Non-grain oriented electrical steel and method for manufacturing same

A technology of grain-oriented electrical steel sheet and manufacturing method, applied in manufacturing tools, circuits, electrical components, etc., can solve the problems of iron loss, magnetic flux density decay, rapid magnetic decay, application limitation, etc., to ensure magnetic flux density and yield strength. Characteristics, crystal growth promotion, low iron loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

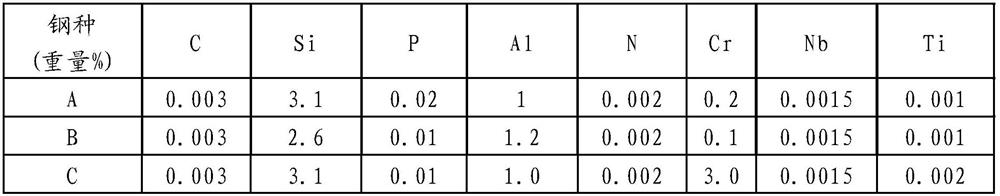

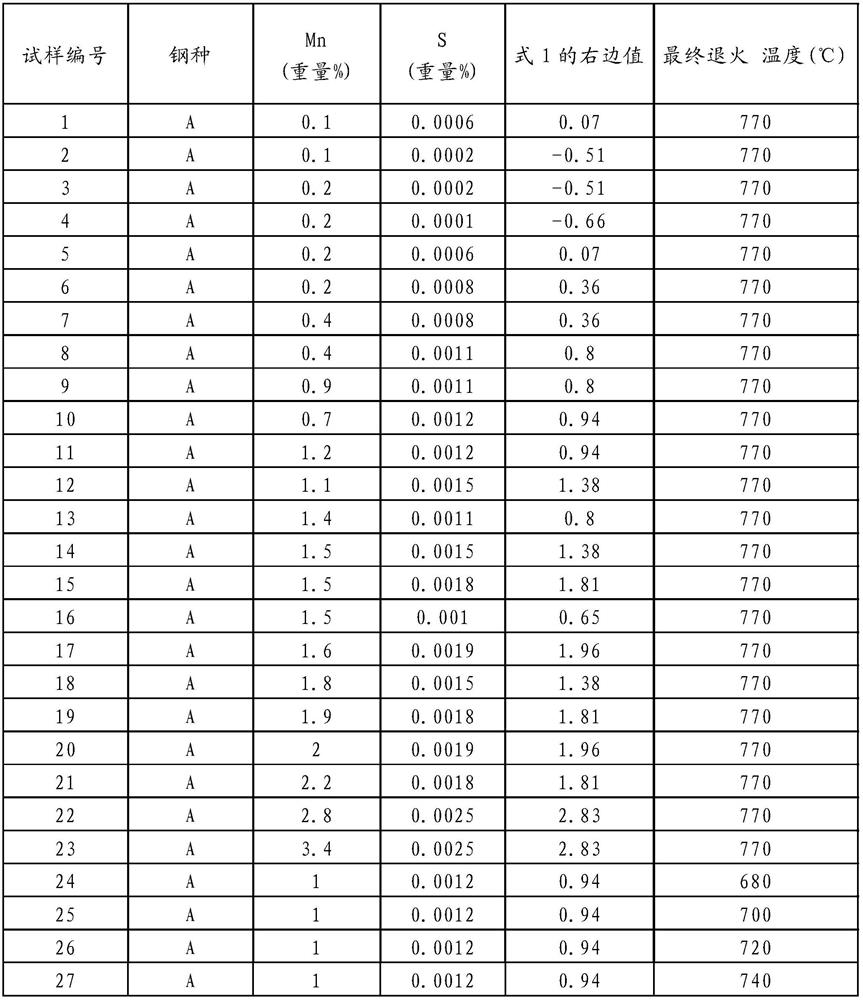

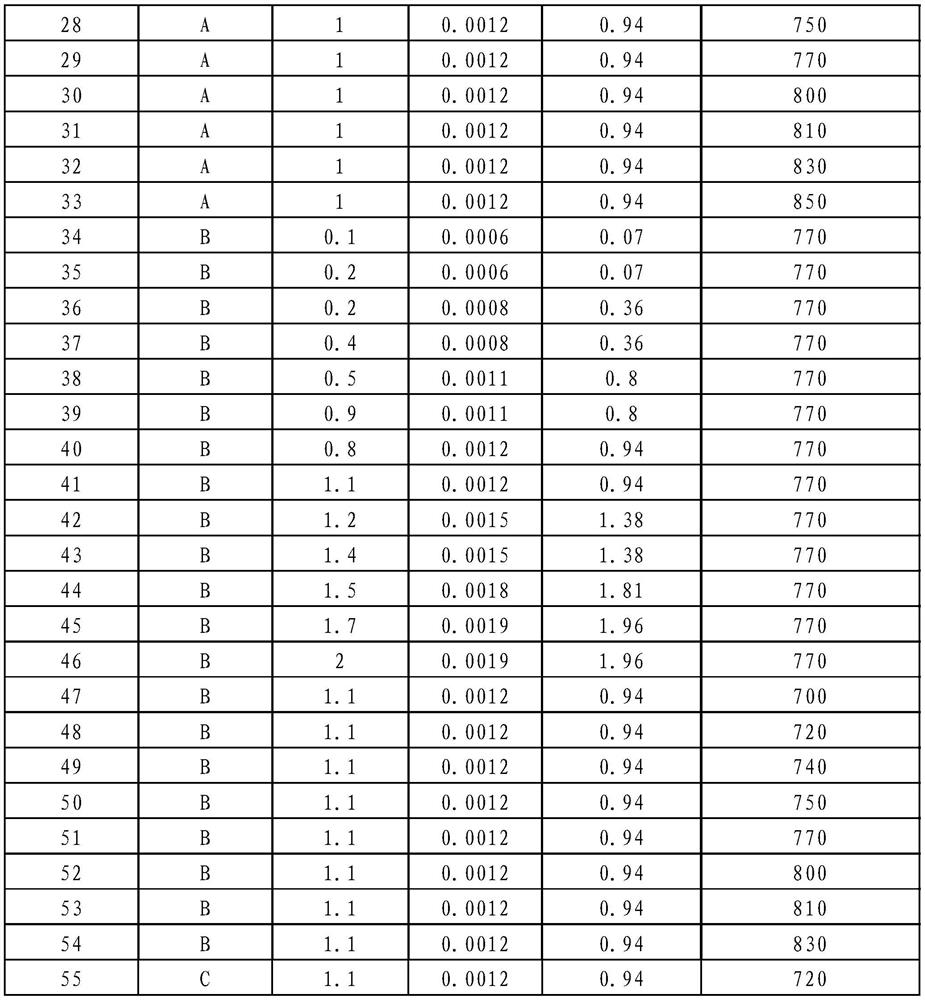

[0088] A slab containing the components of Table 1 and Table 2 below and the balance of Fe and unavoidable impurities in % by weight was produced. The slab was reheated at 1130° C. and then hot-rolled to 2.0 mm to produce a hot-rolled sheet. Each produced hot-rolled sheet was coiled at 620° C., then cooled in air, and hot-rolled sheet annealing was performed at 1020° C. for 2 minutes. Next, after pickling the hot-rolled sheet, cold rolling was implemented so that the thickness might become 0.25 mm. Next, under the atmosphere conditions of 20% by volume of hydrogen and 80% by volume of nitrogen, the cold-rolled sheet was subjected to final annealing for 1 minute at the temperature shown in Table 2 below, and then the magnetic and mechanical properties were analyzed and summarized in the table below 3 in. In the properties before stress relief annealing, for the yield strength, a tensile test was performed after preparing a KS13B specification sample, and the yield strength wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com