High-pressure polymerization process of ethylenically unsaturated monomers in polymerization reactor

A polymerization reactor and high-pressure polymerization technology, applied in chemical instruments and methods, chemical/physical/physicochemical fixed reactors, methods for chemically changing substances using atmospheric pressure, etc., can solve time-consuming and low-yield problems And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

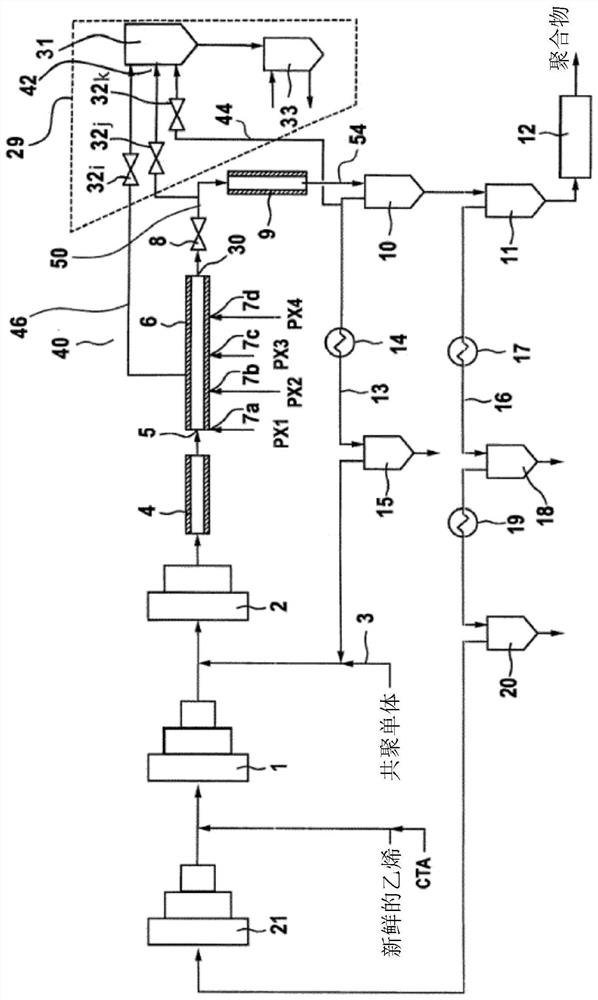

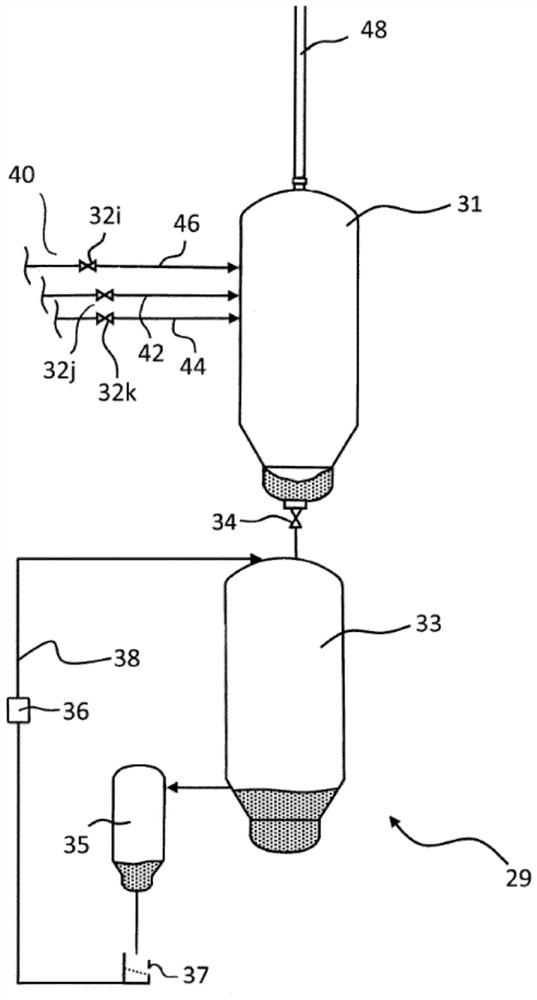

[0067] The process of the present invention relates to a process for polymerizing ethylene and optionally one or more comonomers to obtain ethylene-based polymers in a high-pressure polymerization system which allows to significantly reduce the duration of reactor shutdown. Therefore, the effective operating time of an apparatus for polymerization or copolymerization of ethylenically unsaturated monomers can be significantly increased.

[0068] It should be understood that the use of "and / or" is defined inclusively such that the term "a and / or b" should be understood to include the following groups: "a and b", "a or b", "a", "b". Preferably, "and" in most cases "a and / or b" refer to two entities "a" and "b", wherein at least one of said entities is present in said embodiment.

[0069] It should be noted that the terms "above" and "top" refer to the arrangement of elements in the high pressure polymerization system, as assembled and as used and according to the gravity of the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com