Near-net forming manufacturing process for hundred-ton special-shaped section ring forge piece

A technology of special-shaped section and manufacturing process, which is used in manufacturing tools, forging/pressing/hammering machinery, metal rolling, etc. The effect of production efficiency, reduction of production cost, and shortening of manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

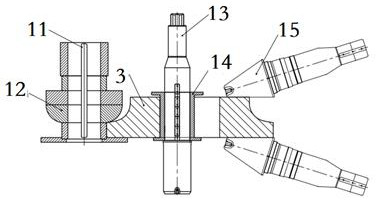

[0017] The applicant undertakes the special-shaped cross-section replacement ring forgings of 14Cr1MoⅣ material ordered by a certain customer. The finished product diagram is shown in the attachment. Figure 6 . The rough weight of this product is about 160 tons, and the finished product weighs about 102.5 tons.

[0018] Implementation of the present invention comprises the following steps:

[0019] 1) Load the raw material steel ingots that have passed the inspection into the furnace according to the heating process, heat the temperature to 1250°C±10°C, and hold the heat for ≥10 hours. Punching and reaming processes are used to make cylindrical blanks;

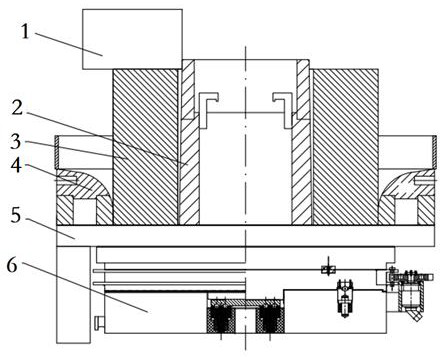

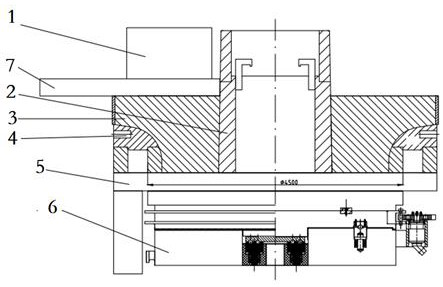

[0020] 2) After the steel ingot is heated and kept warm, it is released from the furnace, and the preformed cylindrical blank is put into the mold of the hydraulic press according to the forging process on the 13,500-ton hydraulic press, and the hammer anvil of the hydraulic press cooperates with the rotating base to comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com