Wear-resistant combined all-ceramic false tooth and processing technology

A processing technology and combined technology, applied in the direction of dentures, etc., can solve the problems of high cost, cumbersome replacement process, and short service life of all-ceramic dentures, and achieve the effects of reducing maintenance costs, simplifying the replacement process, and speeding up the connection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following is attached Figure 1-4 The application is described in further detail.

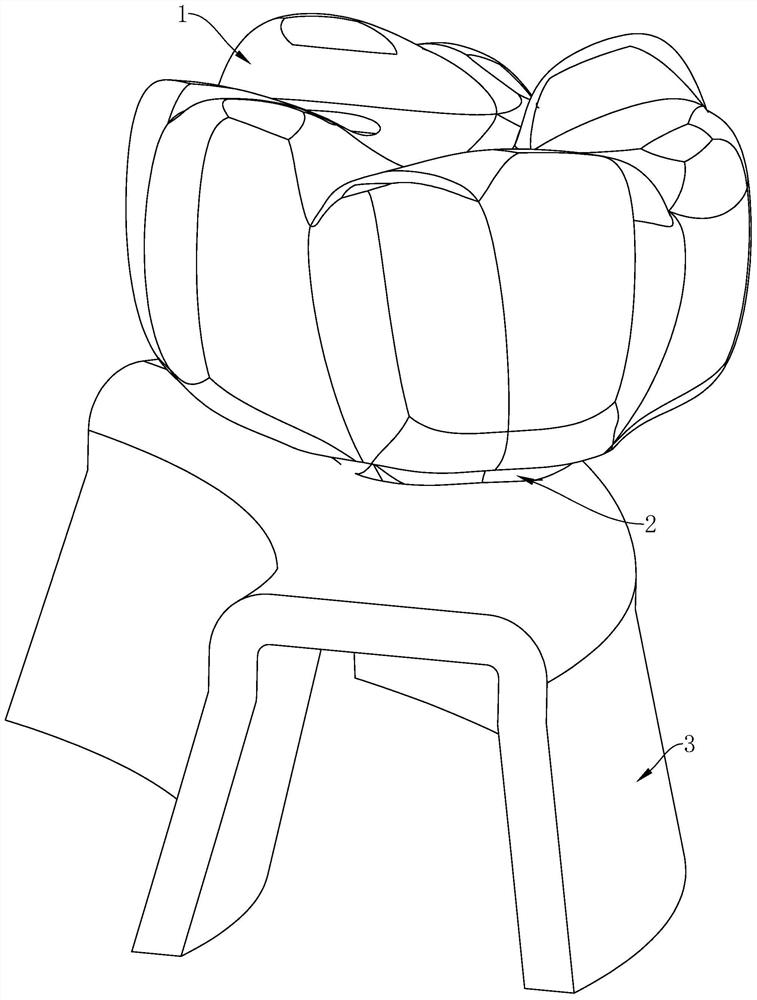

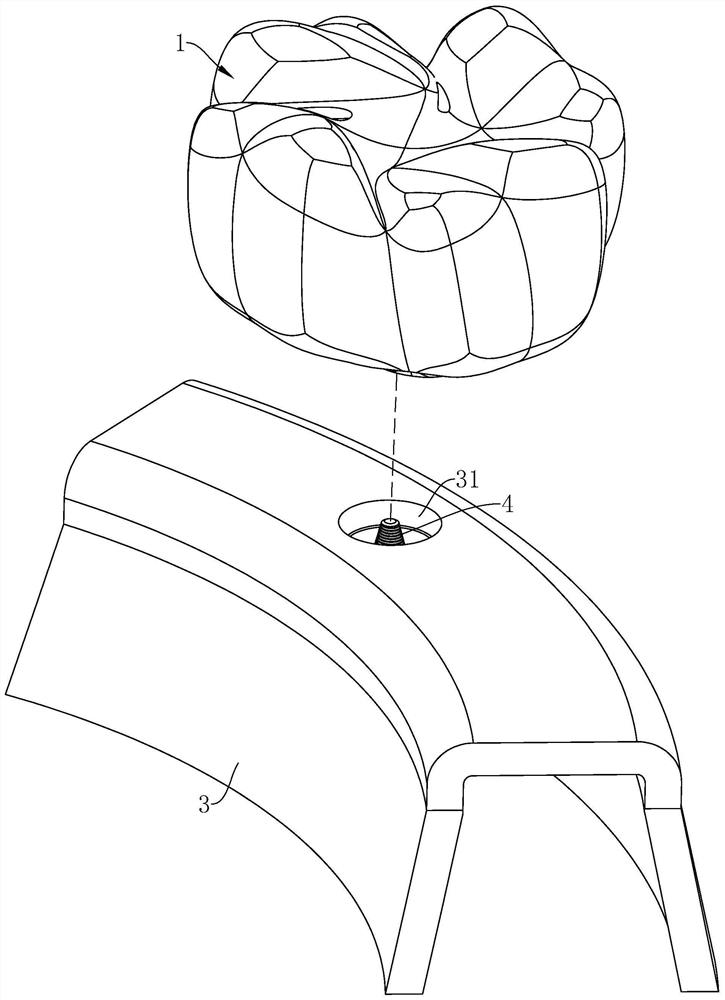

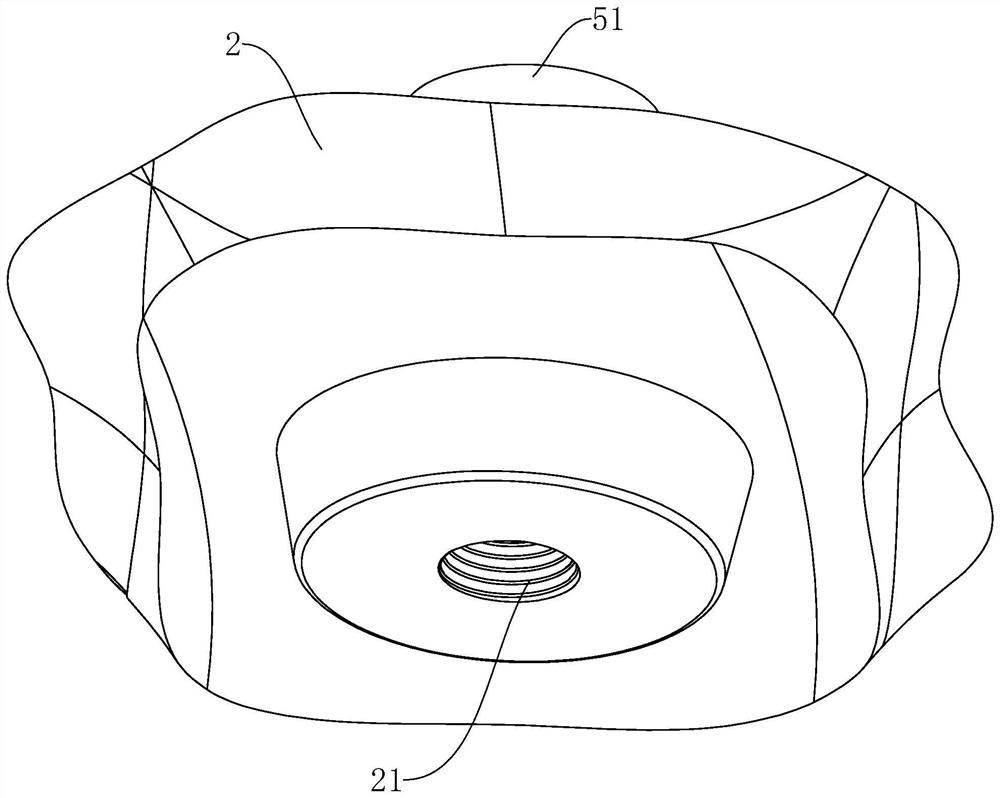

[0048] The embodiment of the present application discloses a wear-resistant combined all-ceramic denture, referring to figure 1 and figure 2 , the wear-resistant combined all-ceramic denture includes a crown crown 1, a tooth center 2 and a gingival seat 3, the gingival seat 3 is a U-shaped shell structure and is used for snap-fitting with the gingiva in the human oral cavity, and the gingival seat 3 is away from the gingiva The curved surface of the sinker groove 31 is provided with a sinking groove 31, and a medical screw 4 is pre-embedded in the groove bottom of the sinking groove 31. The medical screw 4 is screwed into the tooth center seat 2 and threaded with the tooth center seat 2, and the tooth center seat 2 is threaded with the medical screw 4. One end of the connection is plugged and fitted with the sinker 31 , and the end of the interdental base 2 away from the gum base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com