Vanadium dioxide-based thermochromic composite film and preparation method thereof

A vanadium dioxide-based thermal and vanadium dioxide-based technology, which is applied in the field of vanadium dioxide-based thermochromic composite films and their preparation, can solve the problem of unsightly brown-yellow films, lack of regulation in the visible light band, and poor product promotion and promotion. impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

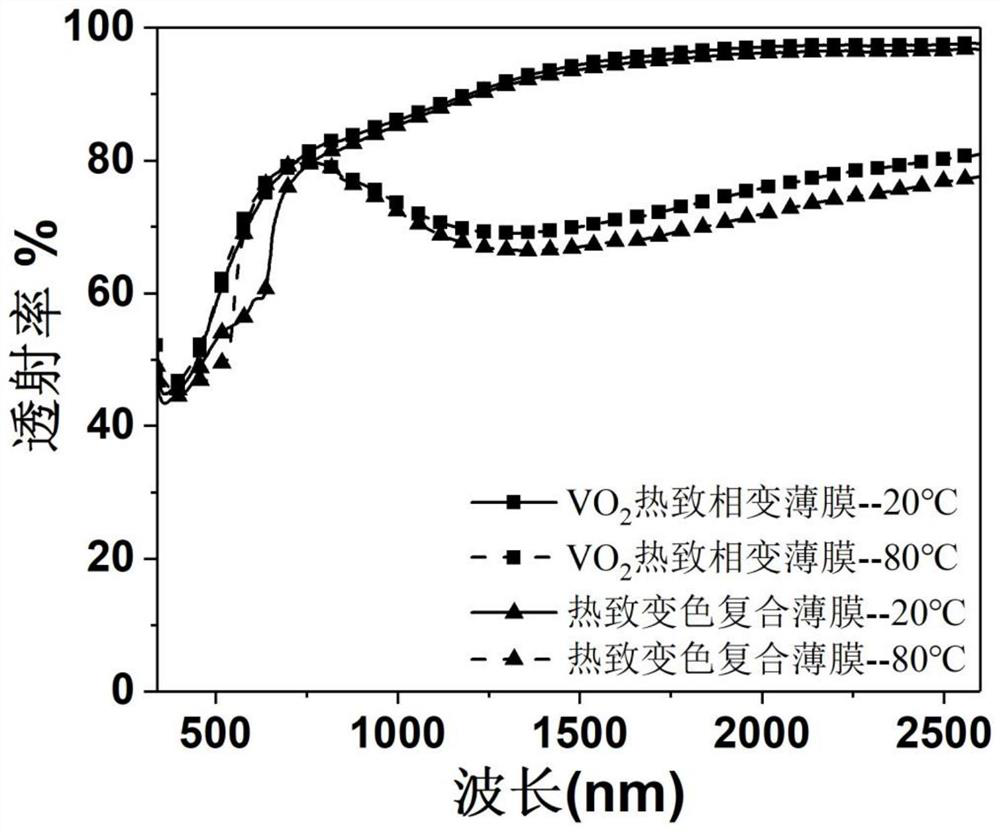

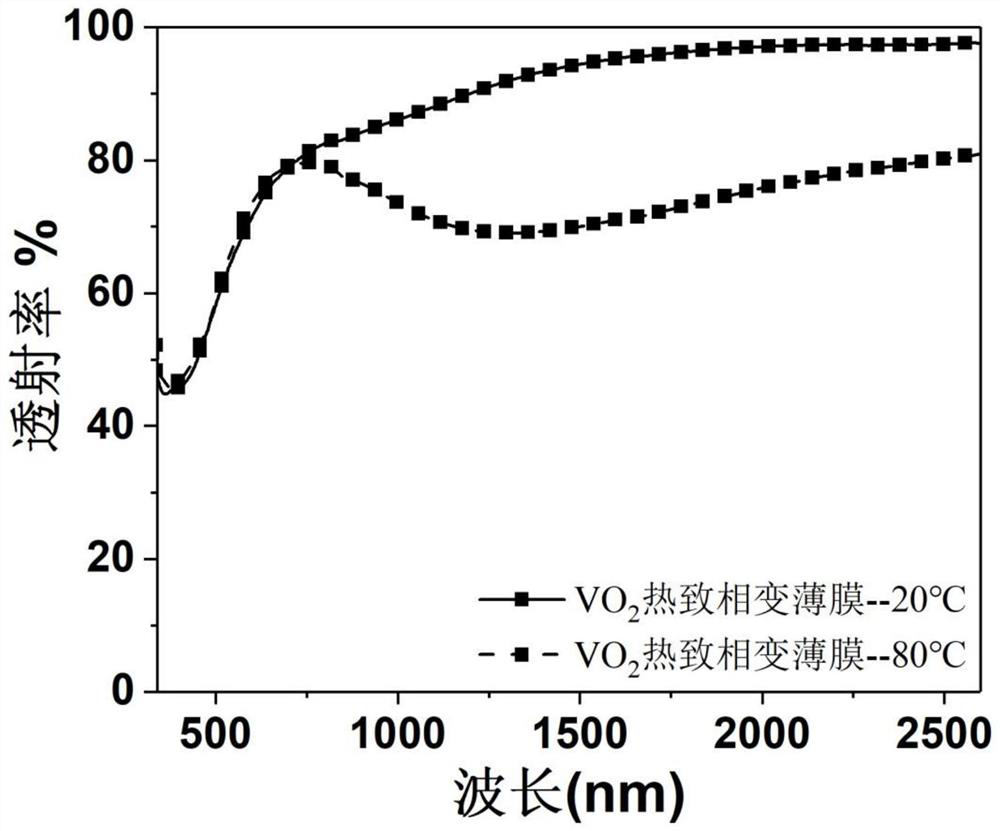

[0043] Weigh 0.05g of vanadium dioxide nanoparticles (33nm in particle size) and ultrasonically disperse them in 8g of ethanol to form a dispersion, then add 0.6g of polyvinyl butyral resin therein, form a uniform slurry by magnetic stirring, and use a roller The method of coating is to apply it on the substrate (glass, etc.), and place it at room temperature for 1 hour until it is cured (it can also be heated in an oven to accelerate its curing), and a vanadium dioxide-based thermally induced phase change film is obtained, which is brownish yellow. The thickness is 4 μm.

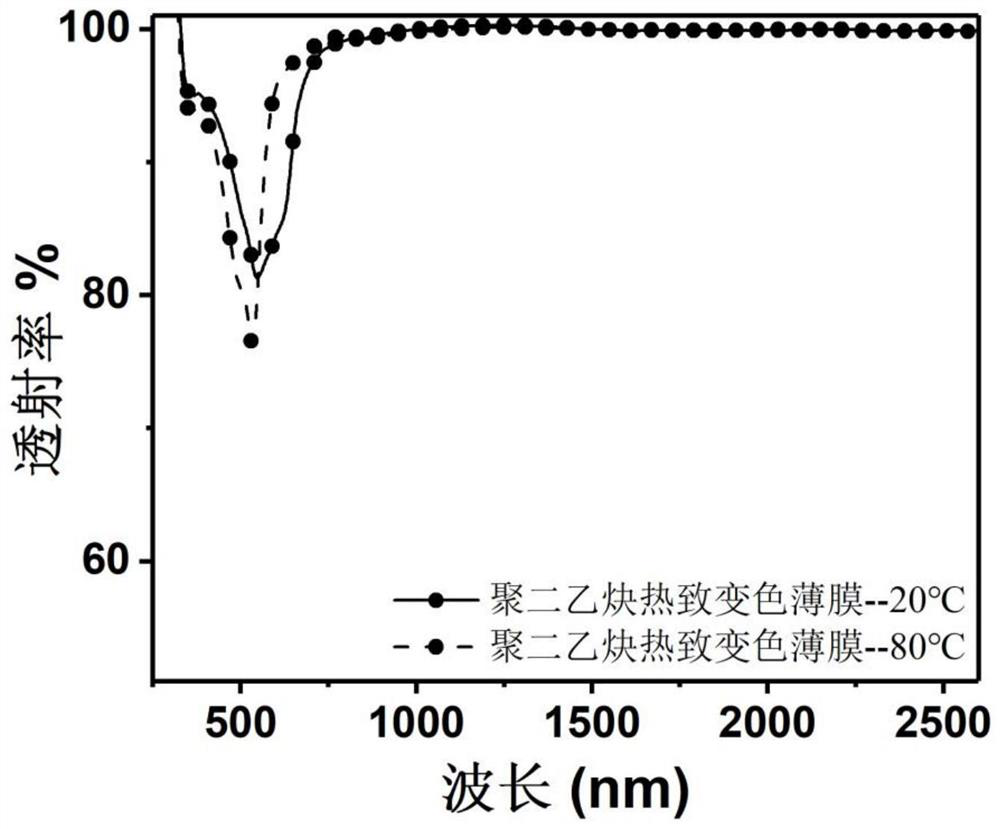

[0044] Add the monomer of polydiacetylene, a thermochromic polymer material, into chloroform solvent, and ultrasonically disperse for 2 hours to obtain a 2.5wt% transparent solution, which is then spin-coated (rotating speed is 2000r / min during spin-coating) onto On the pre-prepared vanadium dioxide-based thermochromic phase change film, after drying, induce polymerization by ultraviolet light with a wavele...

