Mold accessory maintenance equipment and use method thereof

A mold and accessories technology, applied in the field of mold accessories maintenance equipment, can solve the problems of inconvenience, affecting the maintenance effect, uneven distribution of maintenance oil film in the cavity of the mold, etc., and achieve the effect of uniform distribution and reduced force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

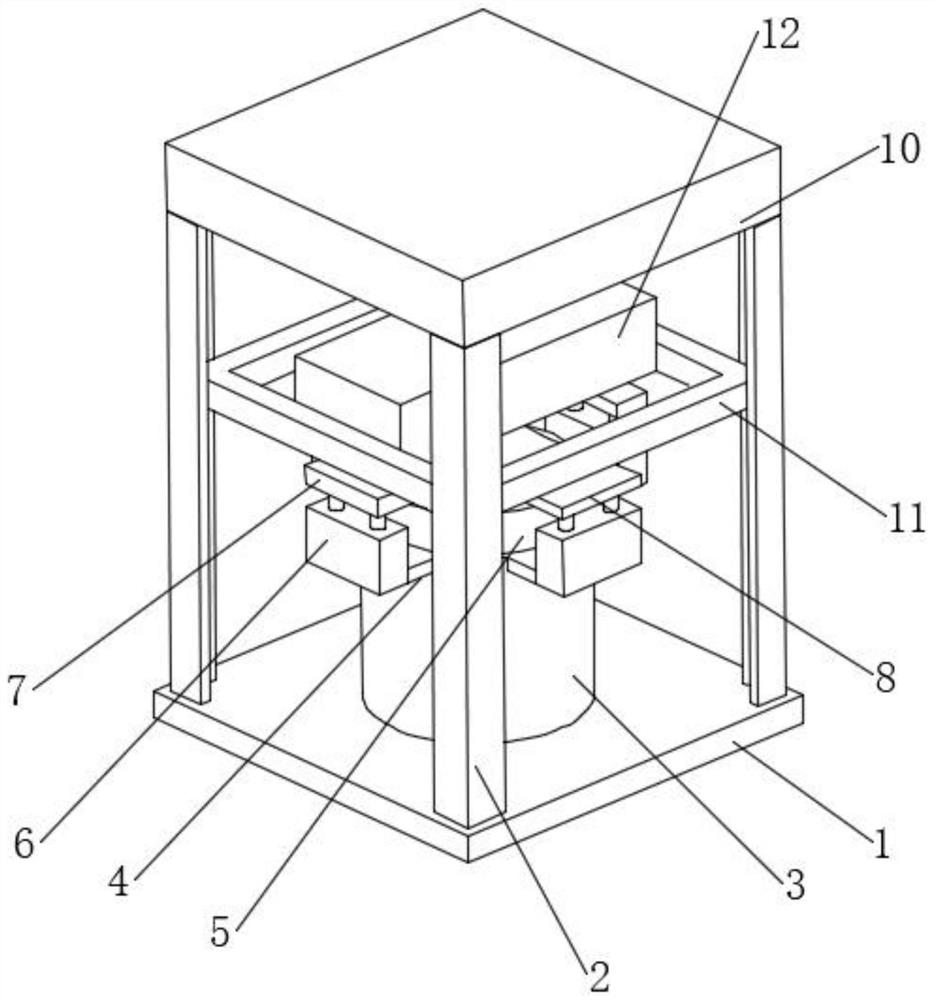

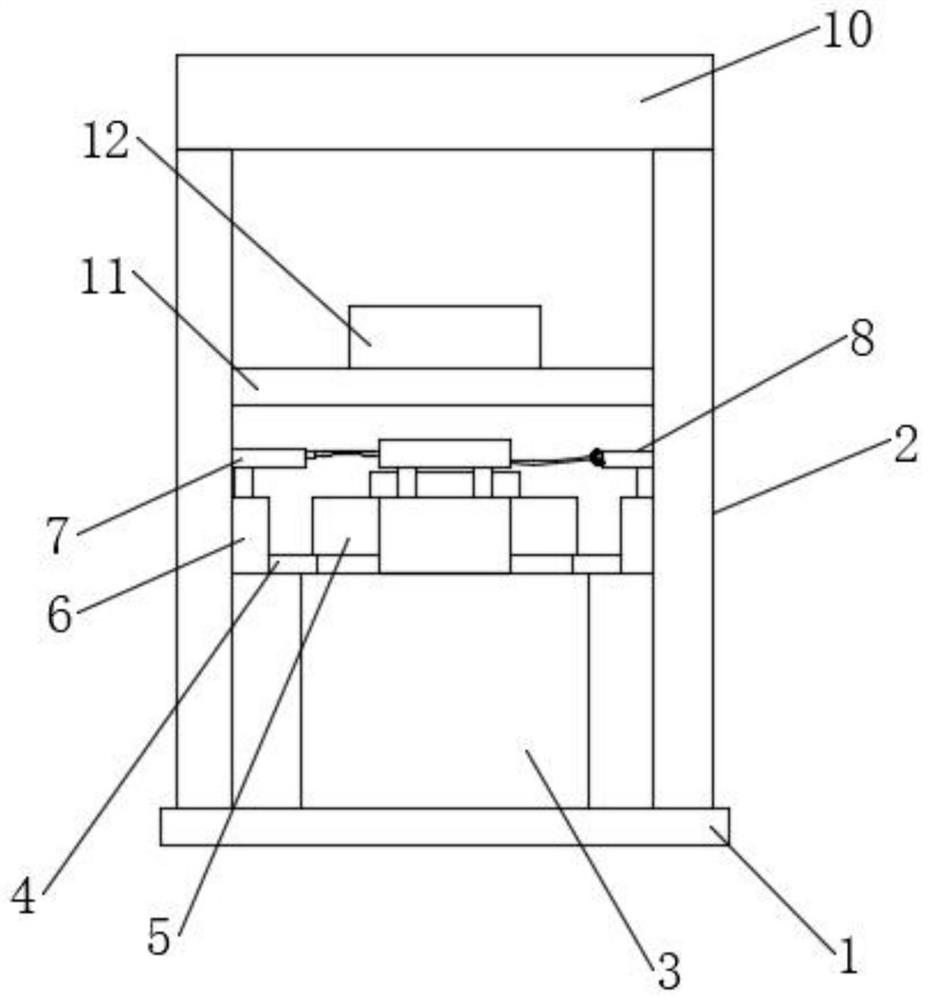

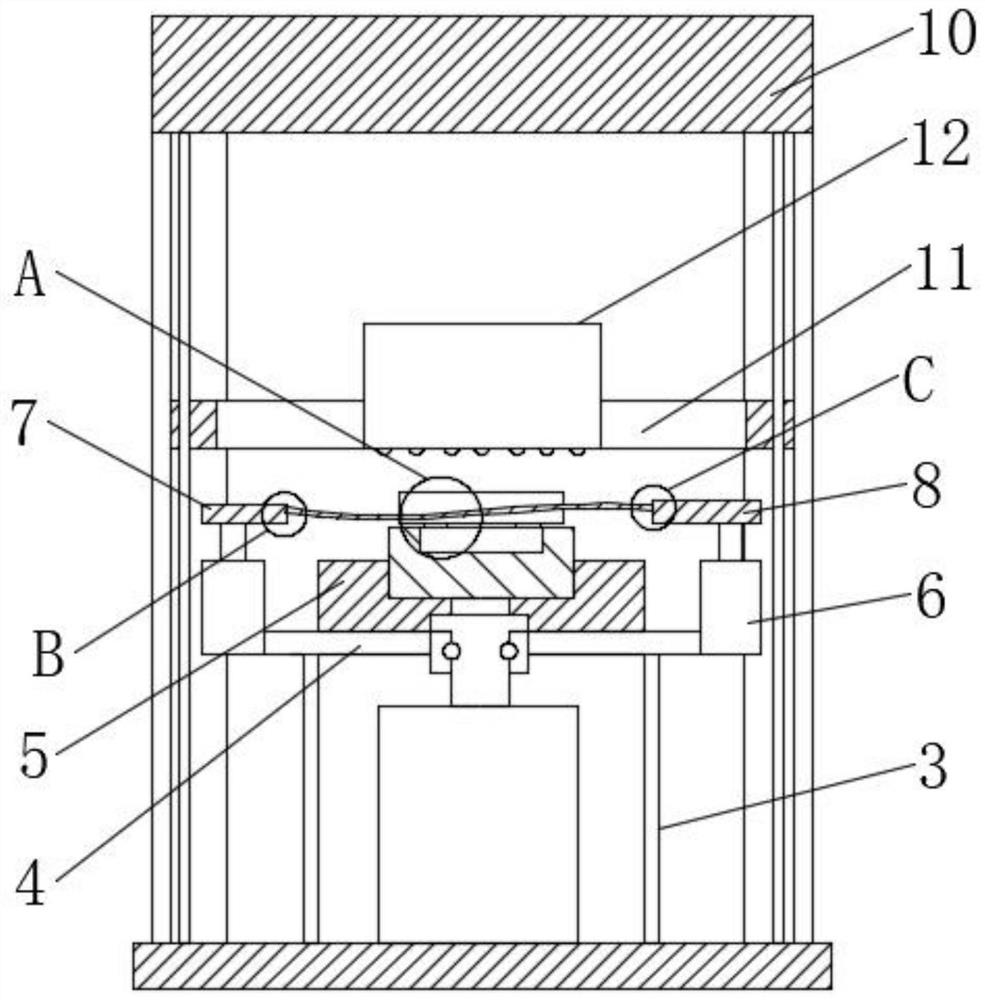

[0043] see Figure 1-3, a maintenance equipment for mold parts, including a workbench 1, a support column 3 and a plurality of vertical slide rails 2 are fixedly connected to the workbench 1, and a reinforcement beam is fixedly connected to the outer wall of the vertical slide rail 2, and the reinforcement beam is made of stainless steel and the support column 3 is located in the vertical slide rail 2, the top of the support column 3 is fixedly connected to the extension platform 4, the extension platform 4 is rotatably connected to the bearing platform 5, and the support column 3 is fixedly connected to the servo motor, and the power of the servo motor The output end is fixedly connected to the bearing platform 5, which is convenient to control the rotation of the bearing platform 5. There are installation grooves dug on the bearing platform 5, two pairs of installation frames 6 are fixedly connected to the extension platform 4, and the two installation frames 6 are respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com