Preparation method of plant-source slow-release anti-mosquito functional pure cotton fabric

A plant-derived, mosquito-proof technology, applied in plant fibers, textiles and papermaking, fiber processing, etc., can solve problems such as environmental pollution, unfavorable environmental protection principles, and chemical synthetic pesticides. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

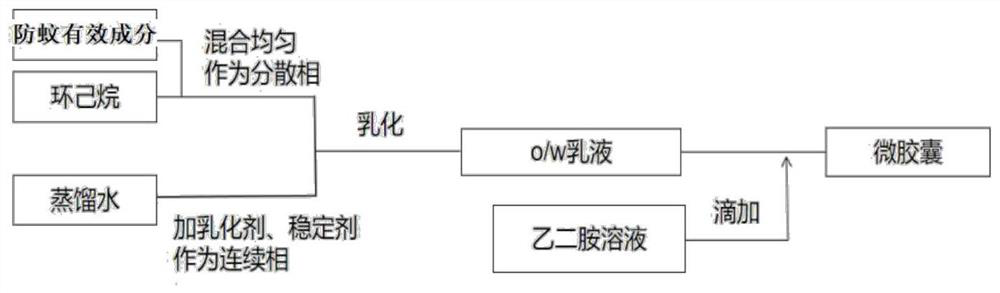

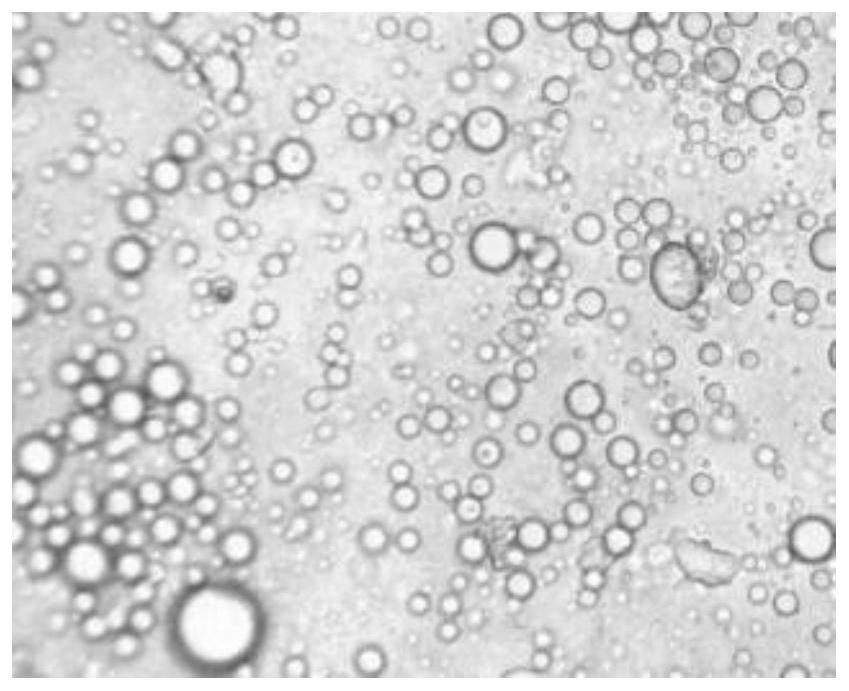

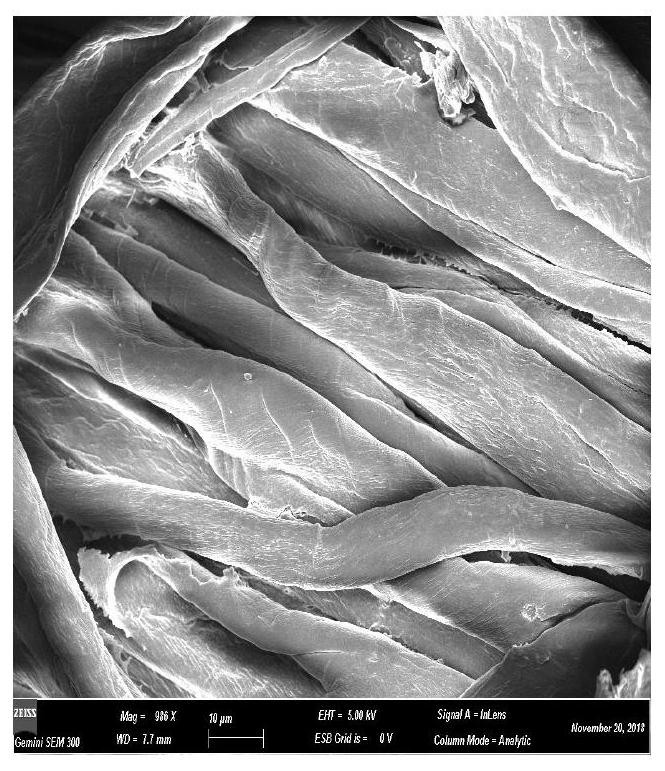

[0023] see Figure 1-6 , the present invention provides a technical solution: a preparation method of plant source slow-release anti-mosquito functional pure cotton fabric, comprising the following steps: a. extracting and making anti-mosquito active ingredients, b. ethylenediamine aqueous solution with a concentration of 2% Preparation, c. Production of microcapsules, d. Foam finishing agent formula, e. Fabric finishing method, the anti-mosquito active ingredients extracted from mosquito-proof plants, the anti-mosquito active ingredients and cyclohexane at a ratio of 1:1 Mix at a volume ratio of -3, and gradually add a small amount of emulsifier, 1% PVA and distilled water, stir evenly at a low speed as the continuous phase, gradually add the dispersed phase to the continuous phase at a certain speed, and adjust to the highest level after the addition is completed Stirring speed, after 10-20min to obtain a stable o / w emulsion, slowly add the prepared ethylenediamine aqueous s...

Embodiment 1

