Rubber containing modified graphene

A graphene and rubber technology, applied in the field of rubber, can solve problems such as uneven dispersion, easy migration, discounted graphene anti-aging effect, etc., and achieve good anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

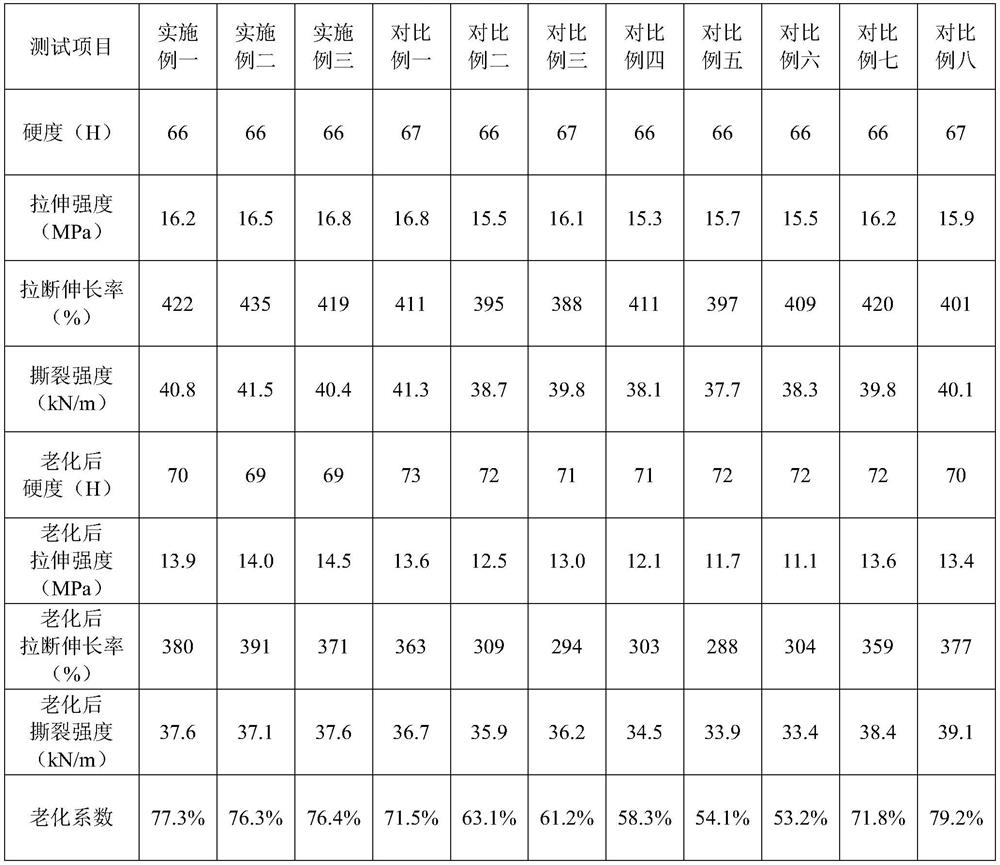

Examples

Embodiment 1

[0021] Embodiment one: a kind of rubber containing modified graphene, first weighed mass ratio is 5 parts of graphite, 25 parts of modifiers (12.5 parts of aminopropionamide, 12.5 parts of 1-(4-aminobenzene)-4- (4-methoxyphenyl)piperazine), fully mixed and ball milled, then added 30 parts of tert-butyl nitrite and 50 parts of toluene mixed ball milled, fully mixed and then washed to obtain modified graphene. Take by weighing 5 parts of the modified graphene, 100 parts of rubber (70 parts of styrene-butadiene rubber SBR1500, 10 parts of natural rubber, 20 parts of butadiene rubber BR9000), 60 parts of carbon black, 2 parts of zinc oxide, stearic acid 1.5 parts, 2 parts of sulfur, 1.5 parts of accelerator (CZ) are mixed to make rubber.

Embodiment 2

[0022] Embodiment two: a kind of rubber containing modified graphene, in parts by weight, first weighs 5 parts of graphite, 50 parts of modifying agents (25 parts of 4-aminobenzanilide, 25 parts of (4-(4 -aminobenzyl)piperazin-1-yl)ethanone), fully mixed and ball milled, then added 60 parts of tert-butyl nitrite and 150 parts of toluene mixed ball milled, mixed thoroughly and then washed to obtain modified graphene. Take by weighing 5 parts of the modified graphene, 100 parts of rubber (70 parts of styrene-butadiene rubber SBR1500, 10 parts of natural rubber, 20 parts of butadiene rubber BR9000), 60 parts of carbon black, 2 parts of zinc oxide, stearic acid 1.5 parts, 2 parts of sulfur, 1.5 parts of accelerator (CZ) are mixed to make rubber.

Embodiment 3

[0023] Embodiment three: a kind of rubber containing modified graphene, in parts by weight, first weighs 5 parts of graphite, 50 parts of modifying agents (25 parts of 2-amino-N-cyclohexyl-N-methylbenzene Amine, 25 parts of (4-aminobenzene)-4-(4-methoxyphenyl) piperazine), fully mixed and ball milled, then added 60 parts of tert-butyl nitrite and 200 parts of acetone, mixed and ball milled, after fully mixed After washing, the modified graphene is obtained. Take by weighing 5 parts of the modified graphene, 100 parts of rubber (70 parts of styrene-butadiene rubber SBR1500, 10 parts of natural rubber, 20 parts of butadiene rubber BR9000), 60 parts of carbon black, 2 parts of zinc oxide, stearic acid 1.5 parts, 2 parts of sulfur, 1.5 parts of accelerator (CZ) are mixed to make rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com