Cement reinforcing agent suitable for deepwater low-temperature environment, preparation method thereof and cement paste system

A cement enhancer, low-temperature environment technology, applied in chemical instruments and methods, drilling compositions, silicates, etc., can solve problems such as insufficiently meeting the needs of deep water cementing, and achieve improved operation efficiency and safety. Good fluidity and the effect of reducing waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

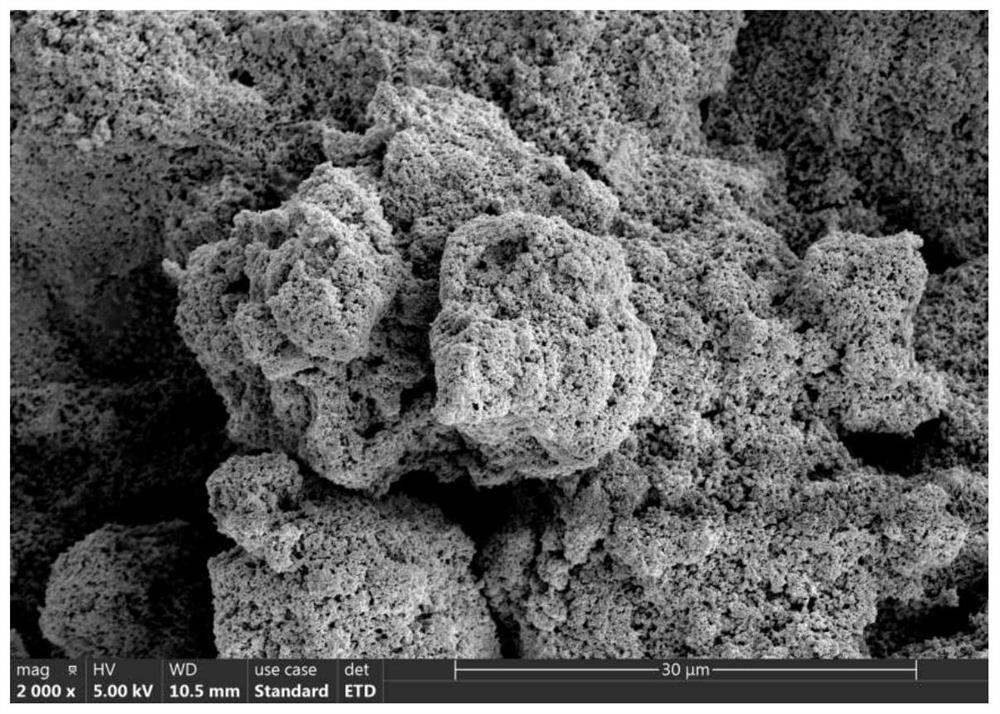

[0046] A cement reinforcing agent suitable for deep water and low temperature environment, prepared by the following preparation method:

[0047] S1: Na 2 SiO 3 9H 2 O dissolved in deionized water to make 1.0mol / L Na 2 SiO 3 solution; the Ca(NO 3 ) 2 4H 2 O dissolved in deionized water to make 1.0mol / L Ca(NO 3 ) 2 solution; KAl(SO 4 ) 2 12H 2 O was dissolved in deionized water to make 0.5mol / L KAl(SO 4 ) 2 solution;

[0048] S2: The prepared Ca(NO 3 ) 2 Add the solution into a three-necked flask, put the three-necked flask into a water bath at 60°C, insert a stirring rod and set the speed at 500r / min, and adjust the pH value of the solution to 11-13;

[0049] S3: Na 2 SiO 3 solution with KAl(SO 4 ) 2 The solution was added dropwise into a three-necked flask respectively, and the rate of addition was controlled at 2 drops / s. After 7 days of reaction, the pH of the mixed solution was regularly adjusted to be 13; the Na 2 SiO 3 solution, Ca(NO 3 ) 2 soluti...

Embodiment 2

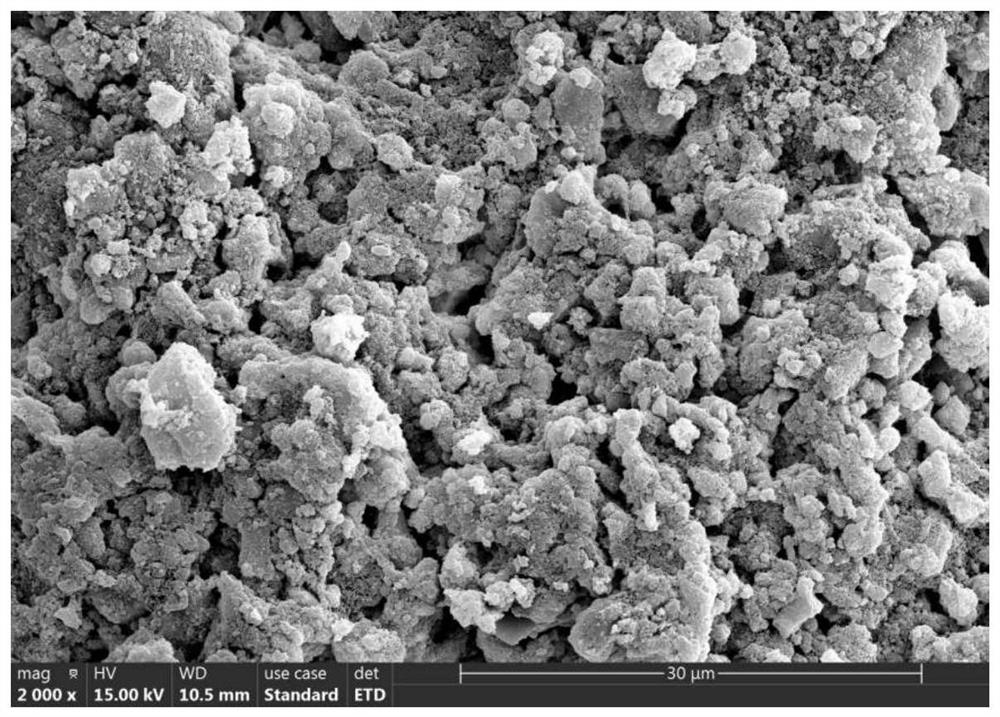

[0052] A cement slurry system, comprising the following components in parts by mass: 400 parts of G grade oil well cement, 12 parts of cement reinforcing agent in Example 1, 12 parts of fluid loss reducer, 4.8 parts of dispersant, defoamer 2 parts, 180 parts of mixing water.

[0053] The cement slurry system is prepared by the following preparation method: dry-mix the G-grade oil well cement and the cement reinforcing agent uniformly, and uniformly mix the liquid admixture (water loss reducer, dispersant, defoamer) with the slurry preparation water, Then prepare cement slurry with the obtained aqueous solution and dry-mixed powder according to GB / T 19139 "Test Methods for Oil Well Cement".

Embodiment 3

[0055] A cement slurry system, including the following components in parts by mass: 400 parts of G-grade oil well cement, 20 parts of cement reinforcing agent in Example 1, 12 parts of fluid loss reducer, 4.8 parts of dispersant, defoamer 2 parts, 182 parts of pulping water.

[0056] The cement slurry system is prepared by the following preparation method: dry-mix the G-grade oil well cement and the cement reinforcing agent uniformly, and uniformly mix the liquid admixture (water loss reducer, dispersant, defoamer) with the slurry preparation water, Then prepare cement slurry with the obtained aqueous solution and dry-mixed powder according to GB / T 19139 "Test Methods for Oil Well Cement".

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com