Embodiment 2

[0046] The vanadium dioxide-based thermally induced phase change film was prepared according to the method in Example 1, with a thickness of 4 μm.

[0047] Dissolve the monomer of the thermochromic polymer material polydiacetylene with chloroform, obtain a 1.5wt% transparent dispersion by ultrasonic, and spin-coat it (1000r / min during spin-coating) onto the pre-prepared On the vanadium dioxide-based thermochromic phase change film, after it is dried, it is induced to polymerize by ultraviolet light with a wavelength of 254nm for 30s to obtain a vanadium dioxide-based thermochromic composite film. After heating, the color development has the effect of changing from blue purple to red .

Embodiment 3

[0049] The vanadium dioxide-based thermally induced phase change film was prepared according to the method in Example 1, with a thickness of 4 μm.

[0050] Dissolve the monomer of the thermochromic polymer material polydiacetylene with chloroform, obtain a 2.5wt% transparent dispersion by ultrasonic, and spin-coat it (rotating speed is 500r / min during spin-coating) onto the pre-prepared On the vanadium dioxide-based thermochromic phase change film, after it is dried, it is irradiated with ultraviolet light with a wavelength of 254nm to induce polymerization for 5s to obtain a vanadium dioxide-based thermochromic composite film. After heating, the color development has the effect of changing from purple to red.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com