A hydraulic device that utilizes self-weight potential energy feedback to assist servo motor output torque

A technology of servo motor and output torque, which is applied in the field of servo motor to achieve the effect of increasing output torque, reducing power cost and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

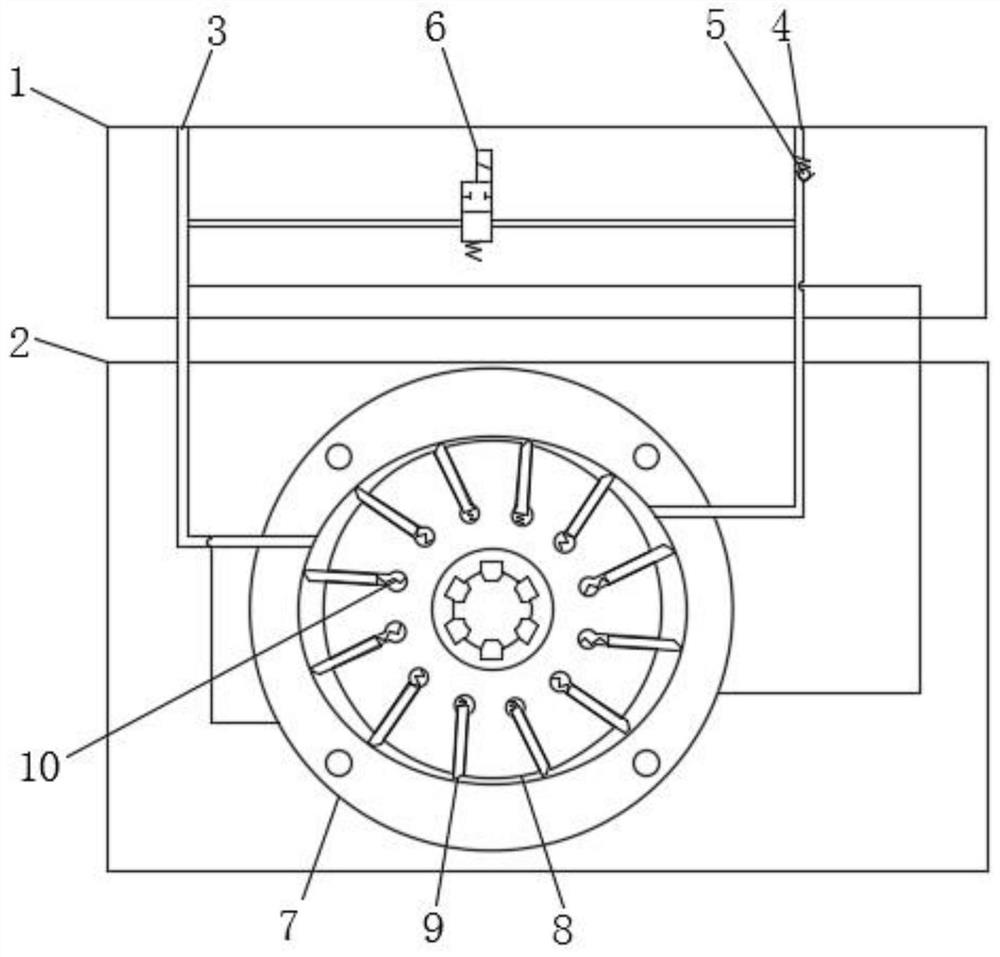

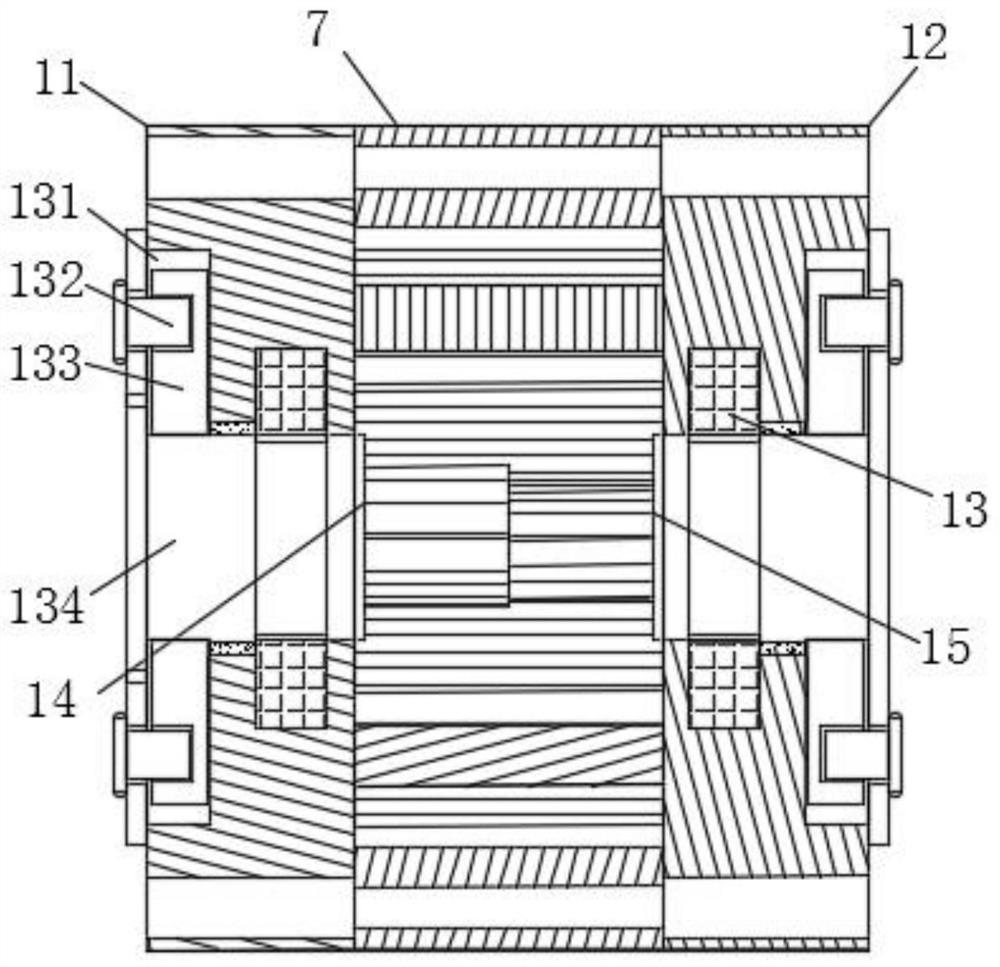

Embodiment 1

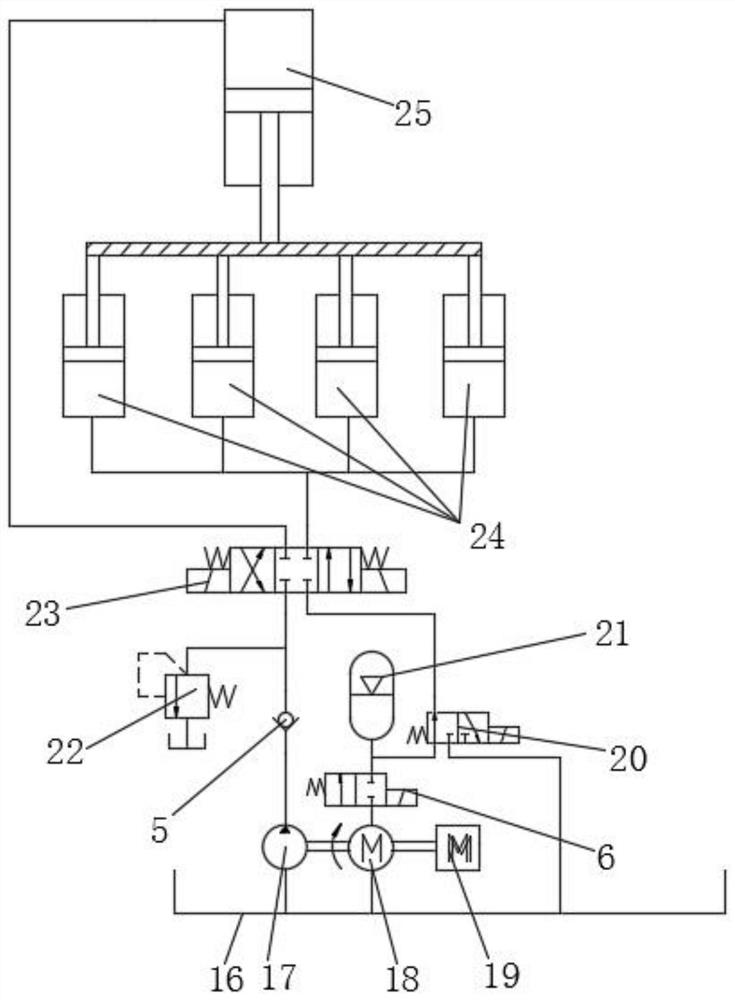

[0037] (1), the original use of 45KW servo driver, 50KW servo motor, 80cc+80cc double variable speed hydraulic pump.

[0038] (2), the main oil cylinder is a single-acting oil cylinder, the cylinder diameter is 510mm, the stroke is 1600mm, and the maximum working pressure is 25Mpa.

[0039] (3), the single-acting oil cylinder of the ascending auxiliary cylinder, the cylinder diameter is 120mm, the stroke is 1600mm, and the 4 cylinders are connected in parallel.

[0040] (4), the main oil cylinder dead weight descending accumulator can recover more than 72L / min.7Mpa hydraulic energy from the ascending auxiliary cylinder.

Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com