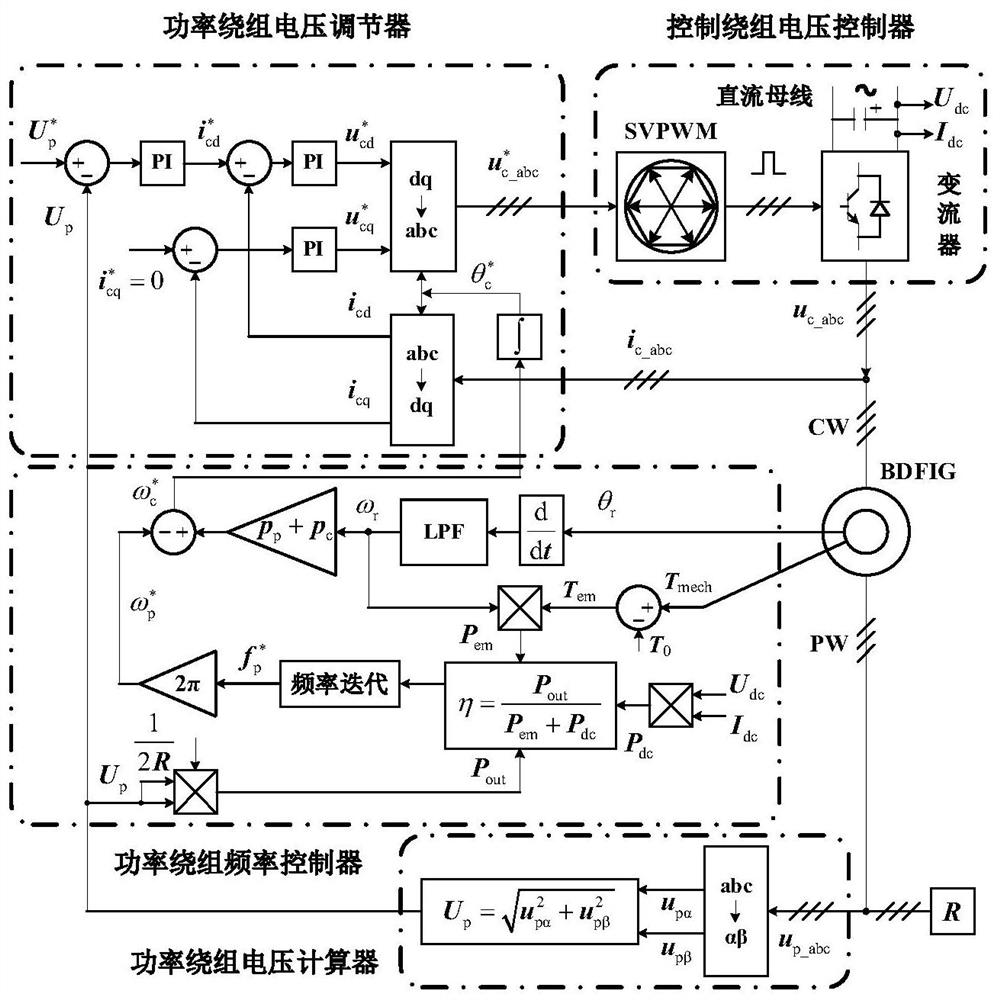

[0085] Provides a brushless doubly-fed induction generator efficiency optimization control system, such as figure 2 As shown, including: power winding frequency controller, power winding voltage calculator, power winding voltage regulator and control winding voltage controller;

[0086] The power winding frequency controller includes: efficiency calculation module, frequency iteration module and control module;

[0087] The efficiency calculation module is used to feed back the value U according to the voltage amplitude of the power winding in the current control cycle p Calculate the output power P of the motor with the resistive load value R out , according to the DC bus voltage U dc and DC bus current I dc Calculate the DC input power P of the motor dc , and obtain the rotor angular velocity ω of the brushless doubly-fed induction generator r and electromagnetic torque T em , to calculate the mechanical power P converted to the input electromagnetic power em , so as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com