Preparation method of polyphenylene sulfide composite material suitable for boundary lubrication interval

A composite material and boundary lubrication technology, applied in the field of composite material preparation, can solve the problems of public reports of nano-zinc oxide modified PPS-based materials, poor wear resistance, large friction coefficient of pure PPS resin, etc., to make up for the lack of bearing capacity, The effect of high production efficiency and wide application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Nano-zinc oxide particle-filled polyphenylene sulfide material preparation method:

[0040] (1) drying the nano-zinc oxide particles at 70° C. for 10 h;

[0041] (2) Pre-dry the PPS pellets at 120°C for 3 hours;

[0042] (3) Using a twin-screw extruder to disperse and granulate nano zinc oxide particles in the PPS resin matrix. Barrel temperature 290°C-320°C, screw speed 200rpm;

[0043] (4) pre-drying the pellets obtained in step (3) at 120° C. for 3 hours;

[0044] (5) Injection molding the dried pellets. The barrel temperature is 290°C-320°C, and the mold temperature is 140°C.

[0045] In the prepared composite material, the volume fraction of nano zinc oxide particles is 3%, and the volume fraction of PPS resin matrix is 97%.

Embodiment 2

[0046] Example 2 Preparation method of nano zinc oxide particles and chopped carbon fiber filled polyphenylene sulfide material:

[0047] (1) drying the nano-zinc oxide particles and chopped carbon fibers at 70° C. for 10 h;

[0048] (2) Pre-dry the PPS pellets at 120°C for 3 hours;

[0049] (3) Dispersing nano zinc oxide particles and carbon fibers in the PPS resin matrix by a twin-screw extruder and granulating them. Barrel temperature 290°C-320°C, screw speed 200rpm;

[0050] (4) pre-drying the pellets obtained in step (3) at 120° C. for 3 hours;

[0051] (5) Injection molding the dried pellets. The barrel temperature is 290°C-320°C, and the mold temperature is 140°C.

[0052] In the prepared composite material, the volume fraction of nano zinc oxide particles is 3%, the volume fraction of carbon fiber is 10%, and the volume fraction of PPS resin matrix is 97%.

Embodiment 3

[0053] Example 3 Preparation method of nano zinc oxide particles and chopped glass fiber filled polyphenylene sulfide material:

[0054] (1) drying the nano zinc oxide particles and chopped glass fibers at 70°C for 10h;

[0055] (2) Pre-dry the PPS pellets at 120°C for 3 hours;

[0056] (3) Dispersing nano-zinc oxide particles and glass fibers in the PPS resin matrix by a twin-screw extruder and granulating them. Barrel temperature 290°C-320°C, screw speed 200rpm;

[0057] (4) pre-drying the pellets obtained in step (3) at 120° C. for 3 hours;

[0058] (5) Injection molding the dried pellets. The barrel temperature is 290°C-320°C, and the mold temperature is 140°C.

[0059]In the prepared composite material, the volume fraction of nano zinc oxide particles is 3%, the volume fraction of glass fiber is 10%, and the volume fraction of PPS resin matrix is 97%.

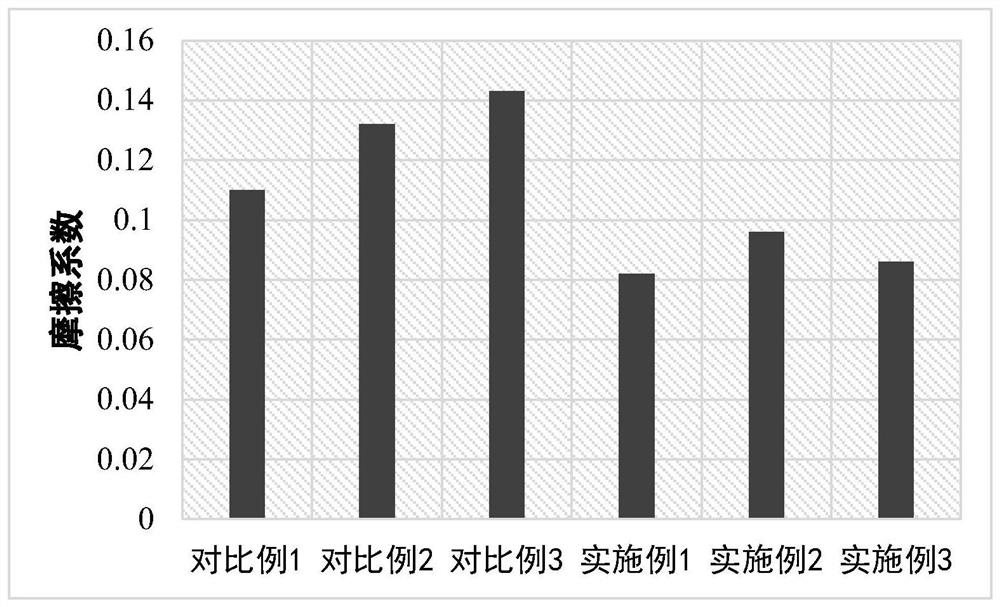

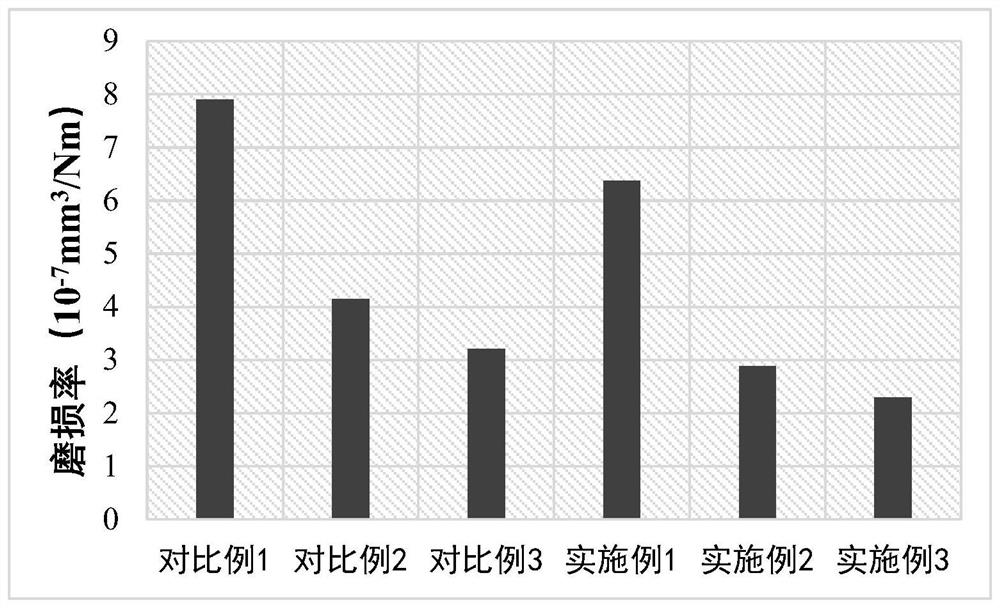

[0060] Test method and result of friction coefficient and wear rate

[0061] Using polyalphaolefin base oil as t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com