Preparation process of high-strength base paper

A preparation process, high-strength technology, applied in special paper, paper, papermaking and other directions, can solve the problems of high wear degree, general friction resistance, high cost of use, improve structural strength, improve friction resistance, friction resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

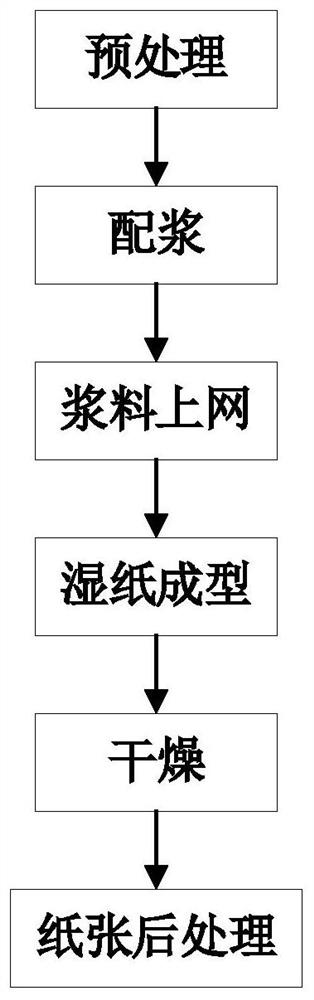

[0023] Example 1. A high-strength raw paper preparation process, such as figure 1 As shown, it consists of the following raw materials in parts by weight: 140-180 parts of paper pulp, 20-30 parts of titanium dioxide, 30-45 parts of calcium carbonate, 8-14 parts of sodium hydroxide, 10-20 parts of wood fiber, 20-50 parts of starch 20-30 parts of alum, 20-30 parts of antibacterial agent, 2-5 parts of crosslinking agent, 15-20 parts of paraffin, 8-15 parts of desiccant.

[0024] Its preparation steps are as follows:

[0025] A, pretreatment: take calcium carbonate, starch and wood fiber and carry out pulverizing and grinding, and filter and remove impurities to the coarse material after grinding; After removing impurities, carry out beating treatment, obtain a product;

[0026] B. Mixing pulp: mix product A, paper pulp, titanium dioxide, sodium hydroxide, starch, alum and paraffin, and add a cross-linking agent after mixing uniformly to obtain product B;

[0027] C. Slurry onl...

Embodiment 2

[0033] Example 2. A high-strength raw paper preparation process, such as figure 1 As shown, the following raw material composition by weight: 150-170 parts of paper pulp, 22-28 parts of titanium dioxide, 35-40 parts of calcium carbonate, 10-12 parts of sodium hydroxide, 14-16 parts of wood fiber, 30-40 parts of starch , 24-26 parts of alum, 22-28 parts of antibacterial agent, 3-4 parts of crosslinking agent, 17-18 parts of paraffin, 10-13 parts of desiccant.

[0034] Its preparation steps are as follows:

[0035] A, pretreatment: take calcium carbonate, starch and wood fiber and carry out pulverizing and grinding, and filter and remove impurities to the coarse material after grinding; After removing impurities, carry out beating treatment, obtain a product;

[0036] B. Mixing pulp: mix product A, paper pulp, titanium dioxide, sodium hydroxide, starch, alum and paraffin, and add a cross-linking agent after mixing uniformly to obtain product B;

[0037] C. Slurry online: dilu...

Embodiment 3

[0043] Example 3. A high-strength raw paper preparation process, such as figure 1 As shown, it consists of the following raw materials in parts by weight: 160 parts of paper pulp, 25 parts of titanium dioxide, 37.5 parts of calcium carbonate, 11 parts of sodium hydroxide, 15 parts of wood fiber, 35 parts of starch, 25 parts of alum, 25 parts of antibacterial agent, 3.5 parts of joint agent, 17.5 parts of paraffin, 11.5 parts of desiccant.

[0044] Its preparation steps are as follows:

[0045] A, pretreatment: take calcium carbonate, starch and wood fiber and carry out pulverizing and grinding, and filter and remove impurities to the coarse material after grinding; After removing impurities, carry out beating treatment, obtain a product;

[0046] B. Mixing pulp: mix product A, paper pulp, titanium dioxide, sodium hydroxide, starch, alum and paraffin, and add a cross-linking agent after mixing uniformly to obtain product B;

[0047] C. Slurry online: dilute product b to 0.15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com