Wide-frequency-band terahertz wave-absorbing material and preparation method thereof

A wave absorbing material and terahertz technology, applied in the field of terahertz wave absorbing materials, can solve the problems of the decline of terahertz wave absorption performance index, the heavy weight of terahertz wave absorbing materials, and the sluggish high-frequency response of electromagnetic fields, and achieve a good free space. The effect of impedance matching, good absorption performance and fast high frequency response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

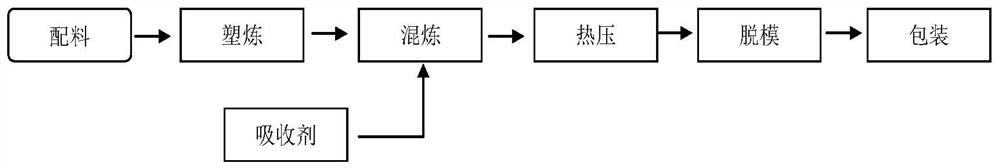

[0038] according to figure 1 The process flow shown prepares a terahertz absorbing material with a size of 300mm×300mm and a thickness of 0.85mm. The specific process flow is as follows:

[0039] Ingredients: Weigh raw materials by mass parts: 1 part of antioxidant KY-405, 24.2 parts of absorbent (acetylene carbon black), 1 part of stearic acid, 100 parts of polyurethane gum, coupling agent (silane coupling agent A -151) 3 parts, vulcanizing agent (2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane) 3 parts, crosslinking aid (triallyl cyanurate TAC) 2 servings.

[0040] Mastication: Masticate 100 parts of raw polyurethane rubber, make it wrap the front roller, make triangular bags several times, add stearic acid, and masticate for 15 minutes in total.

[0041]Mixing: At room temperature, turn on the cooling water, first adjust the roller distance to (2.5±0.5)mm, and gradually add the absorbent acetylene carbon black to the plasticized polyurethane raw rubber until all the absorben...

Embodiment 2

[0049] according to figure 1 The process flow shown prepares a terahertz absorbing material with a size of 300mm×300mm and a thickness of 1.21mm. The specific process flow is as follows:

[0050] Ingredients: Weigh raw materials by weight: 1 part of antioxidant KY-405, 26.6 parts of absorbent (acetylene carbon black), 1 part of stearic acid, 100 parts of polyurethane gum, coupling agent (silane coupling agent A -151) 3 parts, vulcanizing agent (2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane) 3 parts, crosslinking aid (triallyl cyanurate TAC) 2 servings.

[0051] Mastication: Masticate 100 parts of raw polyurethane rubber, make it wrap the front roller, make triangular bags several times, add stearic acid, and masticate for 15 minutes in total.

[0052] Mixing: At room temperature, turn on the cooling water, first adjust the roller distance to (2.5±0.5)mm, and gradually add the absorbent acetylene carbon black to the plasticized polyurethane raw rubber until all the absorbent a...

Embodiment 3

[0060] according to figure 1 The process flow shown prepares a terahertz absorbing material with a size of 300mm×300mm and a thickness of 0.65mm. The specific process flow is as follows:

[0061] Ingredients: Weigh raw materials by mass parts: 1 part of antioxidant KY-405, 19.4 parts of absorbent (mixing carbon black and graphene at a mass ratio of 1:1), 1 part of stearic acid, 100 parts of polyurethane gum, 3 parts of coupling agent (silane coupling agent A-151), 3 parts of vulcanizing agent (2,5-dimethyl-2,5-bis(tert-butyl peroxide) hexane), 3 parts of crosslinking aid (three Allyl cyanurate (TAC) 2 parts.

[0062] Mastication: Masticate 100 parts of raw polyurethane rubber, make it wrap the front roller, make triangular bags several times, add stearic acid, and masticate for 15 minutes in total.

[0063] Mixing: At room temperature, turn on the cooling water, first adjust the roller distance to (2.5±0.5)mm, and gradually add the absorbent acetylene carbon black to the pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com