[0026]Example 1: Ultrasonic extraction of plant-derived anti-mosquito active ingredients, material ratio: 1:10, ultrasonic temperature 50°C, ultrasonic time 60min, effective anti-mosquito ingredients peppermint extract: sand ginger oil extract: red eucalyptus extract = 1: 1:1, anti-mosquito active ingredients: cyclohexane=1:1, add a small amount of emulsifier, 1% concentration of PVA and distilled water and stir evenly as a dispersed phase, add a small amount of emulsifier, 1% concentration of PVA and distilled water and stir evenly at a low speed As the continuous phase, gradually add the dispersed phase to the continuous phase at a certain speed, adjust to the highest stirring speed after the dropwise addition, and obtain a stable o / w emulsion after 10 minutes, and prepare the prepared water-soluble single phase with a concentration of 2%. The aqueous solution of terephthaloyl chloride and ethylenediamine in a ratio of 1:1 is slowly added to the o / w emulsion, and after stirri...

Embodiment 2

[0027] Example 2: Ultrasonic extraction of plant-derived anti-mosquito active ingredients, material ratio: 1:30, ultrasonic temperature 40°C, ultrasonic time 40min, take effective anti-mosquito ingredients peppermint extract: sand ginger oil extract: red eucalyptus extract = 1 : 2: 3, anti-mosquito active ingredients: cyclohexane = 1: 2 Add a small amount of emulsifier, 1% concentration of PVA and distilled water and stir evenly as a dispersed phase, add a small amount of emulsifier, 1% concentration of PVA and distilled water and stir evenly at a low speed As the continuous phase, gradually add the dispersed phase to the continuous phase at a certain speed, adjust to the highest stirring speed after the dropwise addition is completed, and obtain a stable o / w emulsion after 20 minutes. The aqueous solution of terephthaloyl chloride and ethylenediamine in a ratio of 1:2 is slowly added to the o / w emulsion, stirred for 1 hour to obtain a solution of peppermint / sand ginger oil / red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com