Dry-process stone-like kerb and preparation method thereof

A curb stone and imitation stone technology, applied in the direction of gutter/curb stone, roads, roads, etc., can solve the problems of hindered application of natural stone curb stone, affecting the quality of pavement engineering, not being recognized by the market, etc., to achieve large-scale manufacturing , The effect of reducing construction cost and long service life

Pending Publication Date: 2021-08-03

合肥格林工程材料有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Curb stones are divided into cement concrete curb stones and natural stone curb stones according to their materials. At present, due to the impact of environmental protection, the application of natural stone curb stones is hindered

Due to the low strength and poor frost resistance of traditional cement concrete curbs, it is easy to peel off and fall off due to the influence of sunlight and climate, which affects the engineering quality of the entire road surface, and is increasingly not recognized by the market

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0032] A dry imitation stone curb comprises the following components in proportion by weight:

[0033] 12% cement, 80% tailings sand, 1.1‰ binder

Embodiment 2

[0035] A dry imitation stone curb comprises the following components in proportion by weight:

[0036] 20% cement, 75% tailings sand, 1.5‰ binder

Embodiment 3

[0038] A dry imitation stone curb comprises the following components in proportion by weight:

[0039] 25% cement, 72% tailings sand, 1.9‰ binder

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

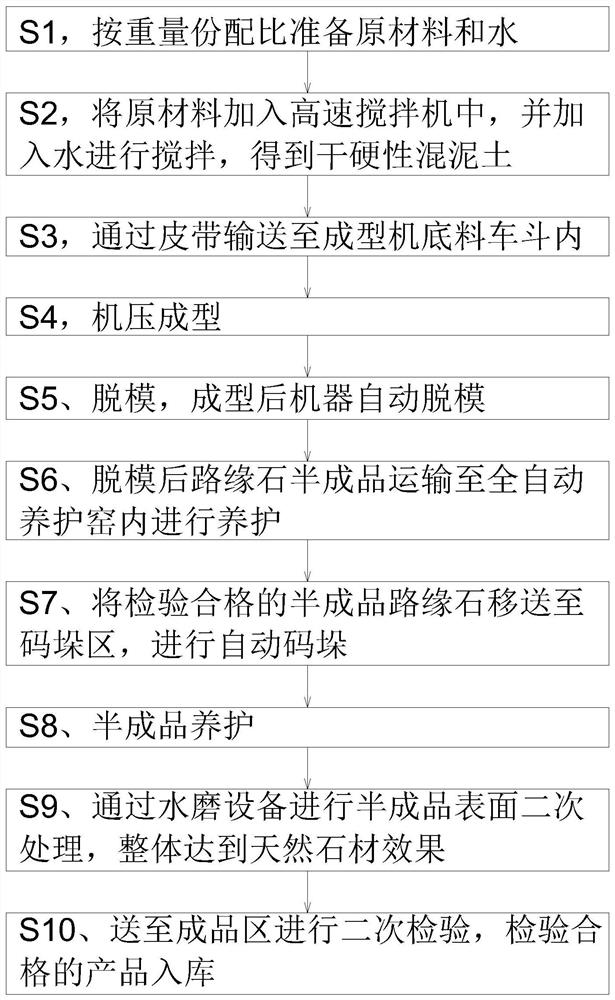

The invention discloses a dry-process stone-like curb which comprises the following components in percentage by weight: 10-30% of cement, 70-90% of tailing sand and 0.1-0.2% of an adhesive, and a preparation method comprises the following steps: S1, preparing raw materials and water in percentage by weight; s2, adding the raw materials into a high-speed stirrer, adding water for stirring, and obtaining dry hard concrete; s3, conveying the materials into a forming machine bottom material car hopper through a belt; s4, mechanical pressing molding; s5, demolding: automatically demolding by a machine after molding; s6, after demolding, transporting the kerb semi-finished product into a full-automatic curing kiln for curing; s7, transferring the qualified semi-finished kerb to a stacking area, and stacking the qualified semi-finished kerb; s8, maintaining a semi-finished product; s9, carrying out secondary treatment on the surface of the semi-finished product through water milling equipment to integrally achieve a natural stone effect; and S10, conveying the product to a finished product area for secondary inspection, and warehousing the qualified products. The invention relates to the technical field of kerbs. According to the invention, the problems of peeling, chipping and poor quality of the traditional curb are solved.

Description

technical field [0001] The invention relates to the technical field of curbstones, in particular to a dry-process imitation stone curbstone and a preparation method thereof. Background technique [0002] Curb stone is the abbreviation of the edge stones on both sides of the road surface, usually a strip structure between the road surface and the road shoulder on both sides of the road. Curb stones are usually laid on both sides of the road surface to separate the road surface from other structures. For example, a curb stone higher than the road surface can be provided between the sidewalk and the motorway. [0003] Curb stones are divided into cement concrete curb stones and natural stone curb stones according to their materials. At present, due to the impact of environmental protection, the application of natural stone curb stones is hindered. Due to its low strength and poor frost resistance, traditional cement concrete curbs are easily peeled and broken by sunlight and c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/00C04B18/12E01C11/22C04B111/54

CPCC04B28/00C04B18/12E01C11/221E01C11/222C04B2111/542Y02W30/91

Inventor 程彬王国庆张利国

Owner 合肥格林工程材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com