Separation method for preparing basic magnesium carbonate and its sodium potassium salt by bittern mixed alkali method

A separation method, magnesium carbonate technology, applied in the direction of magnesium carbonate, alkali metal chloride, alkali metal halide purification, etc., can solve the problems of difficult bittern resources utilization, marine ecological environment damage, etc., and achieve easy industrialization and economic advantages Significant, utilization-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

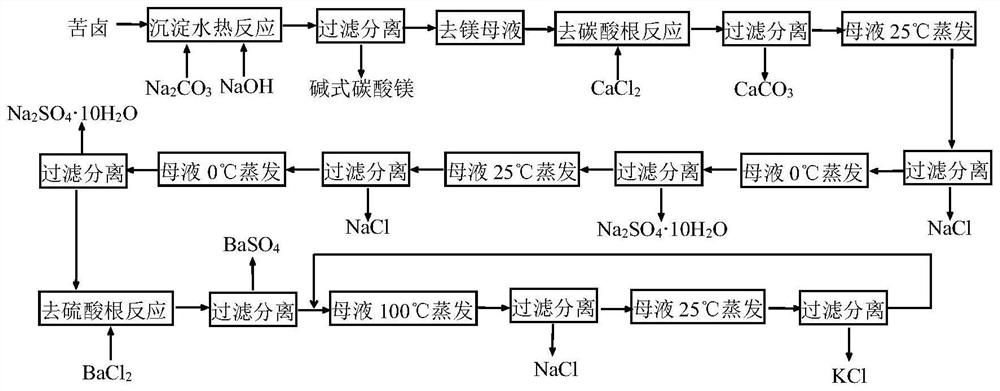

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: the specific operations are as follows:

[0045] 1. Preparation of Basic Magnesium Carbonate Crystals

[0046] The bittern raw material used in the present invention basically consists of: MgCl 2 : 165g·L -1 ;NaCl: 85g·L -1 ; KCl: 20g·L -1 ;MgSO 4 : 67.5g·L -1 .

[0047] (1) Take 250ml of bittern and place it in a 500ml three-neck round bottom flask, and place it in a water bath at 60°C, with a stirrer, add 2.5mol·L -1 Na 2 CO 3 and 3mol L -1 NaOH, guaranteed Mg 2+ :CO 3 2- :OH - The molar ratio of the mixture is 5:4.8:2. After stirring for 120s, it is allowed to stand still for 2.5h to obtain a slurry.

[0048] (2) Filter the slurry obtained in step (1) to obtain 533.5g filtrate and 52.8g solid, and wash the solid to neutral with deionized water, and the quality of the filtrate is composed of: Na + : 7.29%; K + : 0.49%; Cl - : 8.64%; SO 4 2- : 2.53%; CO 3 2- : 0.99%; H 2 O: 80.06%.

[0049] (3) Drying: Dry the solid product obtained i...

Embodiment 2

[0056] Embodiment 2: specific operation is as follows:

[0057] 1. Preparation of Basic Magnesium Carbonate Crystals

[0058] The bittern raw material used in the present invention basically consists of: MgCl 2 : 165g·L -1 ;NaCl: 85g·L -1 ; KCl: 20g·L -1 ;MgSO 4 : 67.5g·L -1 .

[0059] (1) Take 250ml of bittern and place it in a 500ml three-neck round bottom flask, and place it in a water bath at 60°C, with a stirrer, add 2.5mol·L -1 Na 2 CO 3 and 3mol L -1 NaOH, guaranteed Mg 2+ :CO 3 2- :OH - The molar ratio of the mixture is 5:4.8:1.9. After stirring for 120s, let stand for 2.5h to obtain a slurry.

[0060] (2) Filter the slurry obtained in step (1) to obtain 531.3g filtrate and 50.5g solid, and wash the solid to neutral with deionized water, and the quality of the filtrate is composed of: Na + : 7.25%; K + : 0.49%; Cl - :8.68%; SO 4 2- : 2.54%; CO 3 2- : 0.90%; H 2 O: 80.14%

[0061] (3) Drying: Dry the solid product obtained in step (2) at 100°C for...

Embodiment 3

[0068] Embodiment 3: specific operations are as follows:

[0069] 1. Preparation of Basic Magnesium Carbonate Crystals

[0070] The bittern raw material used in the present invention basically consists of: MgCl 2 : 165g·L -1 ;NaCl: 85g·L -1 ; KCl: 20g·L -1 ;MgSO 4 : 67.5g·L -1 .

[0071] (1) Take 250ml of bittern and place it in a 500ml three-neck round bottom flask, and place it in a water bath at 60°C, with a stirrer, add 2.5mol·L -1 Na 2 CO 3 and 3mol L -1 NaOH, guaranteed Mg 2+ :CO 3 2- :OH - The molar ratio of the mixture is 5:4.8:2.1. After stirring for 120s, it is allowed to stand still for 2.5h to obtain a slurry.

[0072] (2) Filter the slurry obtained in step (1) to obtain 538.7g filtrate and 52.8g solid, and wash the solid to neutral with deionized water, and the quality of the filtrate is composed of: Na + : 7.24%; K + : 0.48%; Cl - : 8.56%; SO 4 2- : 2.51%; CO 3 2- : 1.02%; H 2 O: 80.19%.

[0073] (3) Drying: Dry the solid product obtained i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com