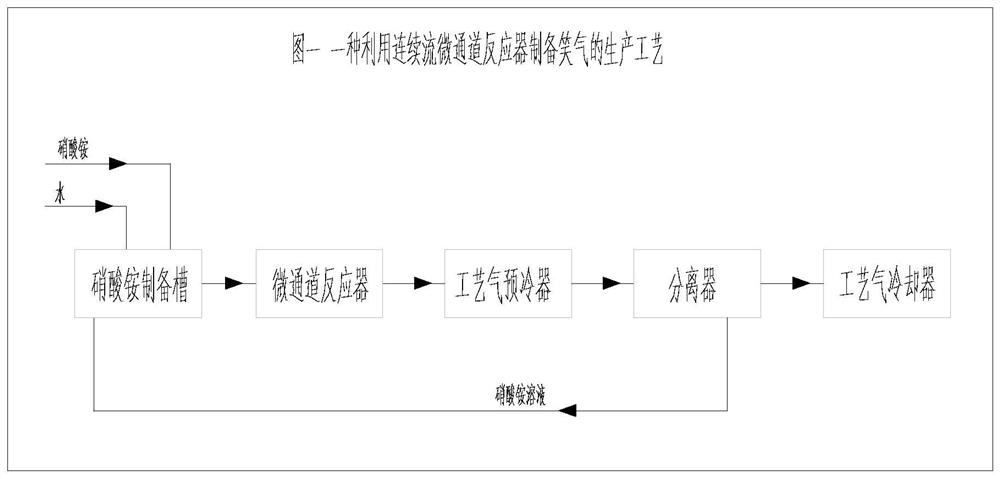

Production process for preparing laughing gas by using continuous flow microchannel reactor

A technology of microchannel reactor and channel reactor, which is applied in chemical/physical/physicochemical reactors, nitrous oxide, chemical instruments and methods, and can solve the problems of high risk, low safety factor, and low liquid holding capacity and other issues, to achieve the effect of low cost, reduced material consumption, and less side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of production technology that utilizes continuous flow microchannel reactor to prepare laughing gas, comprises the following steps:

[0048] (a) Take solid ammonium nitrate as raw material, with an annual output of 1000 tons of laughing gas;

[0049] (b) 1950 tons of ammonium nitrate is added to 100 tons of water earlier to prepare a mass concentration of 95% ammonium nitrate solution, with a quality of 2050 tons;

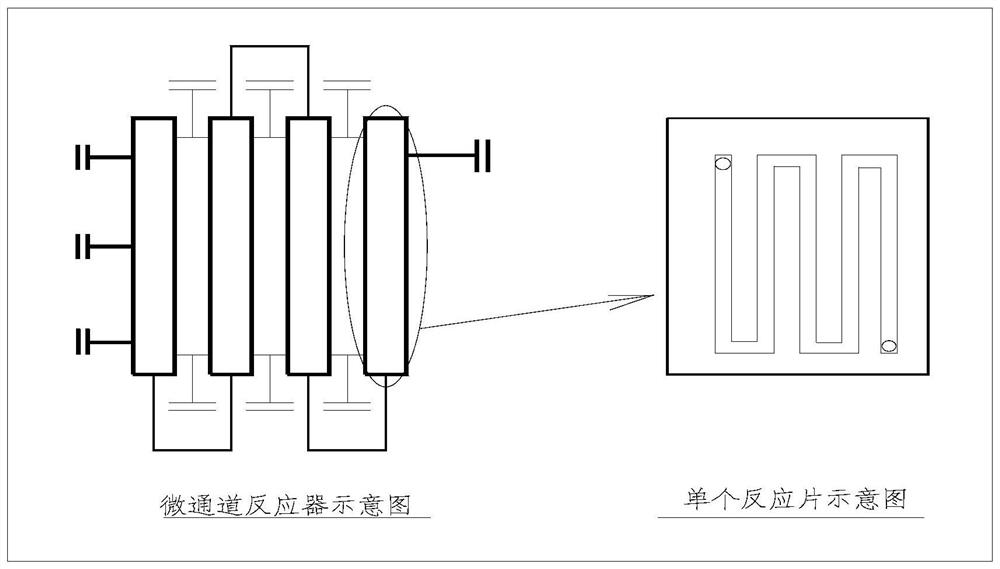

[0050] (c) the ammonium nitrate solution obtained in step (b) is delivered to the microchannel reactor by a pump, and the reactor is passed through an external heating source to maintain the reaction temperature at 220~225° C. Ammonium nitrate is decomposed into laughing gas and water, and the yield 98-99%. The reactor flux per hour is 280kg, while the liquid holding capacity of the reactor with an annual flux of 2000 tons is only 1L, and the residence time is 1 to 2 minutes;

[0051]

[0052]

[0053] d) The gas mixture containing a large amo...

Embodiment 2

[0057] A kind of production technology that utilizes continuous flow microchannel reactor to prepare laughing gas, comprises the following steps:

[0058] (a) be 95% ammonium nitrate solution as raw material with the mass concentration directly produced by the factory, its temperature is about 125 ℃, annual output 1000 tons of laughing gas;

[0059] (b) The 95% concentration of ammonium nitrate solution prepared by the original process is transported to the microchannel reactor by a pump, and heated to 220-225°C in the reactor, and the ammonium nitrate is decomposed into laughing gas and water, and the yield is about 98% ~99%, the yield did not change, but the composition of the output was different due to the presence of gaseous ammonia in the plant's ammonium nitrate solution. The flux of the reactor per hour is still 280kg, and the liquid holding capacity of the reactor with an annual flux of 2000 tons is about 1L, and the residence time is 1 to 2 minutes;

[0060]

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com