Application of cleaning fluid after chemical mechanical polishing

A chemical-mechanical and cleaning fluid technology, applied in the field of cleaning fluid after chemical mechanical polishing, can solve problems such as corrosion and poor biocompatibility, and achieve the effects of low corrosion rate, good stability and strong cleaning ability

Active Publication Date: 2021-08-03

SHANGHAI SINYANG SEMICON MATERIALS

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The technical problem to be solved by the present invention is to provide an application of cleaning solution after chemical mechanical polishing in order to overcome the defects of existing cleaning solutions such as cleaning, corrosion, timeliness, and poor biocompatibility.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

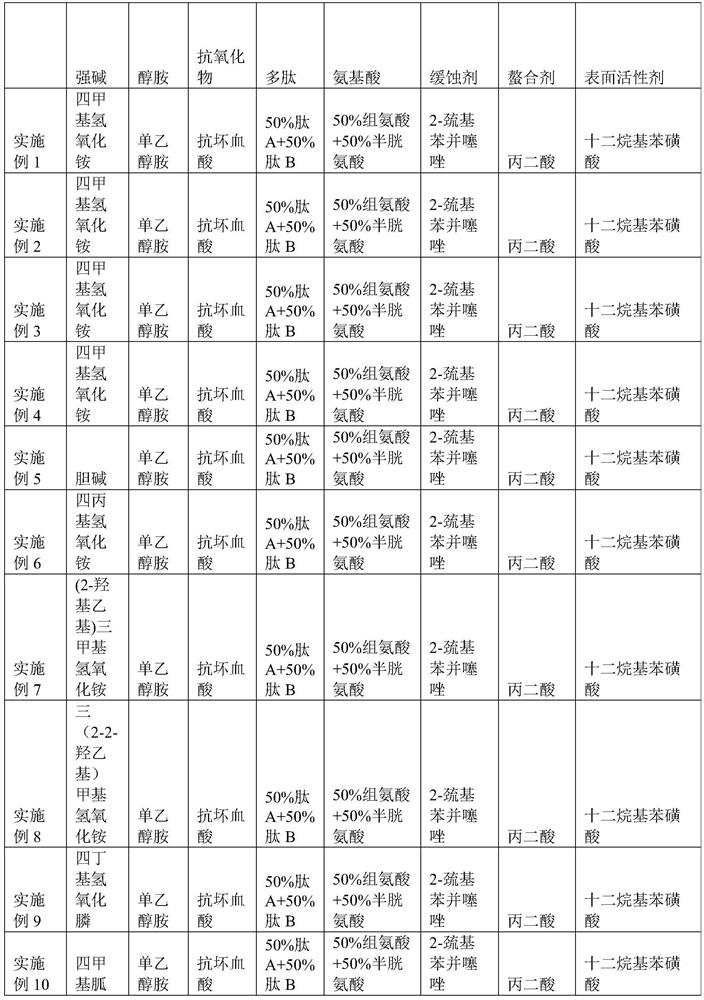

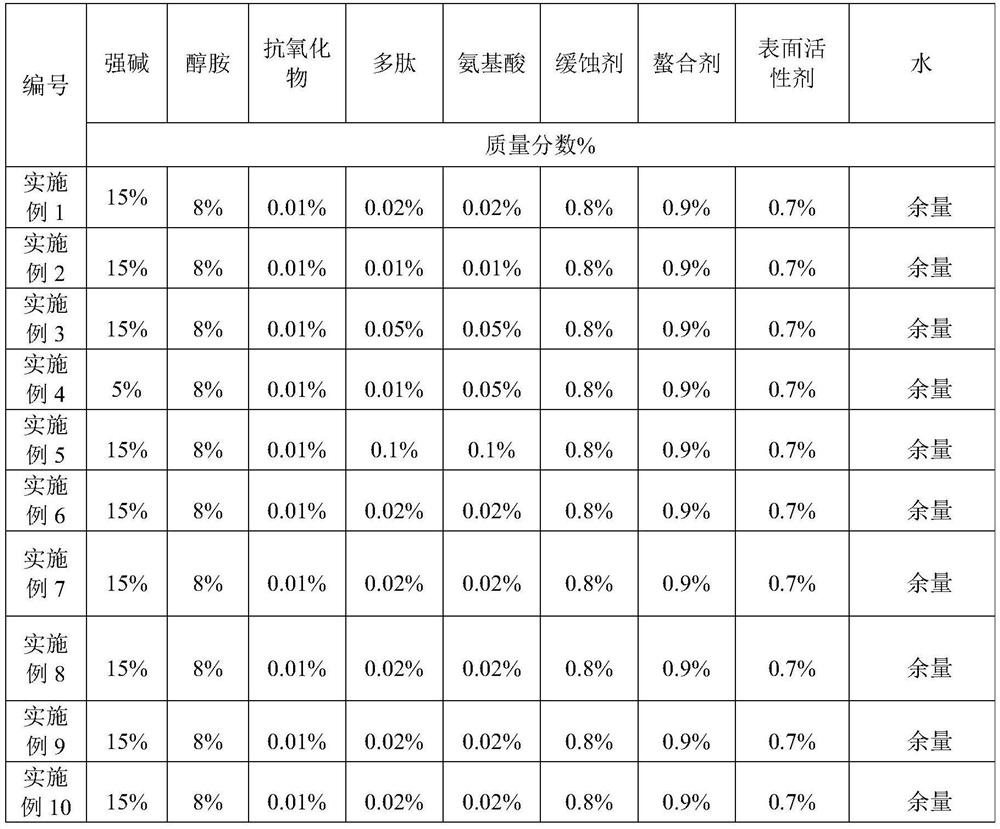

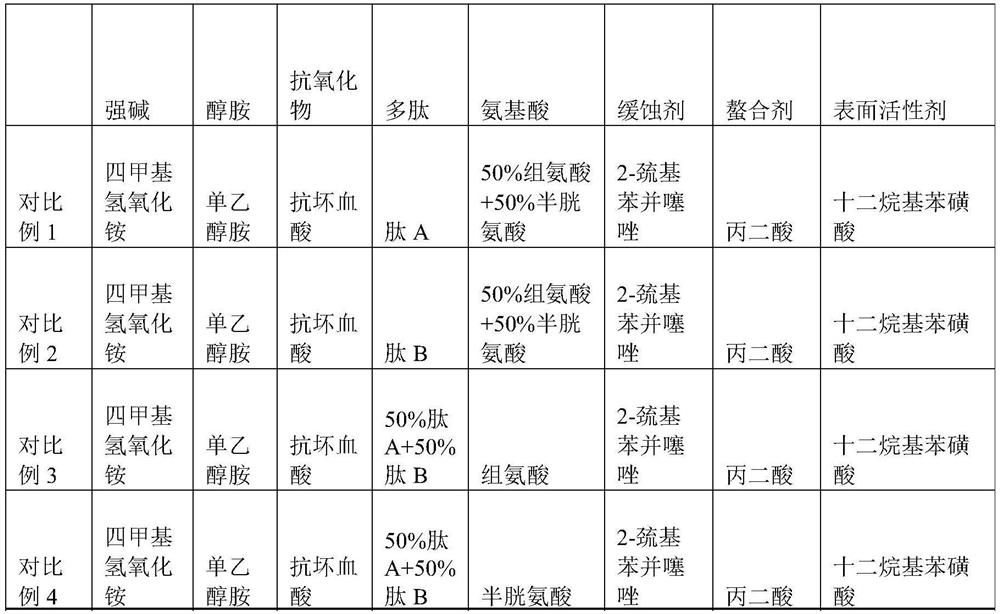

[0049] In the following examples and comparative examples, the preparation method of the cleaning solution includes the following steps: mixing the corresponding raw materials.

[0050] In the following examples, those that do not limit the specific operating temperature all refer to carrying out at room temperature.

[0051] Peptide A: reduced glutathione; peptide B: oxidized glutathione;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses an application of a cleaning fluid after chemical mechanical polishing. The invention specifically discloses the application of the cleaning fluid to cleaning of a semiconductor device after chemical mechanical polishing. The raw materials of the cleaning fluid comprise the following components by mass: 0.01%-25% of strong base, 0.01%-30% of alcohol amine, 0.001%-1% of antioxidants, 0.01%-0.1% of polypeptide, 0.01%-0.1% of