A kind of amino silicone oil emulsion and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

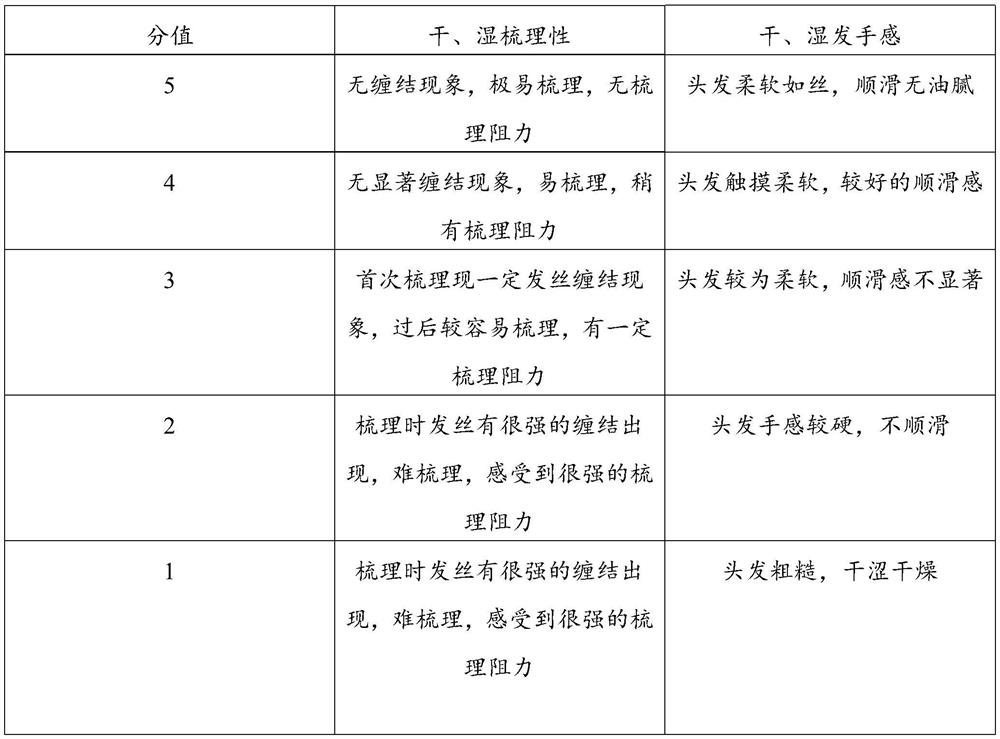

Image

Examples

Embodiment 1

[0028] A preparation method of amino silicone oil emulsion, comprising the following steps:

[0029] (1) Take amopolydimethylsiloxane, alcohol ether glycoside, glucose amide, ethylene glycol monobutyl ether, trifluoromethyl maleic anhydride, acetic acid and water;

[0030] (2) Add amodimethicone, alcohol ether glycoside, glucose amide and trifluoromethyl maleic anhydride into the reaction vessel, stir at 4000rpm at 60°C for 90min, then add ethylene glycol monobutyl Continue to stir the ether for 60 minutes, add water, and stir for 45 minutes at a speed of 500 rpm;

[0031] (3) Add acetic acid to the system obtained in step (2) to adjust the pH to 5.0-7.0, and stir evenly at a speed of 300 rpm to obtain the amino silicone oil emulsion;

[0032] Wherein, the amino silicone oil emulsion includes the following components in weight percentage: 35% of amodimethicone, 4% of alcohol ether glycoside, 2% of glucose amide, 4% of ethylene glycol monobutyl ether, trifluoroform Base malei...

Embodiment 2

[0034] A preparation method of amino silicone oil emulsion, comprising the following steps:

[0035] (1) Take amopolydimethylsiloxane, alcohol ether glycoside, glucose amide, ethylene glycol monobutyl ether, trifluoromethyl maleic anhydride, acetic acid and water;

[0036] (2) Add amodimethicone, alcohol ether glycoside, glucose amide and trifluoromethyl maleic anhydride into the reaction vessel, stir at 4000rpm at 60°C for 90min, then add ethylene glycol monobutyl Continue to stir the ether for 60 minutes, add water, and stir for 45 minutes at a speed of 500 rpm;

[0037] (3) Add acetic acid to the system obtained in step (2) to adjust the pH to 5.0-7.0, and stir evenly at a speed of 300 rpm to obtain the amino silicone oil emulsion;

[0038] Wherein, the amino silicone oil emulsion includes the following components in weight percentage: 35% of amodimethicone, 4.8% of alcohol ether glycoside, 1.2% of glucose amide, 4% of ethylene glycol monobutyl ether, trifluoromethyl Base...

Embodiment 3

[0040] A preparation method of amino silicone oil emulsion, comprising the following steps:

[0041] (1) Take amopolydimethylsiloxane, alcohol ether glycoside, glucose amide, ethylene glycol monobutyl ether, trifluoromethyl maleic anhydride, acetic acid and water;

[0042] (2) Add amodimethicone, alcohol ether glycoside, glucose amide and trifluoromethyl maleic anhydride into the reaction vessel, stir at 4000rpm at 60°C for 90min, then add ethylene glycol monobutyl Continue to stir the ether for 60 minutes, add water, and stir for 45 minutes at a speed of 500 rpm;

[0043] (3) Add acetic acid to the system obtained in step (2) to adjust the pH to 5.0-7.0, and stir evenly at a speed of 300 rpm to obtain the amino silicone oil emulsion;

[0044] Wherein, the amino silicone oil emulsion includes the following components in weight percentage: 35% of amodimethicone, 5% of alcohol ether glycoside, 1% of glucose amide, 4% of ethylene glycol monobutyl ether, trifluoroform Base malei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com