Battery pack quick-changing and locking system of electric heavy truck

A technology for battery packs and heavy trucks, applied in the field of transportation, can solve problems such as hidden safety hazards, cab overturning, inconvenience, etc., and achieve the effects of low cost, improved reliability, and convenient battery replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

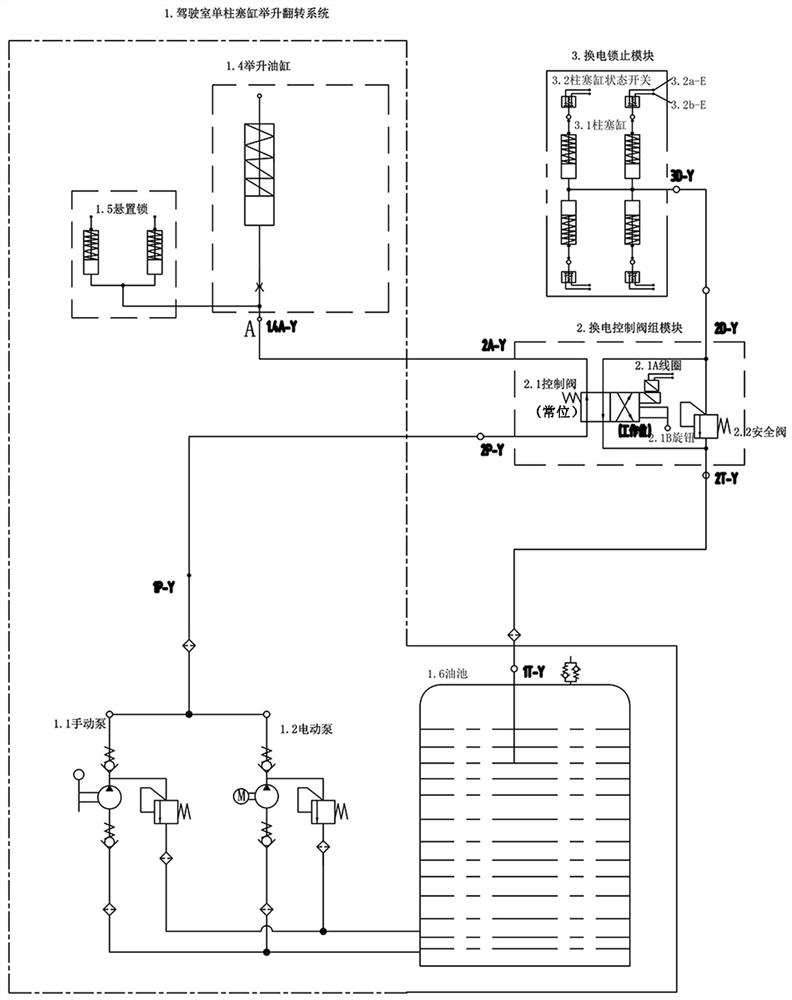

[0035] Embodiment 1: An application of a battery pack quick change and locking system based on a non-differential cab lift and flip system.

[0036] The battery pack quick change and locking system includes a cab lifting and turning hydraulic system 1 (oil pump 1.1 / 1.2, reversing valve 1.3, oil cylinder 1.4), a power-changing control valve group module 2, and a power-changing locking module 3 , Lift and replace the electronic control module 4. The connection relationship is as attached Figure 1.5a shown, . The power exchange control valve group module 2 is in communication with the lowering circuit of the cab lifting and turning hydraulic system 1, specifically the 2P-Y oil port of the power changing control valve group module and the lifting reversing valve in the lowering circuit of the cab lifting and turning hydraulic system 1 1.3 is connected to the oil port 1B1-Y between the lifting cylinder 1.4, and the oil port 2A-Y of the electric control valve group module is conne...