amino acid, 0.01%-10% of corrosion inhibitors, 0.01%-10% of chelating agents, 0.01%-5% of surfactants and 28.9%-89.9% of water, and the sum of the mass fractions of all the components is 100%, wherein the amino acid is a combination of histidine and cysteine, and the polypeptide is a combination of reduced glutathione (peptide A) and oxidized glutathione (peptide B). The cleaning fluid is higher in cleaning capacity, lower in corrosion rate, higher in BTA removal capacity and higher in stability, and the effects of cleaning, corrosion inhibition and BTA removal can be achieved at the same time.

Description

technical field [0001] The invention relates to the application of cleaning liquid after chemical mechanical polishing. Background technique [0002] Metal materials such as copper, aluminum, tungsten, etc. are commonly used wire materials in integrated circuits. Chemical Mechanical Polishing (CMP) has emerged as the primary technique for wafer planarization during device fabrication. Metal chemical mechanical polishing fluids usually contain abrasive particles, complexing agents, metal corrosion inhibitors, oxidants, and the like. The abrasive particles are mainly silicon dioxide, aluminum oxide, aluminum-doped or aluminum-covered silicon dioxide, ceria, titanium dioxide, polymer abrasive particles, etc. After the metal CMP process, the surface of the wafer will be polluted by metal ions and abrasive particles in the polishing solution, which will affect the electrical characteristics of the semiconductor and the reliability of the device. The residue of these metal ions...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23G1/18C23G1/20

CPCC23G1/18C23G1/20

Inventor 王溯马丽史筱超李健华王亮

Owner SHANGHAI SINYANG SEMICON MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com