Manufacturing method of multilayer board blind hole buried hole filling packaging substrate

A technology for packaging substrates and manufacturing methods, which is applied in the manufacture of printed circuits, coating of non-metallic protective layers, and processing of insulating substrates/layers, etc. Substrate functionality, reliability and other issues, to achieve good blind hole filling effect, improve functionality and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The preferred embodiments of the present invention will be further described in detail below.

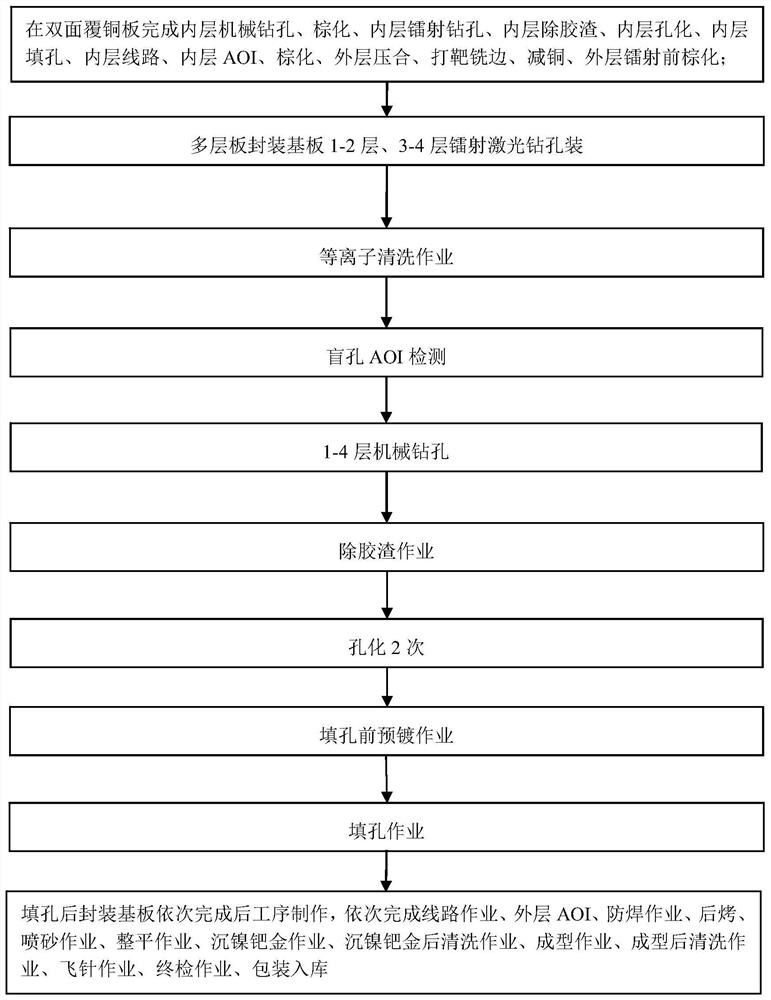

[0062] A method for manufacturing a multilayer board blind hole buried hole filling process packaging substrate, such as figure 1 shown, including the following steps:

[0063] 1. Prepare double-sided copper clad laminates, complete inner layer mechanical drilling, browning, inner layer laser drilling, inner layer desmearing, inner layer holeization, inner layer hole filling, inner layer wiring, inner layer AOI, browning Melting, outer layer lamination, target milling, copper reduction, outer layer pre-laser browning, outer layer laser drilling.

[0064] This step is the process flow of the package substrate before the embodiment, in which the double-sided copper-clad laminate is the inner layer cutting board, and the thickness of the core board is in the range of 0.04mm-0.1mm (such as 0.04mm, 0.06mm, 0.08mm, 0.1mm, etc. thickness), Among them, the thickness of the bottom c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com