Embodiment 2

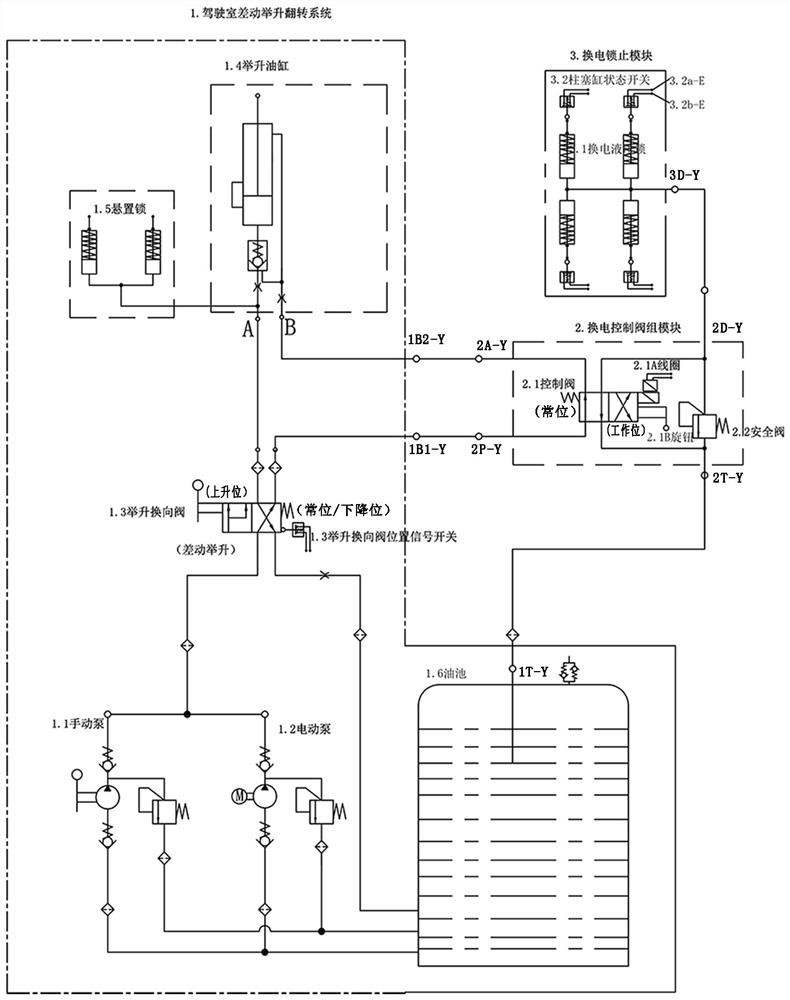

[0051] Embodiment 2: An application of a battery pack quick change and locking system based on a differential cab lift and flip system.

[0052] The battery pack quick change and locking system includes a cab lifting and turning hydraulic system 1 (oil pump 1.1 / 1.2, reversing valve 1.3, oil cylinder 1.4), a power-changing control valve group module 2, and a power-changing locking module 3 , Lift and replace the electronic control module 4. The connection relationship is as attached Figure 1.6 shown. Compared with Embodiment 1, only the lift cylinder 1.4 is replaced with a differential cylinder, and the lift reversing valve 1.3 is replaced with a differential lift valve. The other modules are connected in the same way and have the same functions. This is the advantage of the logic design of the present invention. High practicality.

Embodiment 3

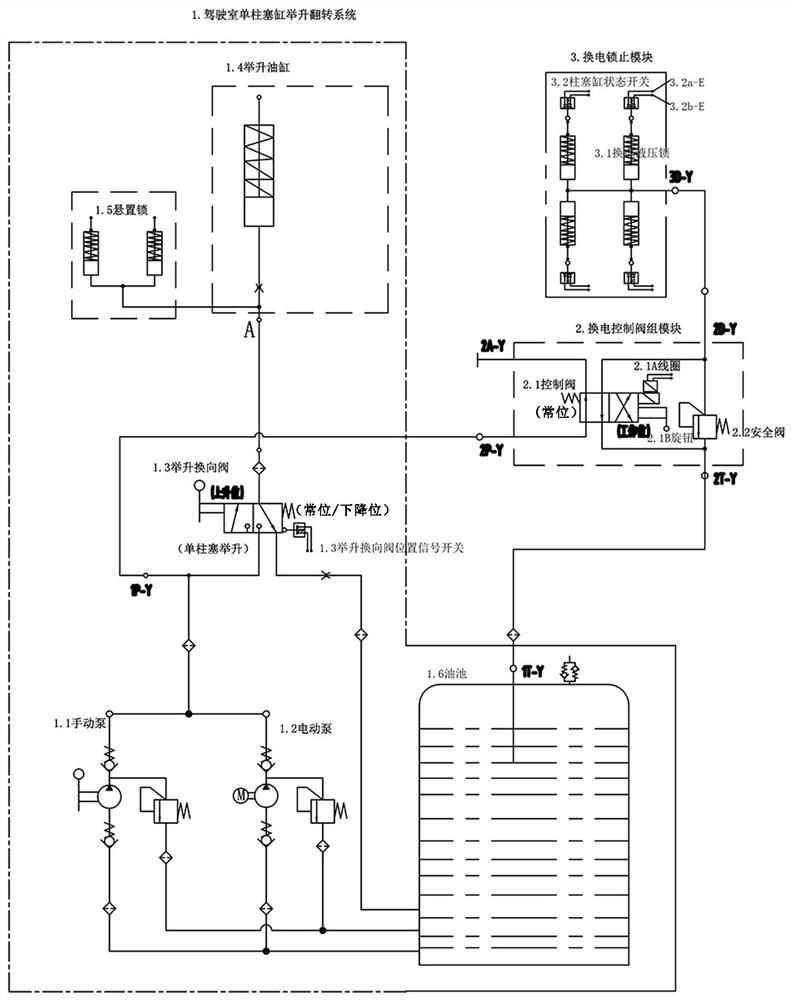

[0053] Embodiment 3: An application of a battery pack quick change and locking system based on a single-acting oil cylinder-based cab lifting and turning system.

[0054] The battery pack quick change and locking system includes a cab lifting and turning hydraulic system 1 (oil pump 1.1 / 1.2, reversing valve 1.3, oil cylinder 1.4), a power-changing control valve group module 2, and a power-changing locking module 3 , Lift and replace the electronic control module 4. The connection relationship is as attached Figure 1.7 shown. Compared with Embodiment 1, the lift cylinder 1.4 is a single-acting cylinder, the lift reversing valve 1.3 is a two-position three-way valve, and the oil inlet 2P-Y of the power exchange control valve group module 2 is connected to the oil outlet of the oil pump 1. Port 1P-Y; The oil outlet 2A-Y of the power-changing control valve group module 2 is sealed, and the other modules are connected in the same way and have the same function. This is the advant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com