Straw bale loosening and drying machine

A straw bale and dryer technology, applied in dryers, drying, heating devices and other directions, can solve the problems of low thermal efficiency, insufficient fire, and difficult to burn thoroughly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

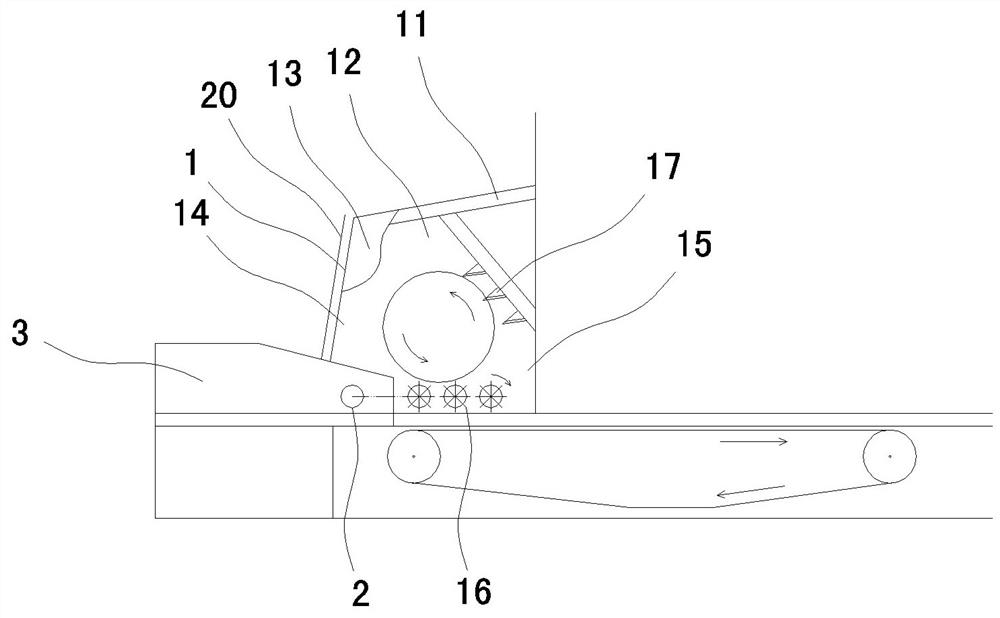

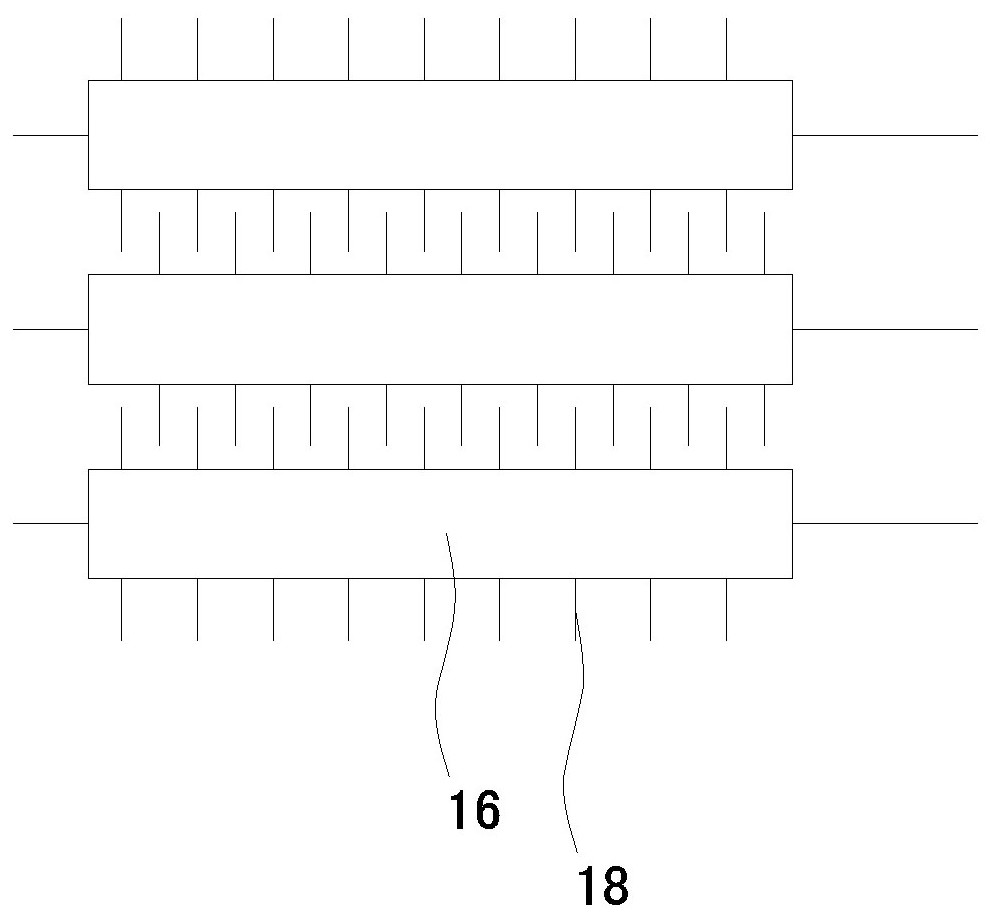

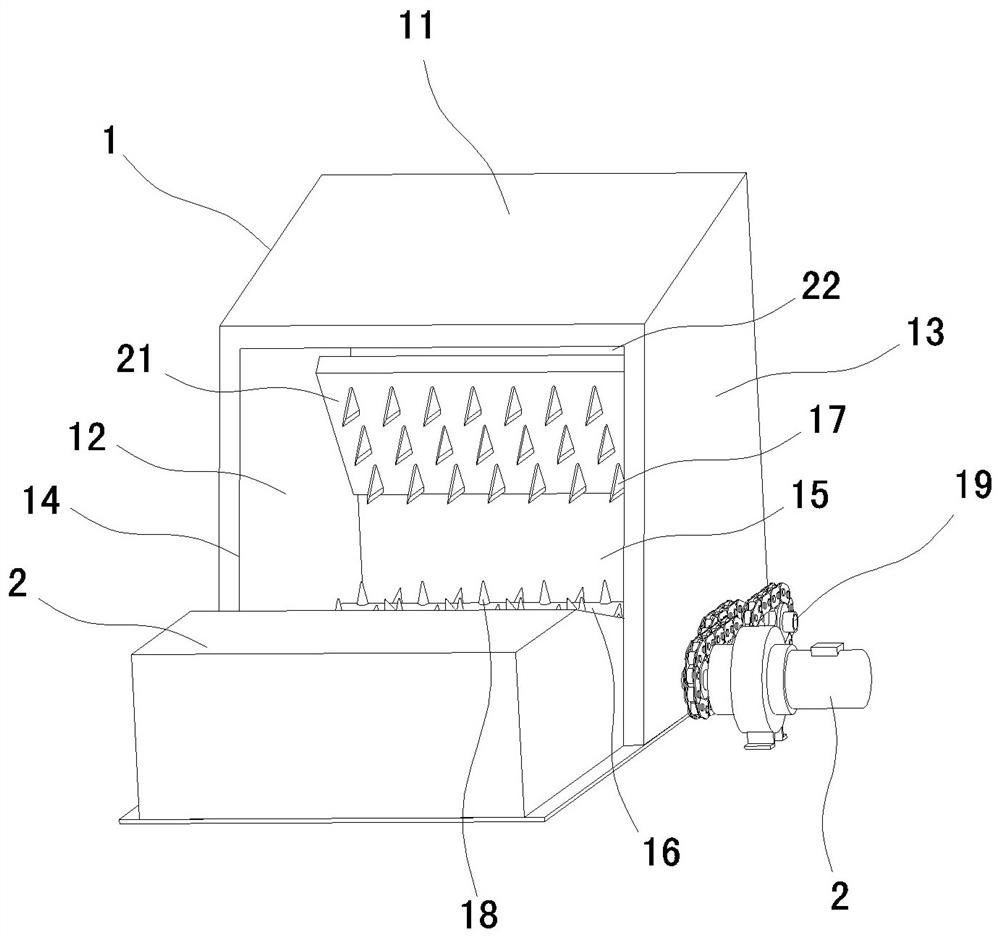

[0013] like figure 1 As shown, it includes a housing 1 and a geared motor 2. The housing 1 includes a top wall 11, a left wall 12 and a right wall 13. The front part of the housing 1 is provided with a The bale inlet 14 between the front of the housing 1, the rear and the bottom are provided with the bulk material outlet 15 between the bottom and the rear of the left wall 12 and the right wall 13, the lower part of the bale inlet 14 at the front of the housing 1 is provided with The packing platform 3, the rear part of the packing platform 3 is provided with at least two rolling rollers 16 installed on the left wall 12 and the right wall 13 of the housing 1 respectively at the left and right ends from the front to the rear, and the rolling rollers 16 are the same The shaft ends in the direction extend out of the housing 1 and are connected to the reduction motor 2 through a chain transmission device. In the housing 1 from top to bottom, there are several rolling rollers 16 loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com