Design method of S/C dual-band multilayer tunable frequency selective surface

A frequency-selective surface and design method technology, applied to antennas, electrical components, etc., can solve problems such as single operating frequency and poor low-frequency absorbing performance, and achieve high absorbing strength, thin overall thickness, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: The design method of a kind of S / C dual-band multi-layer tunable type frequency selective surface in the present embodiment is carried out according to the following steps:

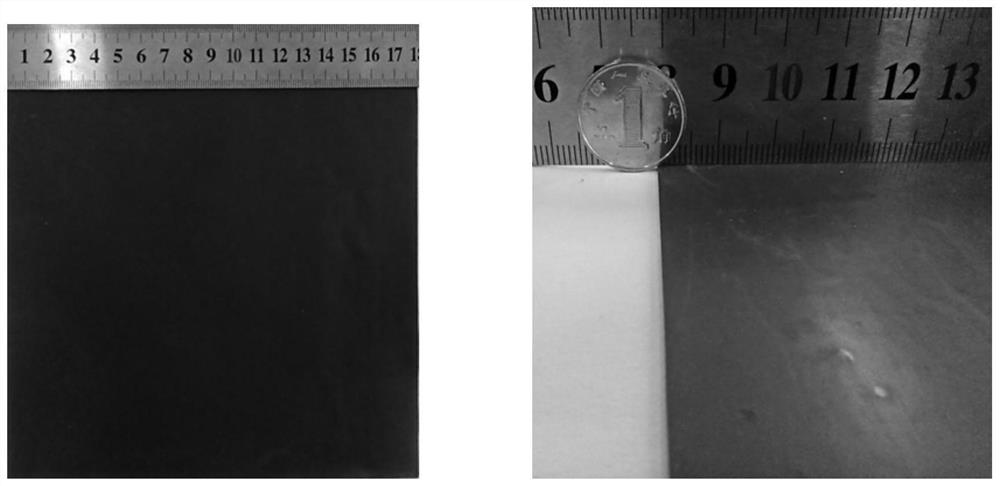

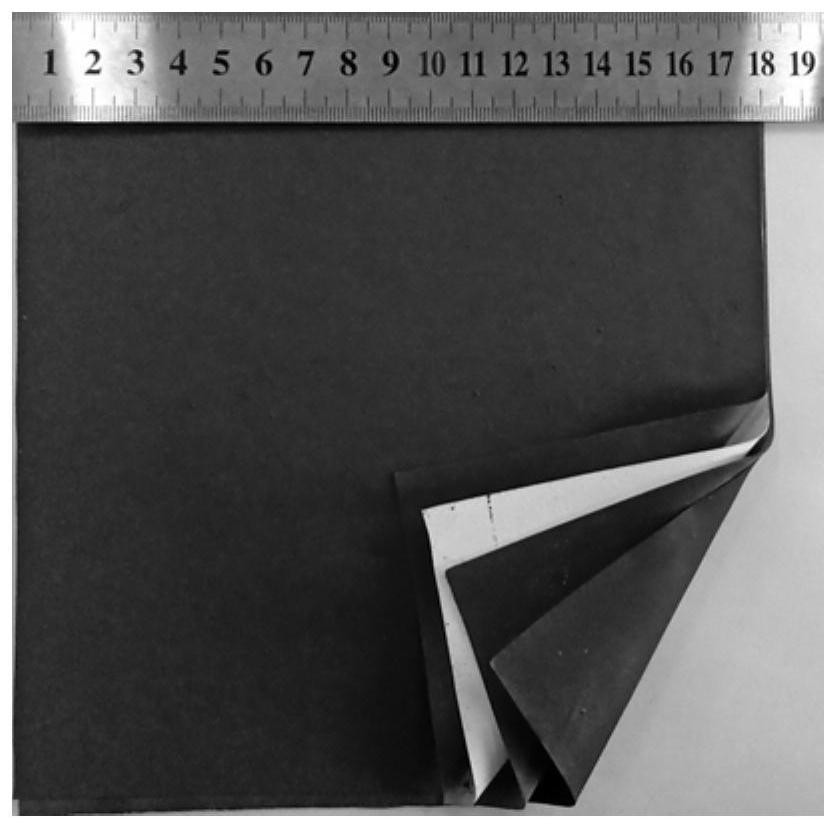

[0035] Step 1. Add 4.39g of polyvinyl butyral (PVB) powder into 50ml of absolute ethanol, stir at room temperature with a magnetic stirrer until the solution is transparent (it takes about 10h), to obtain an ethanol solution of PVB, and then add different The amount and type of powder, as well as 5ml tributyl phosphate and 3ml dibutyl phthalate, and then stir in a vacuum mixer at a speed of 300rpm for 20min to obtain a suspension, and then pour the suspension evenly on the casting machine , set the scraper speed to 10mm / s, set the height to 1mm, obtain a film by casting method, and let it dry naturally for 24 hours, dry or dry naturally at room temperature to obtain multiple films;

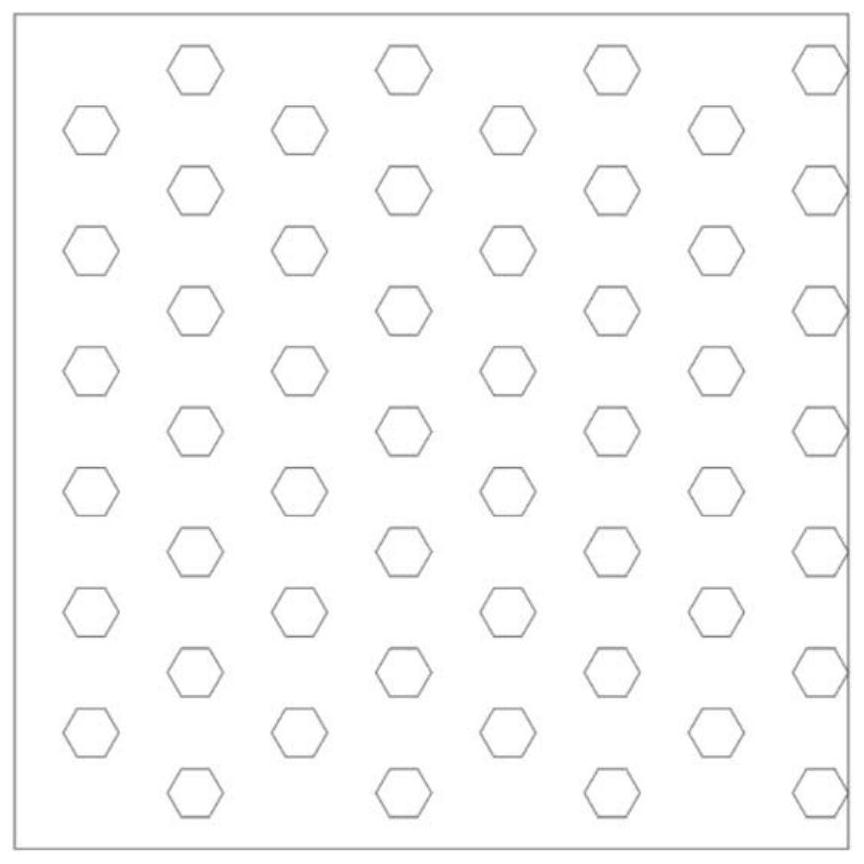

[0036] Step 2. Place the multiple films obtained in Step 1 in a laser engraving machine, and use AutoC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com